Sealing machine for can production based on positioning mechanism

A positioning mechanism and sealing machine technology, applied in the direction of flanged bottle caps, etc., can solve problems such as danger, inability to fit the surface of the can, and misalignment of the seal, so as to facilitate the reset work and protect the surface of the can

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

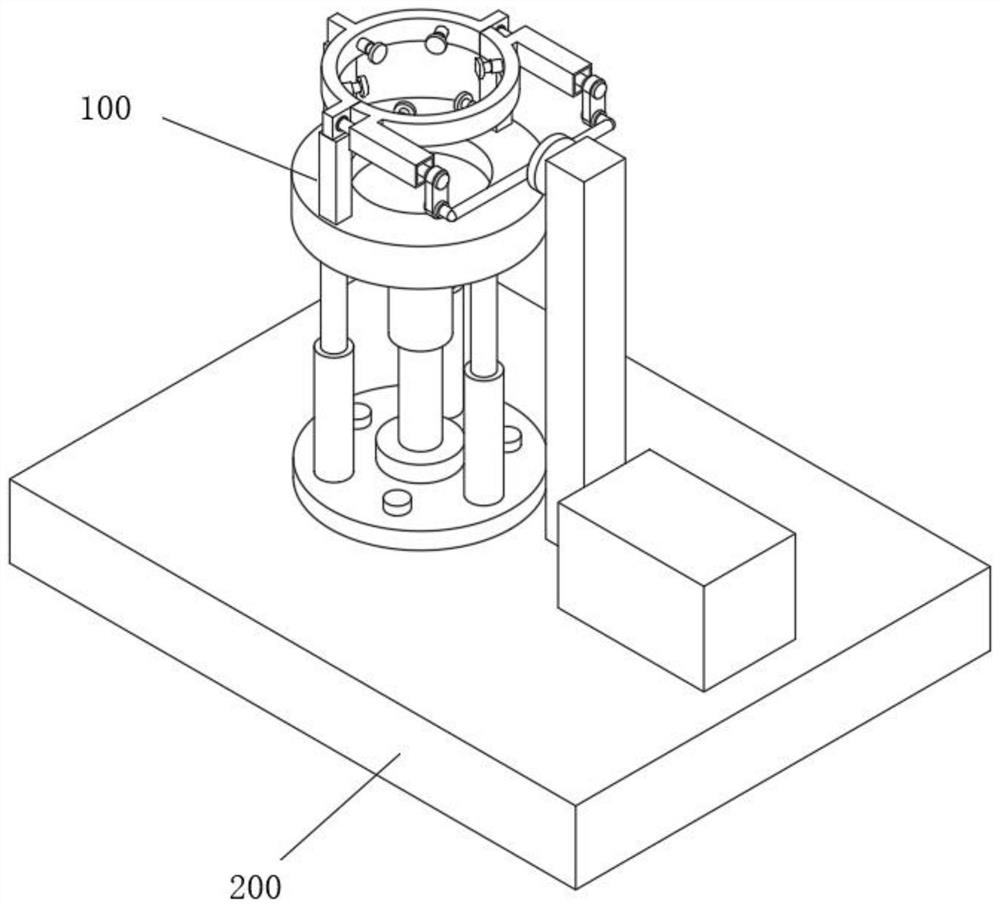

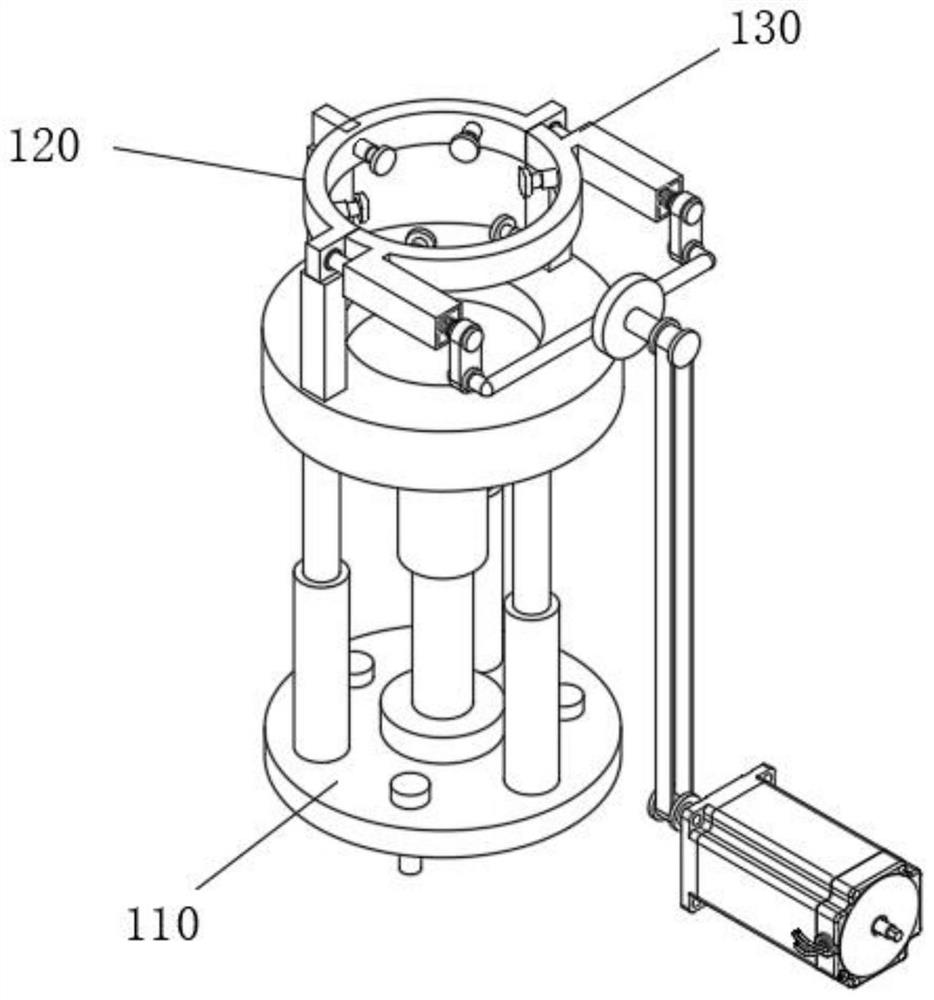

[0057] see Figure 1-Figure 12 As shown, the present embodiment provides a sealing machine for can production based on a positioning mechanism, including an operating platform 200 and a positioning device 100 installed above the operating platform 200, and the positioning device 100 at least includes:

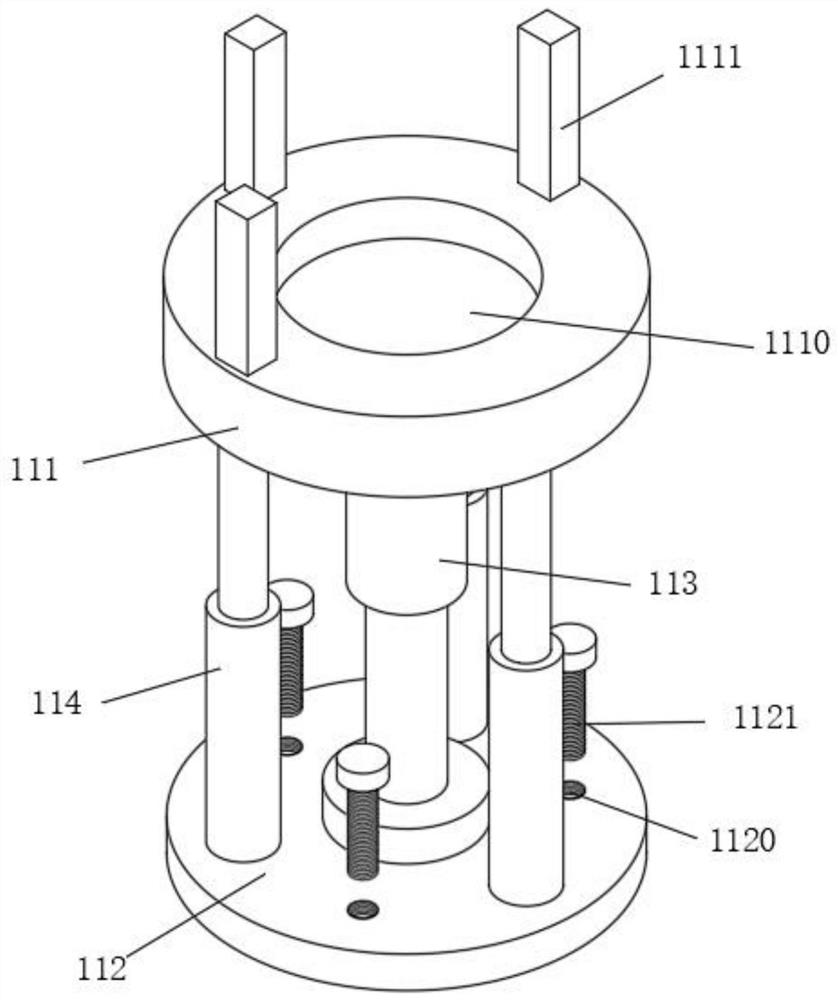

[0058] The supporting device 110, the supporting device 110 includes a fixed seat 111 and a base 112 connected below the fixed seat 111, the upper surface of the fixed seat 111 is provided with a fixed groove 1110, and the upper surface of the fixed seat 111 is located around the fixed groove 1110 and is provided with a support rod 1111 , the bottom end of the fixed seat 111 is fixedly equipped with a hydraulic rod 113, the hydraulic rod preferably adopts a piston type hydraulic rod, and its working principle is as known to those skilled in the art, with gas and liquid as the working medium, composed of pressure tubes, pistons, Composed of a piston rod and multiple connectors, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com