A binding mechanism for heating cable production

A technology of heating cable and rotating mechanism, which is applied to the parts of strapping machinery, packaging machines, and strapping objects. It can solve the problems of twisting, deformation, and poor effect of heating cable, and achieve moderate winding tension, avoid deformation, and improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

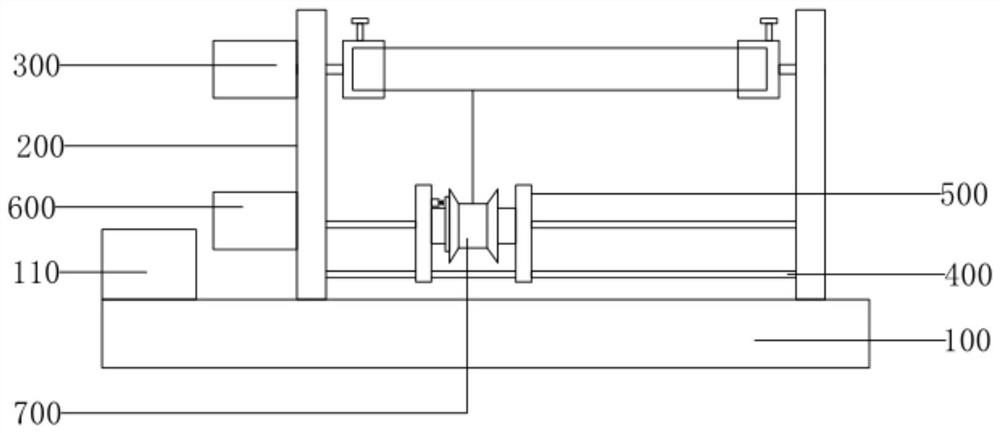

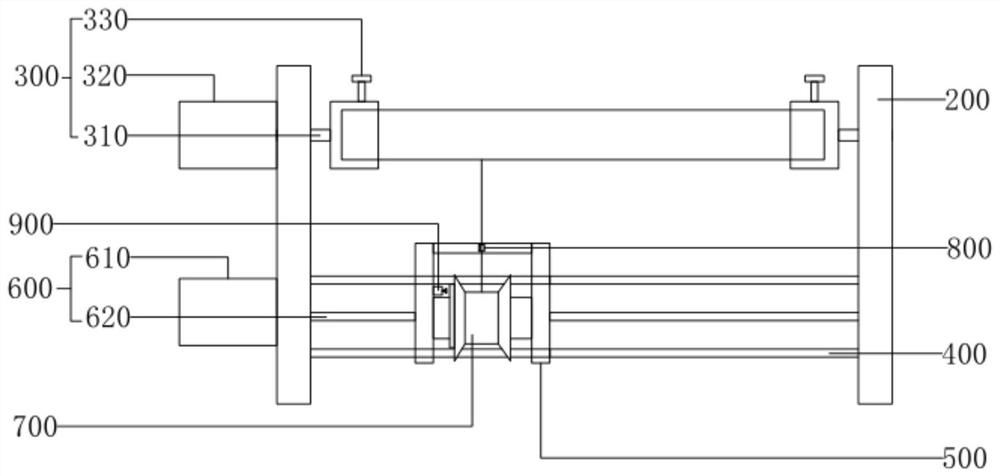

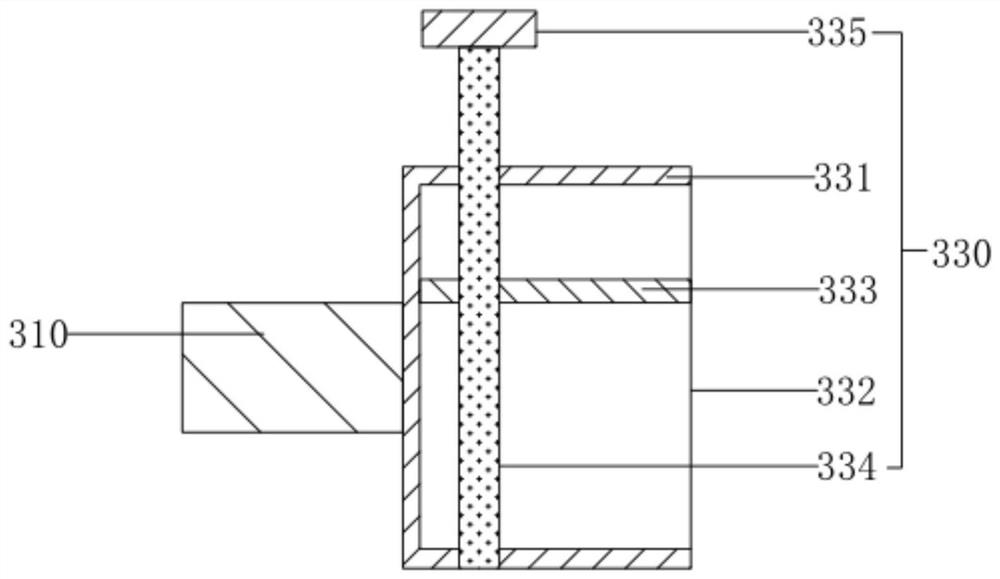

[0025] The present invention provides a binding mechanism for the production of heating cables, see Figure 1-Figure 6 , including a workbench 100, a support plate 200 is arranged on the workbench 100 at intervals, and a rotating mechanism 300 is arranged on the upper side of the support plate 200 to clamp the heating cable and drive the heating cable to rotate; a guide is provided between the two support plates 200 Column 400, a support platform 500 is slidably arranged on the guide column 400, and a drive device 600 is arranged on the support plate 200 to drive the support platform 500 to move along the length direction of the guide column 400; The rotatable winding wheel 700 is provided with a binding rope 710 in the winding wheel 700 . In use, the end of the binding rope 710 on the reel 700 is wound on the heating cable, and the heating cable is clamped by the rotating mechanism 300 and driven to rotate. During the rotation, the binding rope 710 is wound on the heating cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com