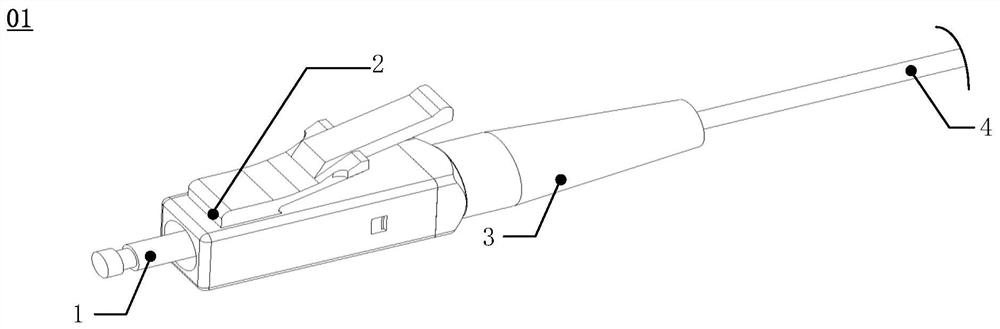

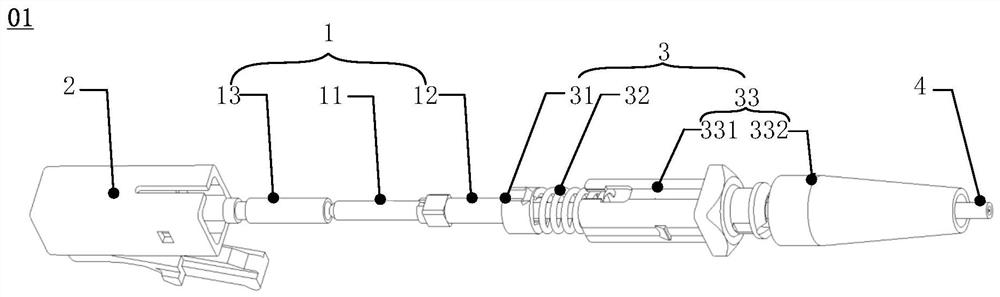

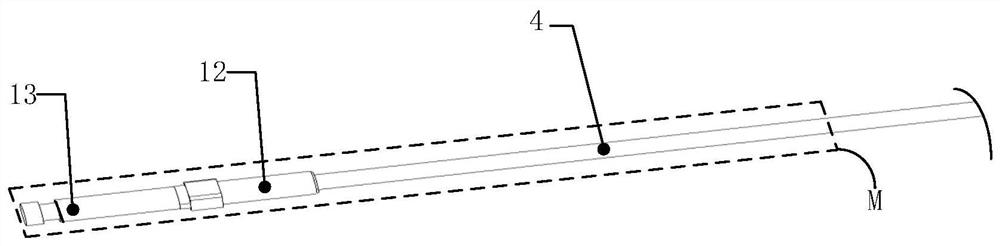

an optical connector

An optical connector and tube-through technology, applied in optics, optical components, instruments, etc., can solve the problems of cumbersome installation process, many FMC connector parts, affecting construction efficiency, etc., to reduce assembly difficulty, simplify connection structure, improve The effect of on-site assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Firstly, the application scenario of this application is introduced: In the field of ODN (optical distribution network, optical distribution network), in order to reduce the difficulty of construction and facilitate subsequent maintenance, the air blowing method can be used to quickly lay optical cables. In a specific air-blowing pipeline, the air-blowing method uses external air-blowing equipment to provide blowing force and forward power, and blows the optical cable to a designated place, and then welds the pigtails on site, or uses FMC (field mountable connector, field mountable connector) ) On-site assembly method to continue the optical cable. However, when the on-site welding method is used, it is necessary to carry proprietary fiber melting equipment, which requires a higher technical level of the construction personnel; when the FMC on-site assembly method is used, there are many FMC structural parts and the installation steps are cumbersome, and the on-site cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com