Automatic paving device for geotechnical materials

A geotechnical material and automatic technology, applied in roads, road repairs, roads, etc., can solve problems such as high labor intensity, affecting construction quality and construction progress, and low operating efficiency, so as to ensure construction quality and construction progress, and enhance compaction Combining effects, operation time-saving and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

[0019] In this embodiment, the forward direction of the traveling machine is the front, and vice versa.

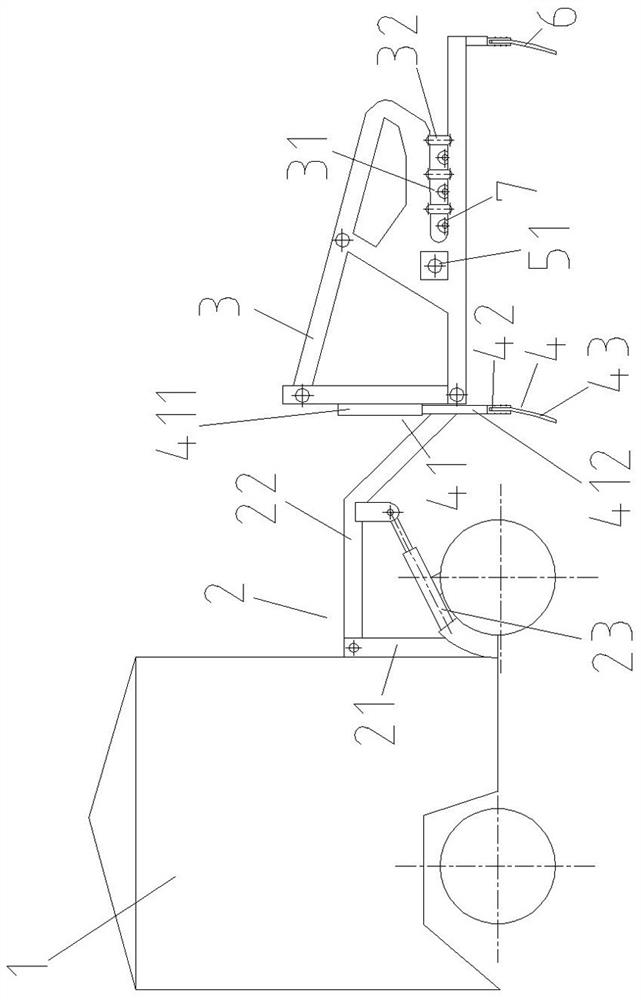

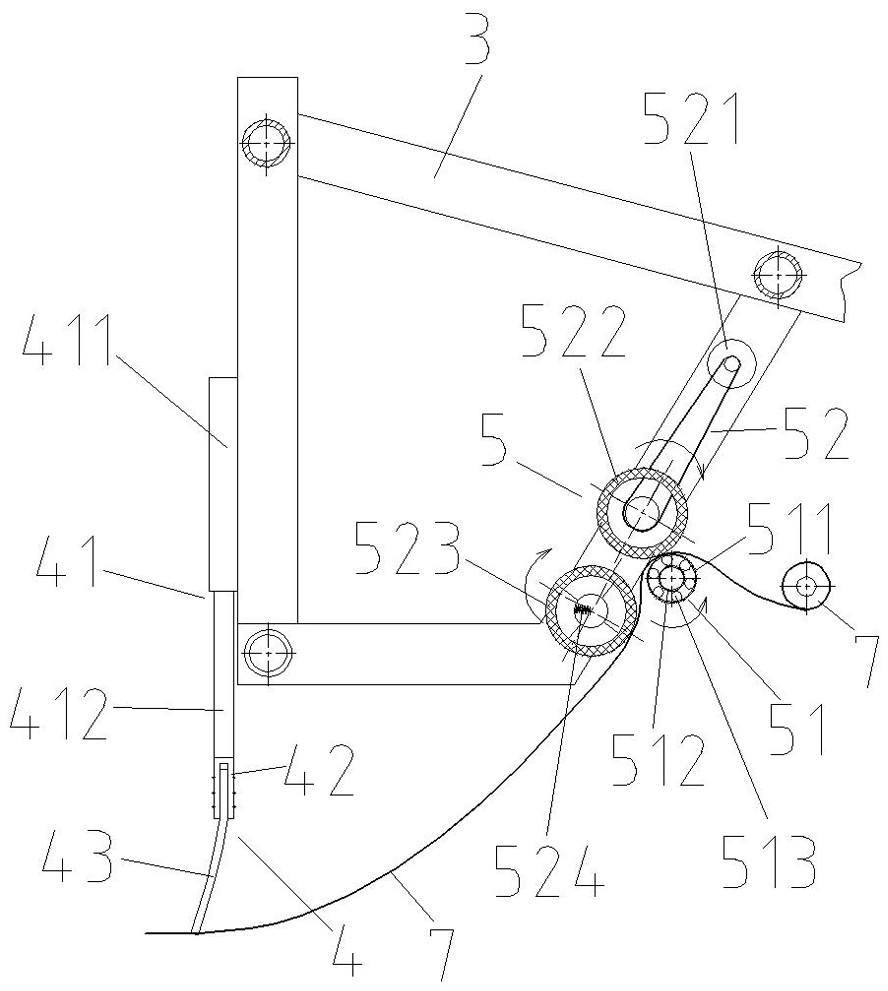

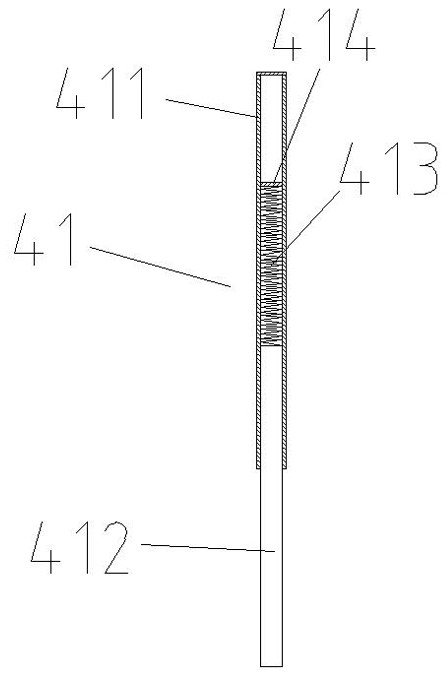

[0020] Such as figure 1 , figure 2 with image 3 Shown, the present invention comprises traveling machine 1, connecting mechanism 2, paving frame 3, is arranged on the compacting mechanism 4 of paving frame 3 rear sides, is arranged on the automatic paving mechanism 5 on paving frame 3 and is arranged on paving frame The miscellaneous rubber pad 6 on the lower front side of the rack 3. The tires of the walking machine 1 can be rolled on the laid geotechnical material 7 to further compact and level the geotechnical material 7 to ensure good bonding between the geotechnical material 7 and the joint surface. Connecting mechanism 2 comprises fixed frame 21, rocking arm 22 and two oblique support oil cylinders 23, and fixed frame 21 is vertically fixed on the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com