A separation type broccoli processing and breaking device

A broccoli and separate technology, which is applied in the field of separate broccoli processing and crushing devices, can solve the problems of waste of energy consumption, inability to adjust the crushing height, and inability to adjust the vertical position of the crushing blade, etc., and achieves flexible and reasonable use, Use flexible and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

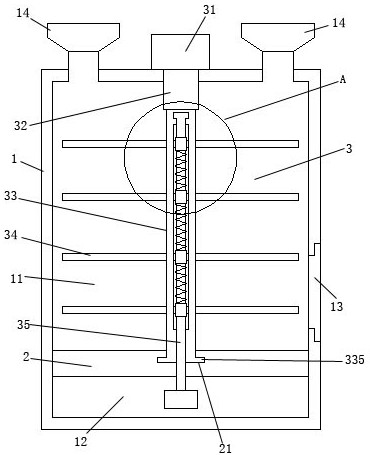

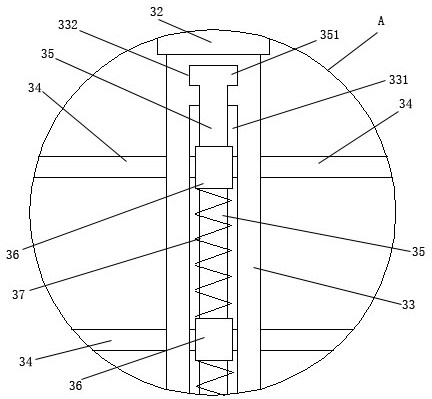

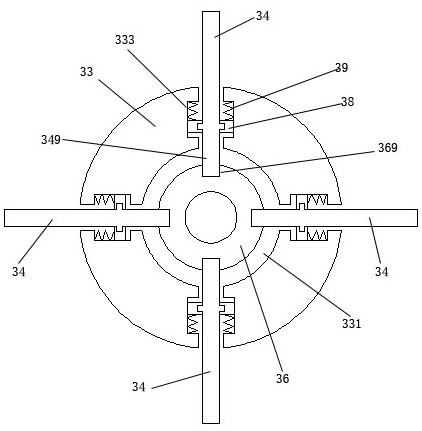

[0018] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0019] Such as Figures 1 to 4 As shown, a separate broccoli processing and breaking device includes a body 1, a closing plate 2, and a breaking mechanism 3; both sides of the upper end of the body 1 are provided with a hopper 14; the bottom of the body 1 is equipped with a closing plate 2. A driving slot 12 is provided below the closing plate 2, and a crushing cavity 11 is provided above the closing plate 2; the crushing mechanism 3 includes a driving motor 31, a rotating shaft 32, a connecting shaft 33, and crushing blades 34 , driving screw 35, floating internal thread cylinder 36, sliding limit block 38, annular elastic body 39; the driving motor 31 is installed in the middle of the upper end of the body 1; the lower end of the driving motor 31 is installed with a rotating shaft 32; the rotating The lower end of the shaft 32 extends to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com