High-precision numerical control flame cutting machine used for steel plate cutting

A flame cutting machine, flame cutting technology, applied in gas flame welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of poor steel plate stability, affecting the accuracy of flame cutting, etc., to improve service life, ensure stability, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

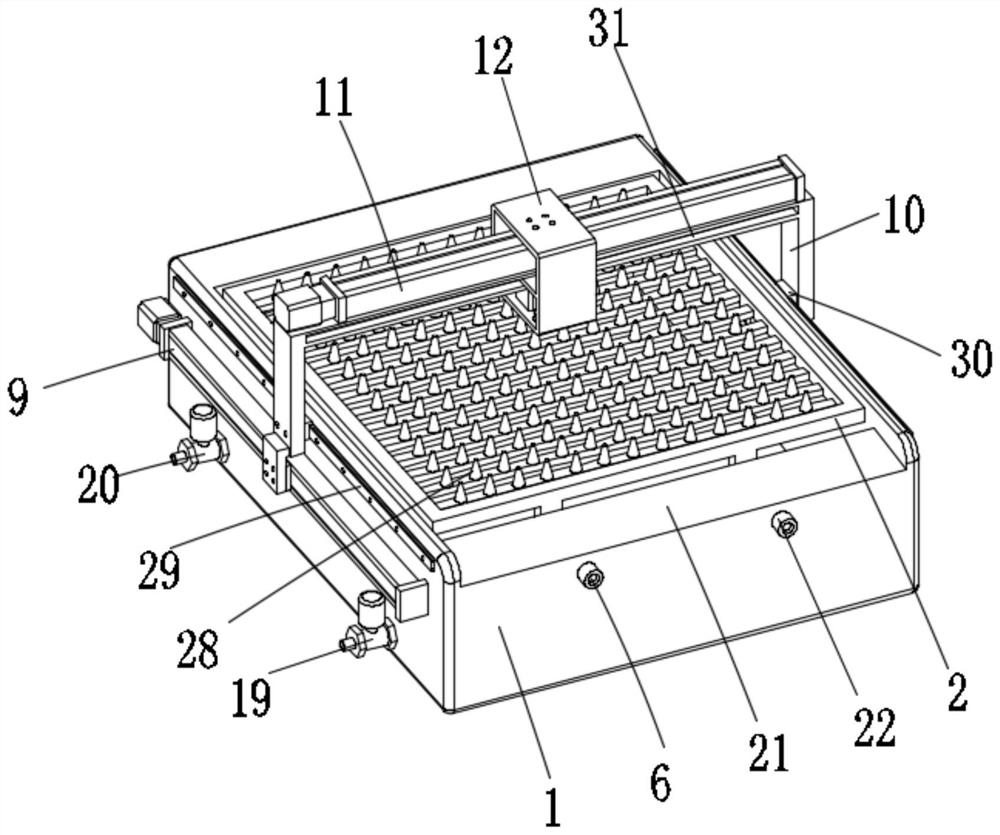

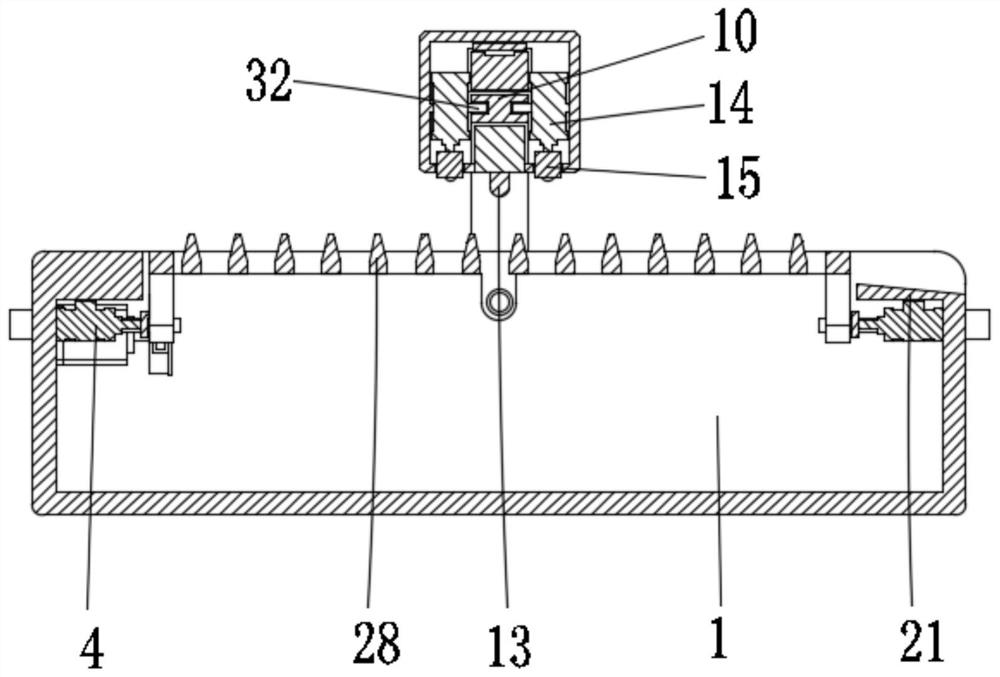

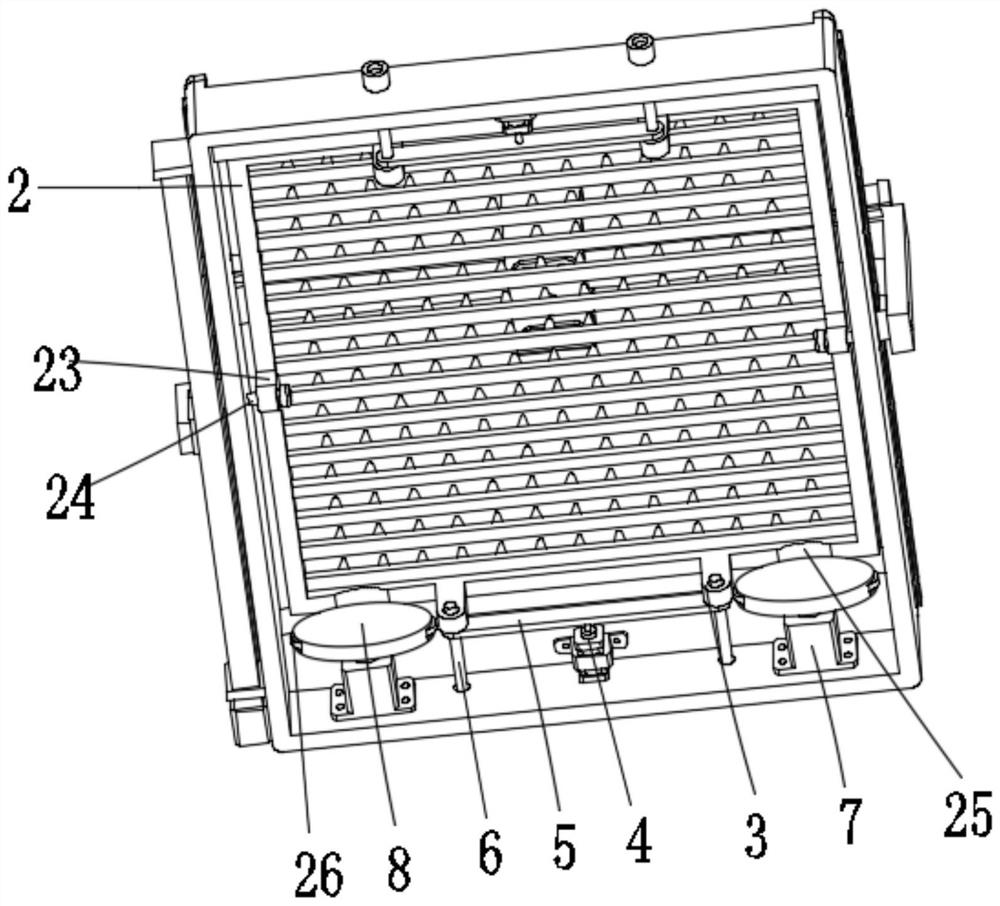

[0032] A kind of high-precision numerical control flame cutting machine that is used for steel plate cutting of the present embodiment, refer to Figure 1-7 : Including the pool 1, the upper side of the pool 1 is hinged with a cutting support bracket 2, the front and rear bottom sides of the cutting support bracket 2 are left and right symmetrically provided with limit holes 3, the front and rear of the pool 1 are equipped with limit mechanisms, and the front of the pool 1 A blanking mechanism is arranged symmetrically on the left and right, and the limiting mechanism includes a limiting cylinder 4 arranged inside the pool 1, a connecting frame 5 arranged at the output end of the limiting cylinder 4, and a limiting rod 6 symmetrically arranged on the left and right sides of the connecting frame 5. The end of the rod 6 far away from the limit cylinder 4 can pass through and pass through the limit hole 3. The unloading mechanism includes a brake servo motor arranged inside the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com