Grading screening and storing device for industrial waste residue harmless treatment

A technology for harmless treatment and industrial waste residues, which is applied in the direction of separating solids from solids by air flow, sieving, solids separation, etc. The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

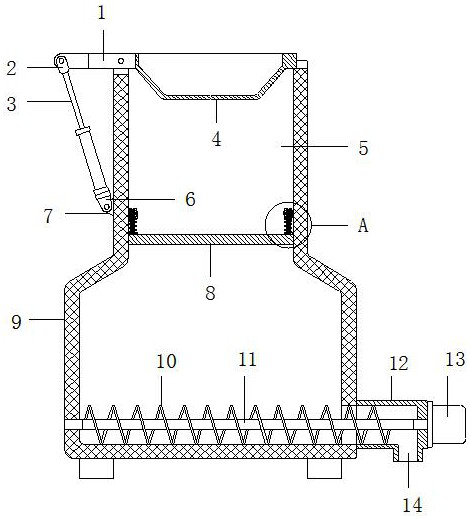

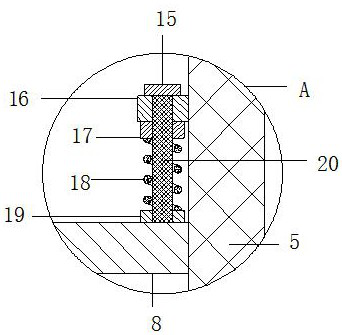

[0020] Such as Figure 1-2 As shown, a sorting and screening storage device for the harmless treatment of industrial waste residues includes a storage bin 9 with an open top, and the mouth of the storage bin 9 is provided with a screening bin 5 communicating with the interior thereof. The mouth of the warehouse 5 is hinged with a coarse screen 4 that can be turned radially outward. The coarse screen 4 is used to filter the floating objects in the industrial waste, and a turning rod 1 is arranged on it. Connected to one end of the hinge between the coarse screen 4 and the storage bin 9, and it is driven by the drive assembly to rotate along the hinge between the coarse screen 4 and the storage bin 9, so that the coarse screen 4 is turned over to the screen On the outside of the bin 5, the filtered and retained floating matter on the coarse screen 4 is poured into an external collection device, and a fine screen 8 that is vertically slid and snapped inside the screen 5 is also p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com