Ceiling module for building a clean room

A ceiling and clean room technology, applied in the field of ceiling modules, can solve problems such as complicated installation of air supply devices, and achieve the effects of saving time consumption, simplifying installation, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

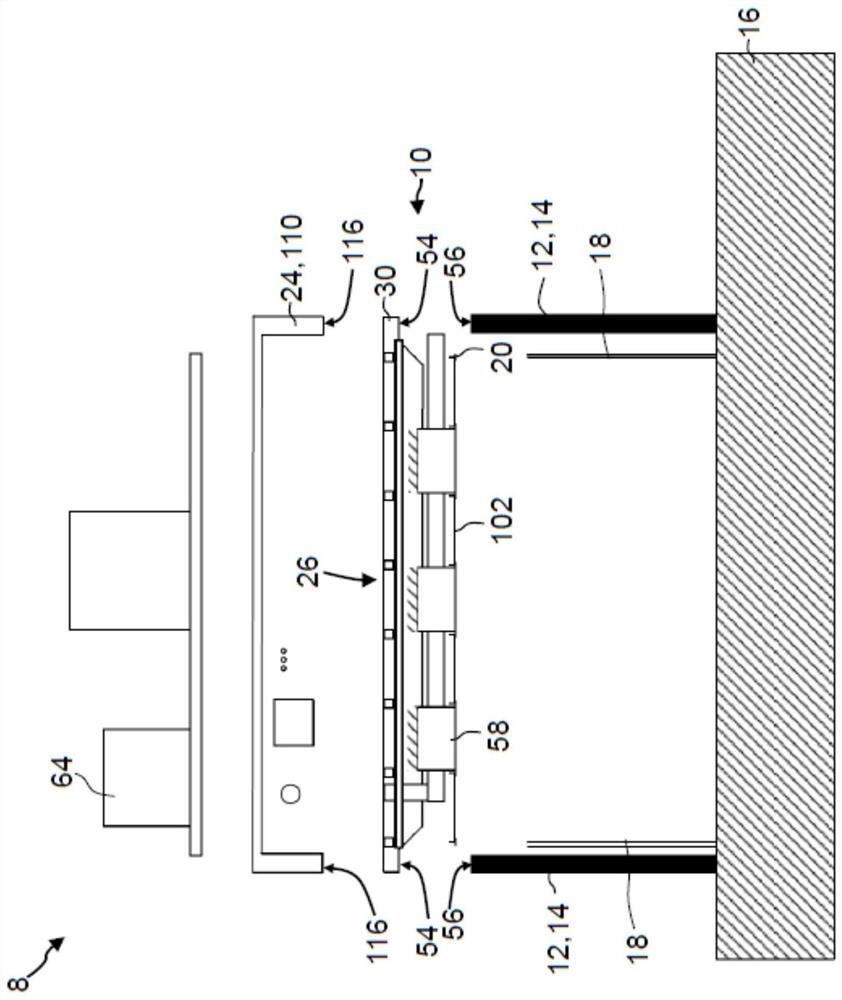

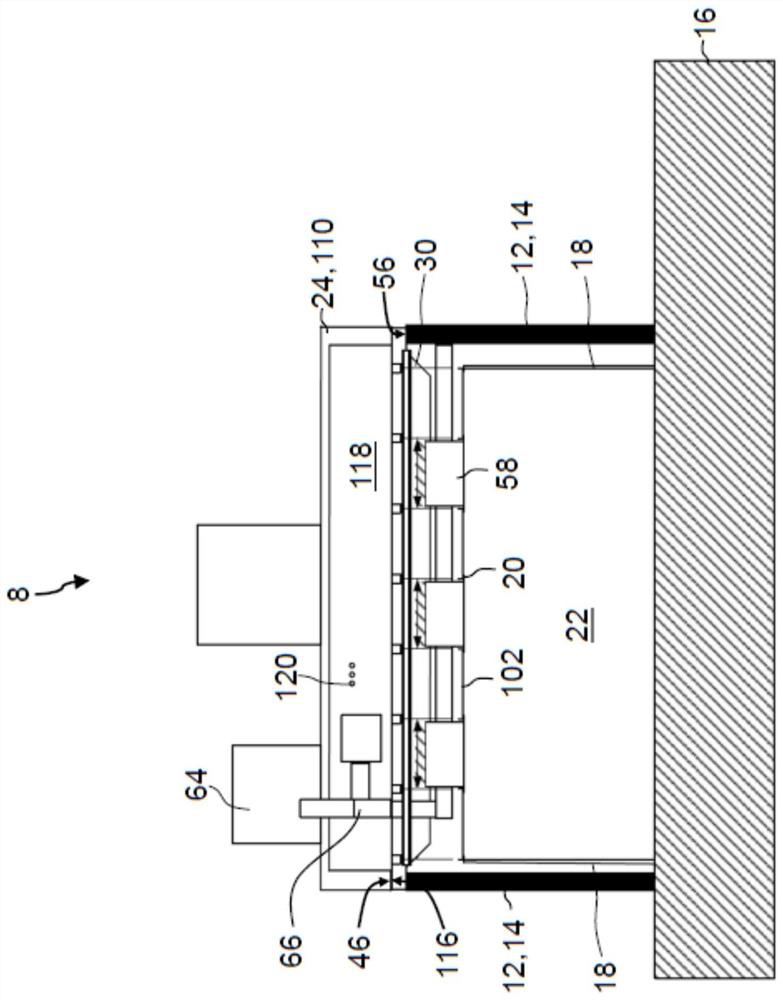

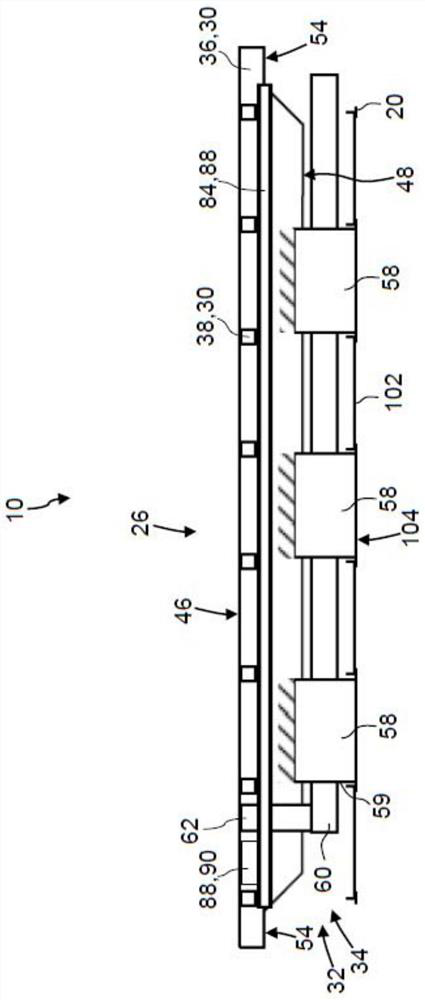

[0069] figure 1 A system for constructing a clean room compartment generally indicated at 8 is outlined. This cleanroom compartment is 8 in figure 2 shown in the fully assembled state.

[0070] The system includes a ceiling module 10 which is figure 2 In the installed state shown, it is arranged on and connected to a support structure 12 . In the present example, the support structure 12 is formed by pillars 14 , such as steel beams, arranged particularly vertically on a foundation 16 . Foundation 16 may be a building floor.

[0071] The system also comprises a plurality of clean room side wall elements 18 which, in the assembled state of the clean room compartment 8, cooperate with the ceiling support 20 of the ceiling module 10 and together define the clean room plenum 22, which is the actual clean room area of clean room compartment 8 (see figure 2 ).

[0072] The system also comprises a holder 24 which is arranged on the upper side 26 of the ceiling module 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com