Hardware fastening equipment for high-precision hardware machining

A hardware and high-precision technology, which is applied in the field of hardware fastening equipment for high-precision hardware processing, can solve the problems of increased resistance between the clamping block and the slide rail, vibration of hardware processing, and different heights on both sides, so as to maintain the air hole. Smooth, enhance machining accuracy, reduce friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] as attached figure 1 to attach Figure 5 Shown:

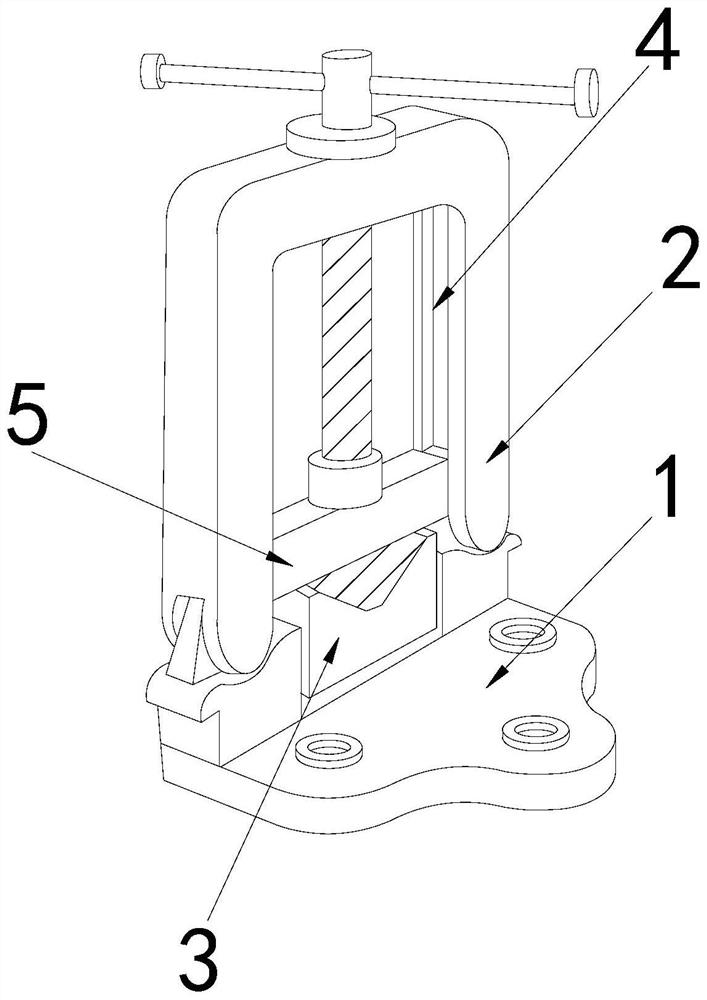

[0028] The present invention provides a hardware fastening device for high-precision hardware processing. Its structure includes a base 1, a bracket 2, a supporting platform 3, a slide rail 4, and a clamping block 5. The bracket 2 is vertically welded on the top of the left end of the base 1. The support platform 3 is located on the top of the base 1 and below the inside of the bracket 2 , the slide rail 4 is recessed on the inner wall of the bracket 2 , and the clamping block 5 is movably matched with the slide rail 4 .

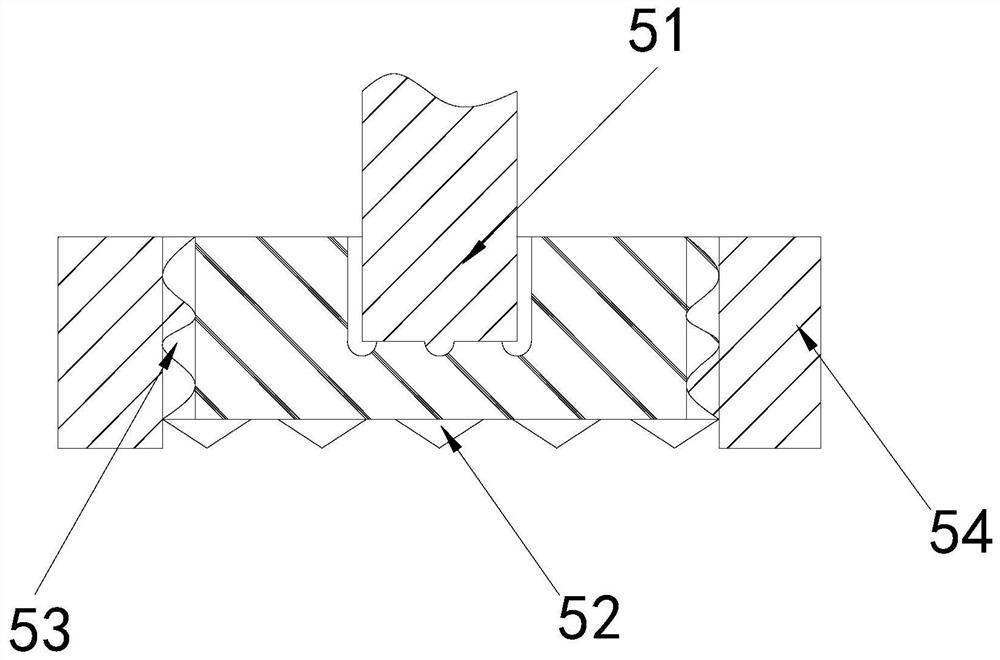

[0029] Described clamp block 5 is provided with screw mandrel 51, teeth 52, connecting block 53, slide block 54, and described screw mandrel 51 is positioned at the middle part of clamp block 5, and described tooth 52 is fixed on clamp block 5 bottom surfaces, and described slide block 54 is installed on both sides of clamping block 5 through connecting block 53.

[0030] Wherein, the slider 54 is p...

Embodiment 2

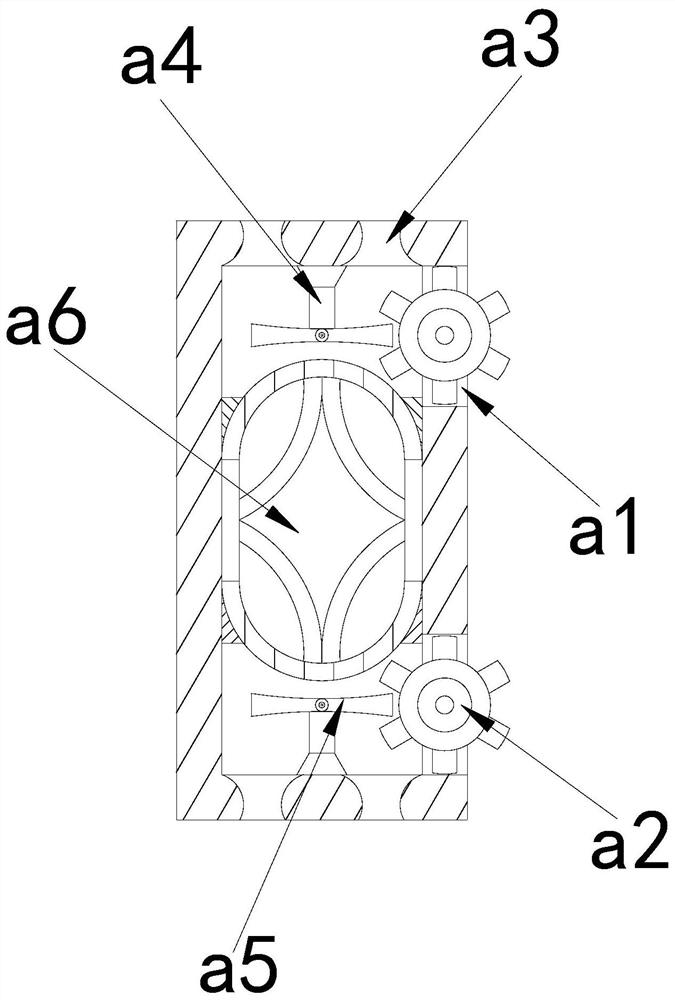

[0036] as attached Image 6 to attach Figure 8 Shown:

[0037]Wherein, the air hole a3 is provided with a bottom groove z1, a pressure plate z2, a reset block z3, and a top block z4, the bottom groove z1 runs through the center of the bottom of the air hole a3, the pressure plate z2 is installed on both sides of the air hole a3, and the reset block z3 is sandwiched between the bottom surface of the pressure plate z2 and the inner wall of the air hole a3, the top block z4 is nested on the top inner wall of the pressure plate z2, and the pressure plate z2 is arc-shaped, which is beneficial to increase the force bearing area with the gas and facilitate the gas to flow along The curved surface of the pressure plate z2 flows.

[0038] Wherein, the top block z4 is provided with a supporting block x1, an air passage x2, and a blocking ring x3, the supporting block x1 is located on both sides of the air passage x2, the blocking ring x3 is installed on the inner wall of the air pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com