Roll-to-roll vacuum coating equipment for coating anti-fingerprint film

A vacuum coating, roll-to-roll technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problems of low spraying precision, poor film uniformity, unstable process, etc., to improve production Efficiency and the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

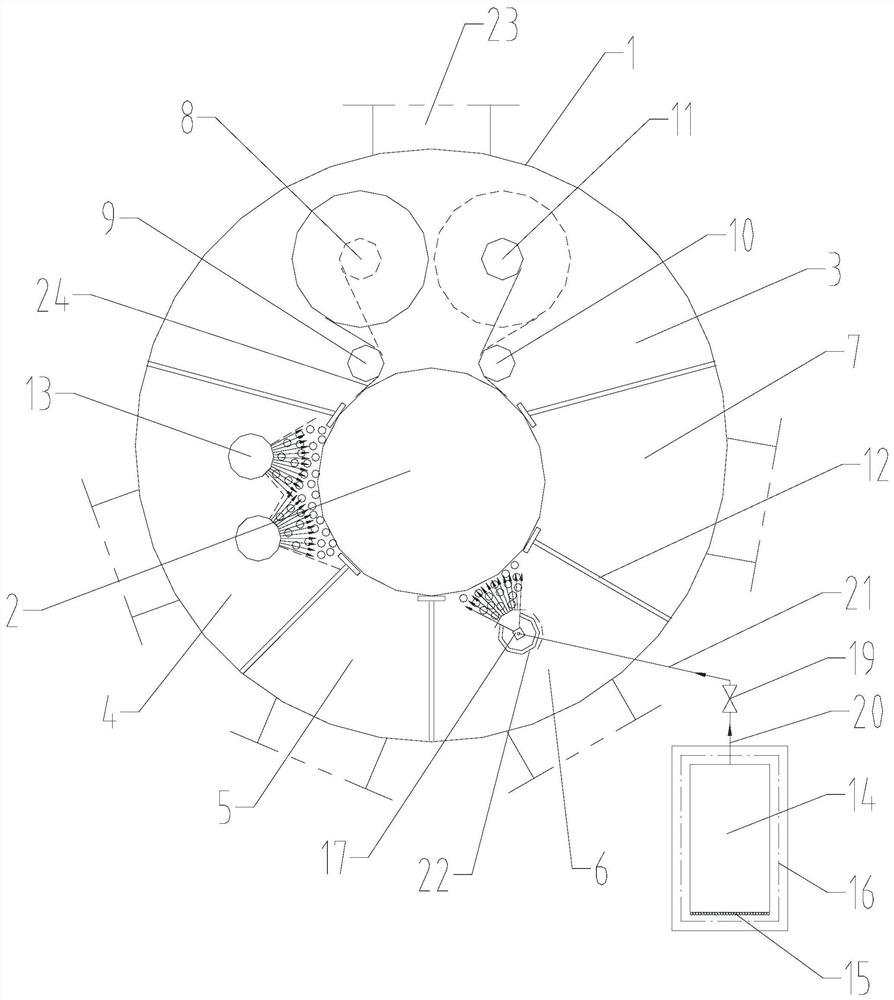

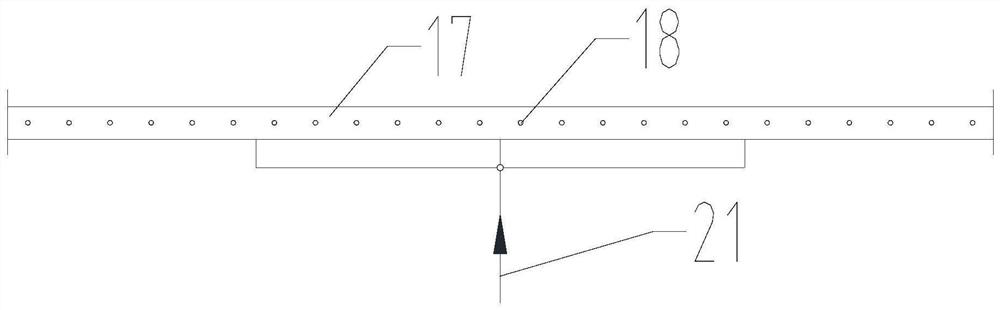

[0023] Such as figure 1 As shown, a roll-to-roll vacuum coating equipment for coating anti-fingerprint film includes a vacuum chamber, a coating roller is arranged in the vacuum chamber, and a rewinding and unwinding chamber arranged in sequence along the circumferential direction of the coating roller, a magnetron sputtering coating chamber, the first air compartment, the gaseous evaporation coating chamber, and the second air compartment; the unwinding and unwinding chamber for winding the base material is equipped with an unwinding roller, a first guide roller, a second guide roller and a winding roller, The substrate coming out of the unwinding roller passes through the first guide roller, the coating roller, the second guide roller, and the take-up roller in turn. The magnetron sputtering coating room is equipped with a magnetron sputt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com