Feeding equipment and method for anode refining furnace

The technology of feeding equipment and refining furnace is applied in the field of feeding equipment of anode refining furnace, which can solve the problems of high cost, reduce flue gas temperature, and large flue gas volume, and achieve the effects of compact structure, rapid recovery and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

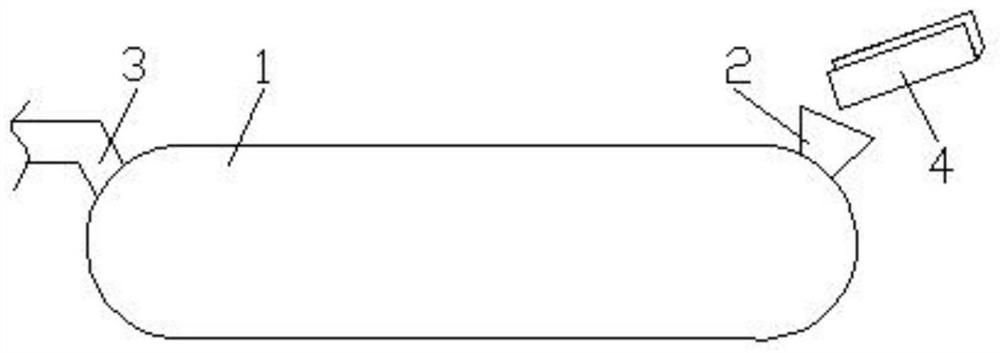

[0026] Example 1

[0027] like figure 1 As shown, in this embodiment, the material guiding mechanism includes a material guiding chute 4, which is fixedly installed between the refining furnace 1 and the blowing furnace slantingly and fixedly, and its two ends extend to the discharge port of the blowing furnace and the blowing furnace respectively. Feeding port 2. When feeding, the hot blister copper produced by the blowing furnace is introduced into the refining furnace 1 from the charging port 2 through the material guide trough 4, and the flue gas generated by the refining furnace 1 is discharged from the exhaust port 3 to realize the separation of charging and exhaust. Simple structure and convenient feeding.

[0028] The above-mentioned material guide trough 4 may be open at one end, that is, the upper end is closed and the lower end is open, and the upper end extends below the discharge port of the blowing furnace, and the hot blister copper produced from the discharge...

Example Embodiment

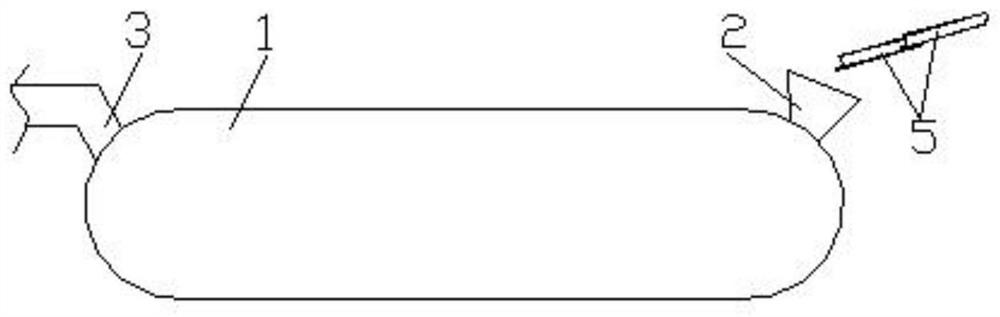

[0030] Example 2

[0031] like figure 2 As shown, in this embodiment, the material guide mechanism includes a plurality of material guide plates 5, and the plurality of material guide plates 5 are distributed in a stepped shape from top to bottom, and each material guide plate 5 is arranged obliquely; In the material plate 5, the upper end of the lower material guide plate 5 extends to below the lower end of the upper material guide plate 5; the lower end of the lowermost material guide plate 5 and the upper end of the uppermost material guide plate 5 extend to the charging port 2 and the blow Furnace outlet. When feeding, the hot blister copper produced by the blowing furnace slides down to the feeding port 2 in turn through the plurality of feeding plates 5 and is added to the refining furnace 1. The plurality of feeding plates 5 can both guide the hot blister copper. In addition, it can buffer the hot blister copper, prevent the hot blister copper from directly falling i...

Example Embodiment

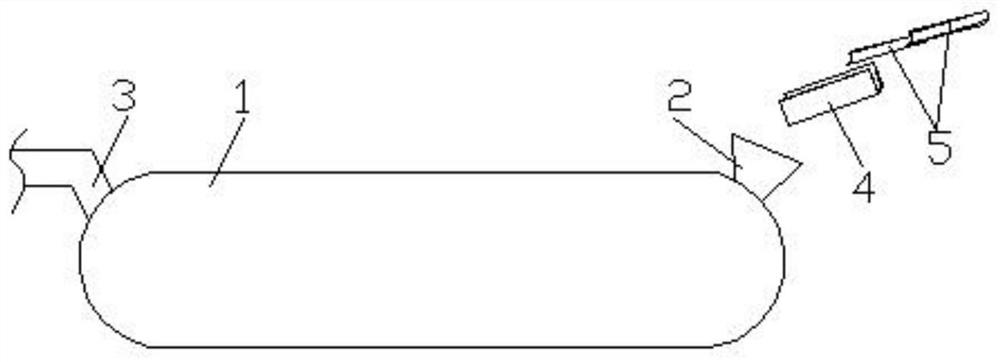

[0034] Example 3

[0035] like image 3 As shown, this embodiment is a combination of Embodiment 1 and Embodiment 2, that is, the material guide mechanism includes a material guide groove 4 and a plurality of material guide plates 5, and the plurality of material guide plates 5 are distributed in a stepped shape from bottom to bottom, and each The guide plates 5 are all inclined; among the two adjacent guide plates 5, the upper end of the lower guide plate 5 extends to the bottom of the lower end of the upper guide plate 5, and the upper end of the uppermost guide plate 5 extends to the blowing The discharge port of the furnace; the material guide groove 4 is obliquely arranged between the lowermost material guide plate 5 and the charging port 2 , and its lower end extends to the charging port 2 . When feeding, the hot blister copper produced by the blowing furnace slides down to the feeding port 2 in turn through the plurality of feeding plates 5 and is added to the refining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com