Waterproof band, waterproof structure between prefabricated parts and construction method of waterproof structure

A technology of prefabricated components and water barriers, which is applied in earth-moving drilling, wellbore lining, tunnel lining and other directions, can solve the problem that the gasket is difficult to ensure water-proof and waterproof effectiveness, and achieves simple structure, guaranteed waterproof effect, and convenient construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

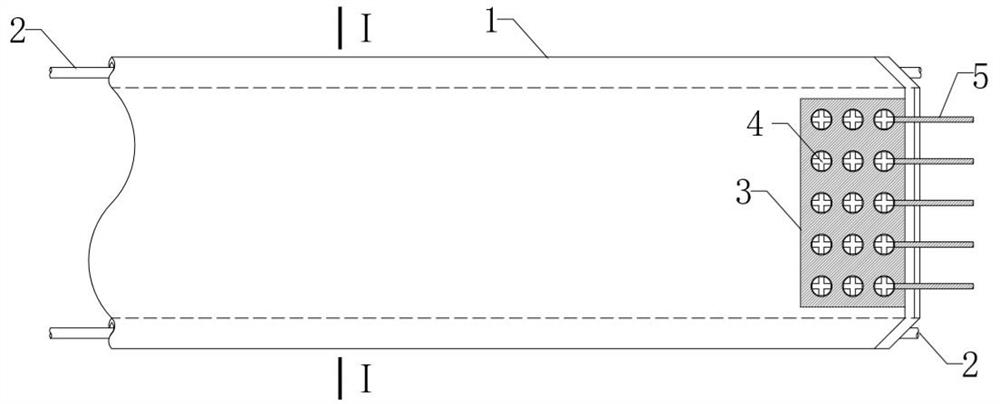

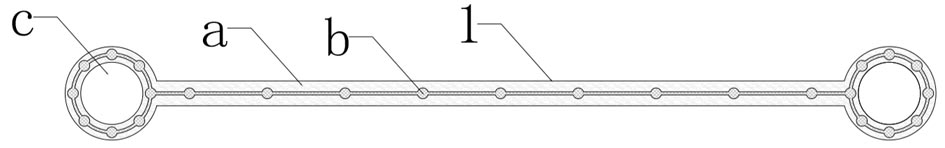

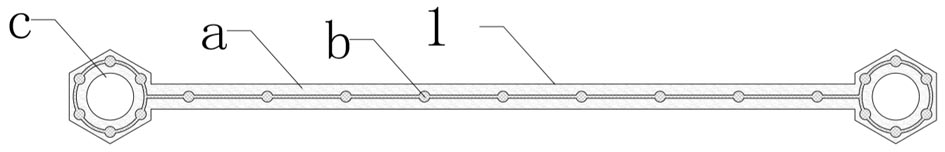

[0049] Such as Figure 1~4 As shown, a water-resistant belt, the water-resistant belt 1 includes belt ends at both ends and a plate belt in the middle, the belt ends are thicker than the plate belt, and the belt ends are used to be installed in a reserved channel. The section of the belt end is circular, polygonal or triangular, and the section of the belt end matches the section of the reserved channel, and the specification of the section of the reserved channel is slightly larger than that of the belt end. There is a cavity c in the end of the belt, and the cavity c is used to pass through the in-band grouting pipe 2, and the in-band grouting pipe is used for the lubrication and cleaning of the reserved channels or the grouting of the cavity, and the construction is completed in the water barrier Finally, grouting in the cavity expands the belt end of the flexible waterproof material.

[0050] The water-proof belt 1 is a flexible water-proof material, preferably a flexible...

Embodiment 2

[0052] Such as Figure 5~8As shown, a waterproof structure between prefabricated components of the above-mentioned water-resistance belt includes prefabricated components, and the prefabricated components are pipe joints. The opposite end faces of the joints, or the outer end faces adjacent to the opposite end faces of two adjacent pipe joints. Specifically, the pipe joints include upper and lower pipe joint permanent structures 6 (such as concrete and steel structures) and left and right pipe joint temporary structures 7 (such as steel structures), and the reserved channels d are arranged on the pipe joint permanent structures 6 .

[0053] The installation of the water-repellent belt needs traction. The front side of the water-resistant belt 1 is connected with the traction rope 5 through the steel splint 3, the rivet 4, and the traction rope 5 is connected with the traction equipment 11. The traction equipment can adopt a hoist. Through the dragging of the traction equipmen...

Embodiment 3

[0058] A construction method of the above-mentioned waterproof structure between prefabricated components includes the following steps.

[0059] Step a, such as Figure 13 As shown, when the prefabricated components are produced, the pre-buried channels are constructed according to the needs. After the prefabricated components are assembled and constructed, the drilling construction of the traction holes of the water barrier is carried out. The drilling equipment 10 is used to drill the traction holes on the outside of the prefabricated components. The component gap is drilled from one end of the working well to the other end of the working well, and the rear end of the drilling device 10 is connected with the traction rope 5 . Such as Figure 14 As shown, after the traction hole is penetrated, the drilling equipment is removed, and the traction equipment 11 is installed to install the water barrier 1 .

[0060] Step b, such as Figure 15 As shown, the installation and cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com