Semiconductor structure and forming method thereof

A technology of semiconductor and segment structure, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve problems such as missing segments, and achieve the effect of improving accuracy and enhancing protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] As mentioned in the background, the precision of the pattern formed by the semiconductor structure in the prior art is poor.

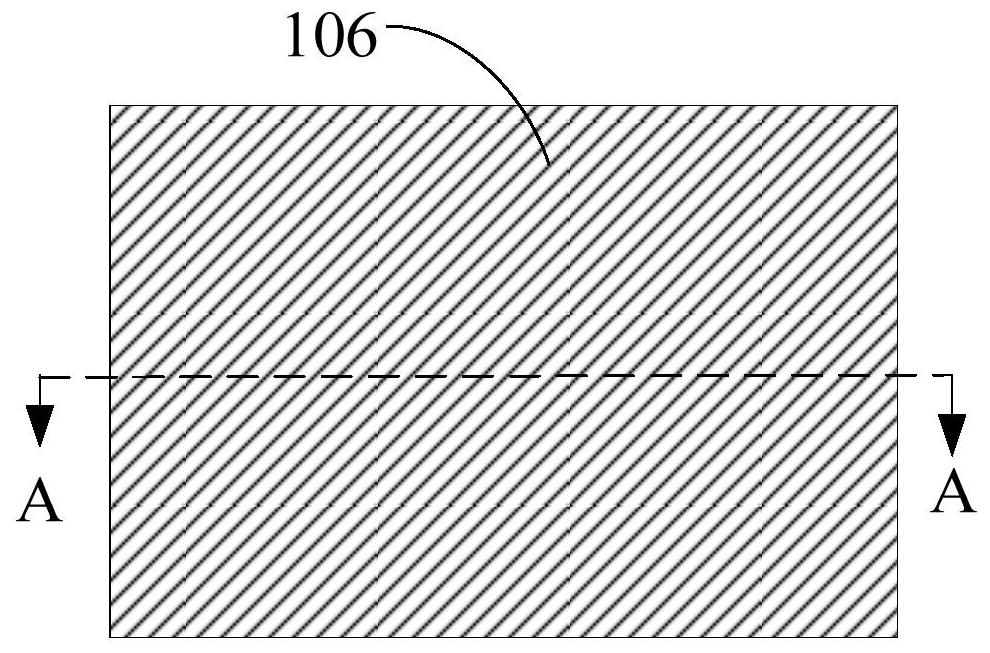

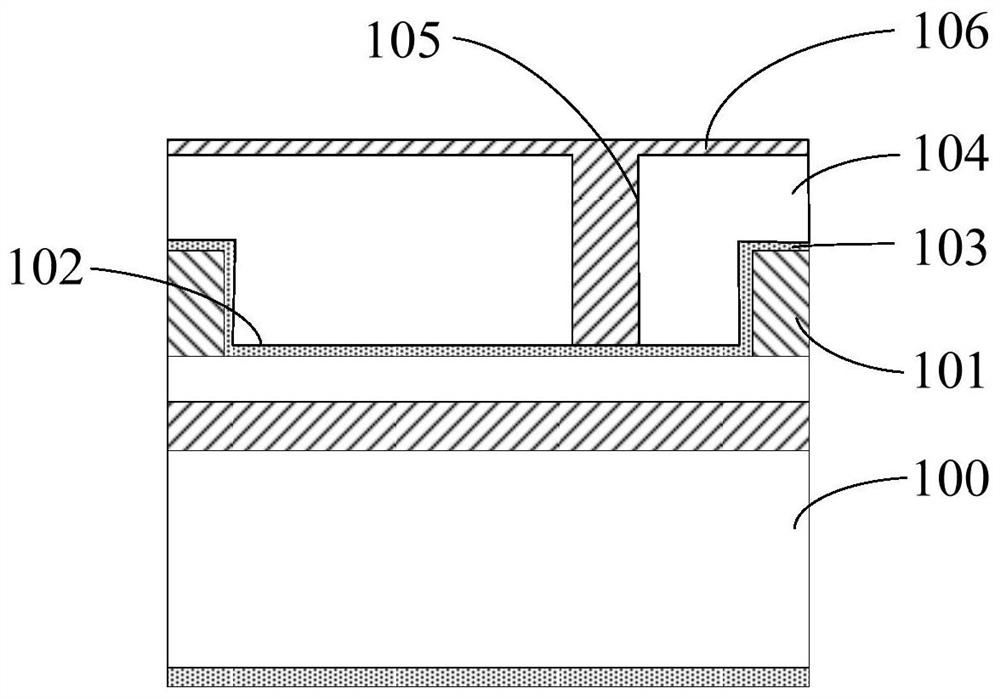

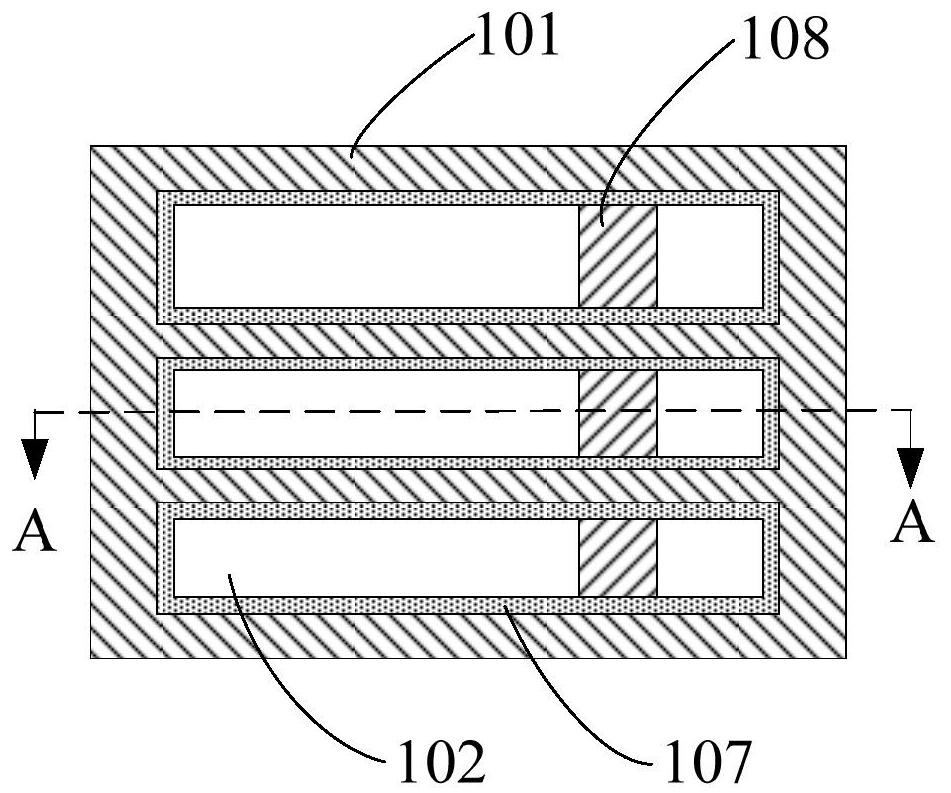

[0032] Please refer to Figure 1 to Figure 2 , figure 2 Yes figure 1 A schematic cross-sectional view along the A-A line provides a layer to be etched 100; a core layer 101 is formed on the layer to be etched 100, and a first trench 102 is provided in the core layer 101, and the first trench 102 is formed along the first trench 102. Extending in one direction, a sidewall layer 103 is formed on the top surface of the core layer 101 and the sidewall and bottom surface of the first trench 102; a sacrificial layer 104 is formed on the sidewall layer 103, and the sacrificial The layer 104 has a split opening 105 exposing the first trench 102 , and a split segment layer 106 is formed in the split opening 105 , and the split segment layer 106 fills the split opening 105 .

[0033] After forming the segment layer 106, planarize the sacrificial laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com