Train carriage residual coal sweeper

A technology for sweepers and trains, applied in vehicle cleaning, vehicle cleaning equipment, vehicle maintenance, etc., can solve the problems of low work efficiency, poor applicability, high cost of use and equipment, and achieve improved effect and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]Hereinafter, the preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings, and the present invention will be further explained.

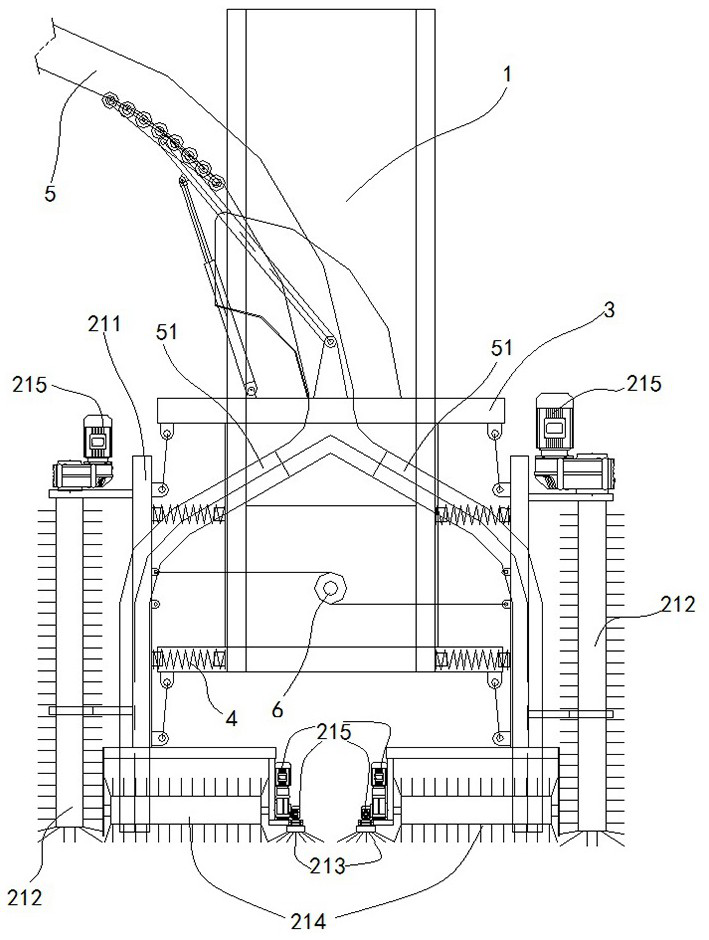

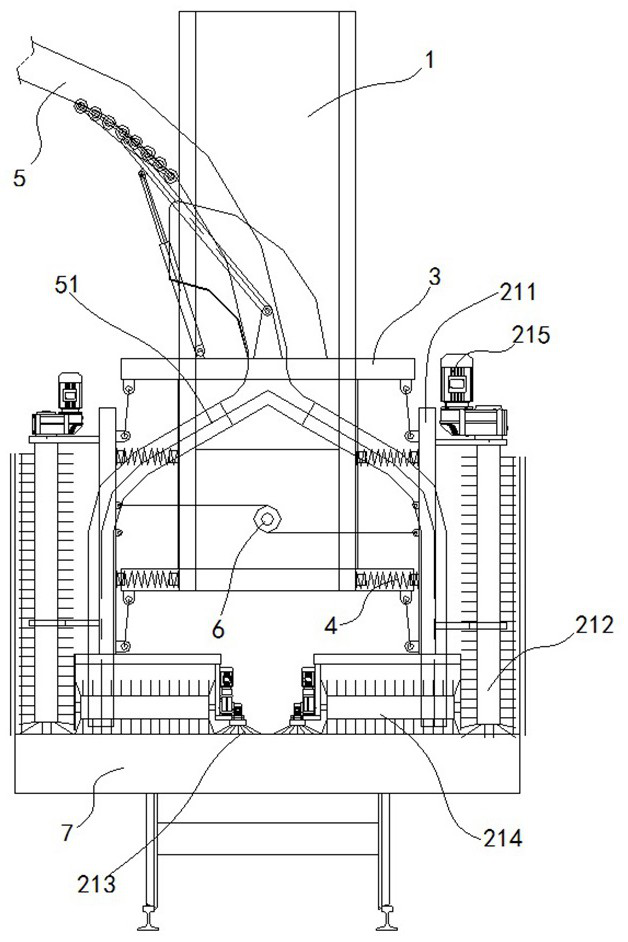

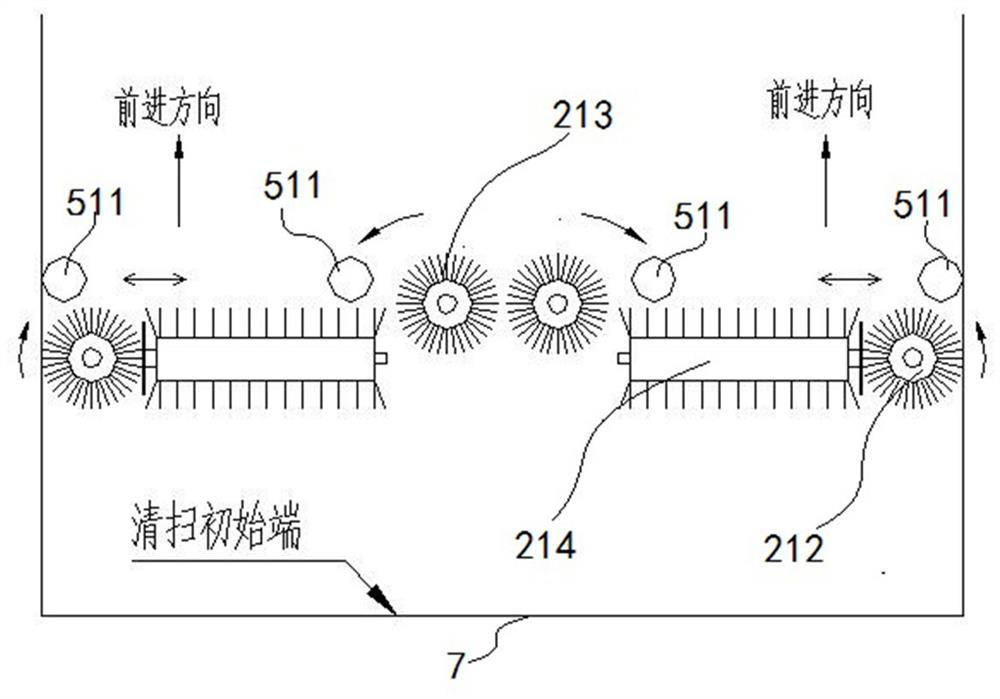

[0033]First, combineFigure 1~4 Describes the train skin waste coal cleaning machine according to the embodiment of the present invention, which is used for cleaning the train skin waste coal, and its application scenarios are very wide.

[0034]Such asFigure 1~2 As shown, the train skin remaining coal cleaning machine according to the embodiment of the present invention has a guide frame 1, a cleaning module, a lifting frame 3, a number of springs 4, and a suction module 5. Among them, the guide frame 1 is set up vertically, and the lifting frame 3 is set in On the guide frame 1, the lifting frame 3 can reciprocate up and down along the guide frame 1. The cleaning module is connected to the lifting frame 3. The lifting frame 3 can drive the cleaning module to move up and down along the guide fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com