Single-motor circulating granulation fluidized bed coupled filtering solid-liquid separation equipment

A solid-liquid separation and fluidized bed technology, which is applied in the direction of precipitation separation, separation method, special binder granulation, etc., can solve the problem that the separation area cannot further remove tiny particles of the fluidized bed, the turbidity of the effluent is high, and the double stirring is complicated. Safety and other issues, achieve significant treatment effect, reduce effluent turbidity and suspended solids, reduce equipment installation and post-maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

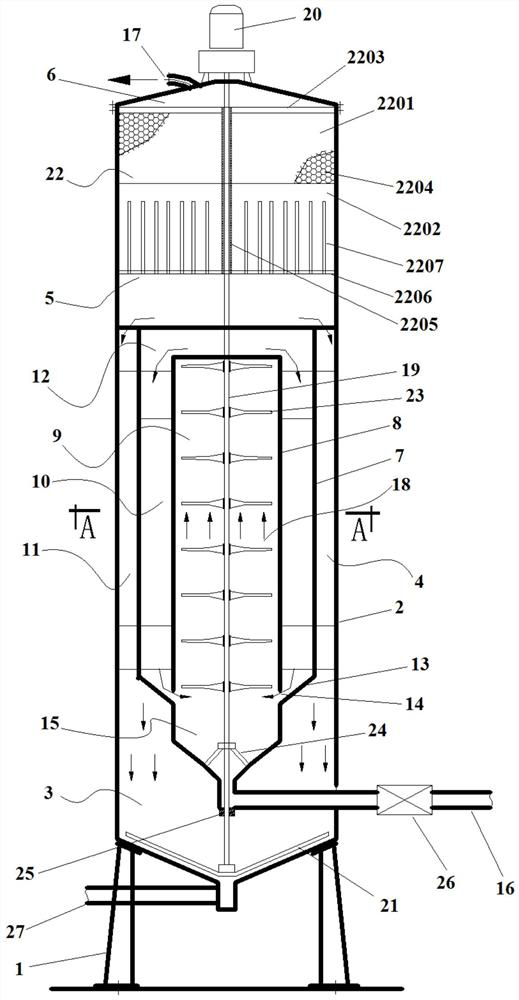

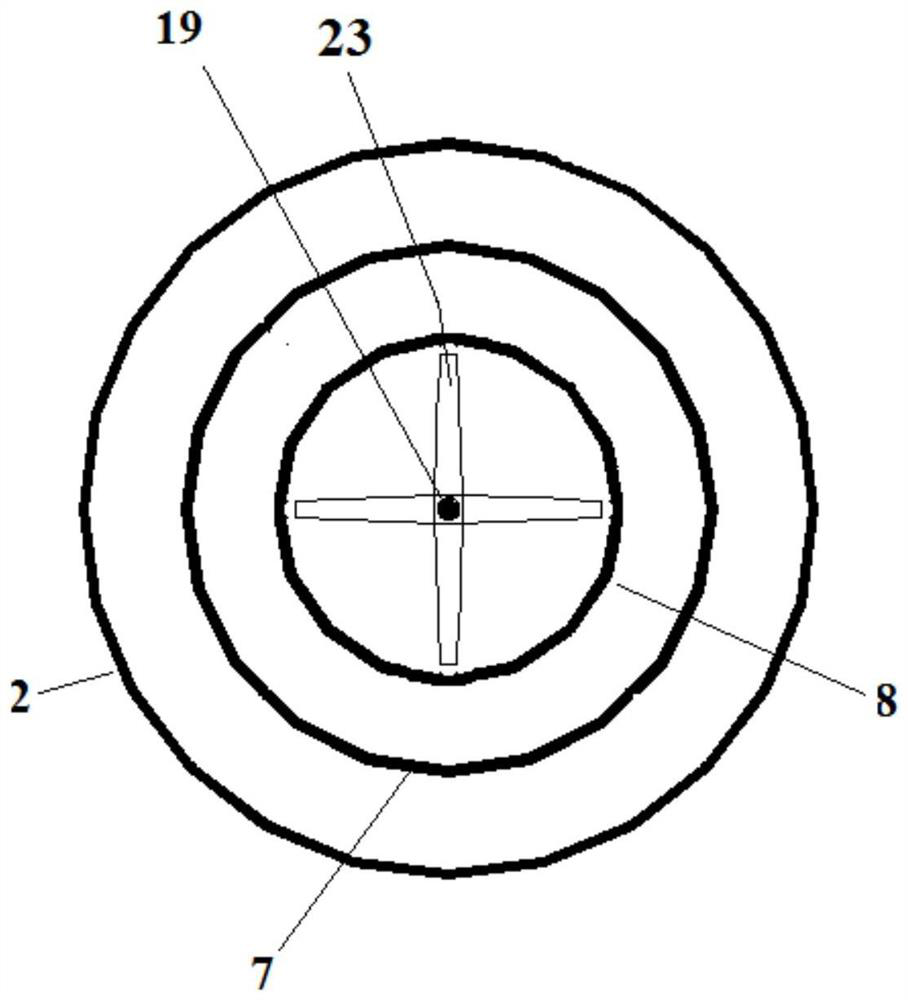

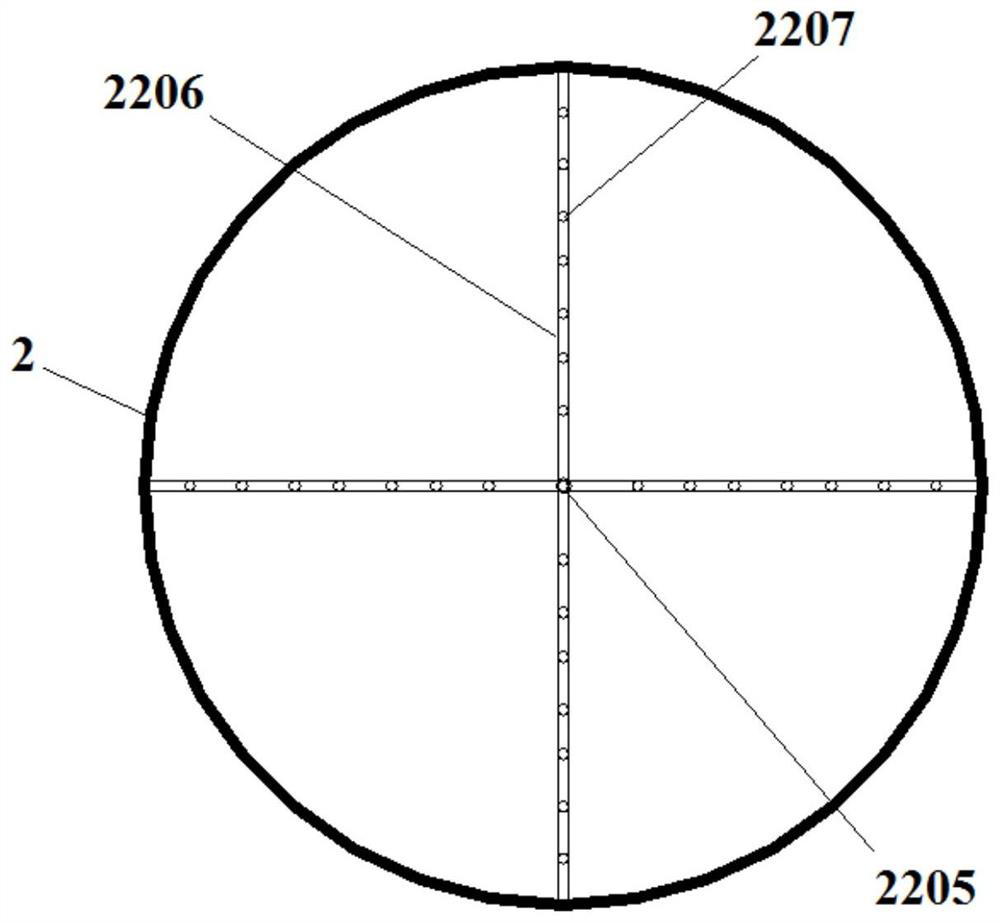

[0042] This embodiment provides a single-motor circulating granulation fluidized bed coupled filtration solid-liquid separation equipment, such as Figure 1 to Figure 3 As shown, it comprises a fluidized bed main device, a stirring device 18 is installed in the inner cylinder 8 of the fluidized bed main device, and the top of the stirring shaft 19 of the stirring device 18 stretches out from the top of the inner cylinder 8, and passes through the fluidized bed main device The separation zone 5 and the water collection zone 6 extend out from the top of the tank body 2 of the fluidized bed main device, and the stirring shaft 19 is driven to rotate by the stirring drive motor 20 installed on the top of the tank body 2;

[0043] Stirring blades 23 are installed on the stirring shaft 19 in the granulation fluidized zone 9 in the inner cylinder 8;

[0044] A water distribution device 24 is fixedly installed at the bottom of the middle cylinder 7 of the main body device of the fluidi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap