Binding machine

A technology of binding machine and binding wire, which is applied in the fields of application, cultivation, agriculture, etc. It can solve the problems of high steel wire specifications, complex internal structure, and poor overall versatility, and achieve the effect of improving binding efficiency, simplifying structure, and fast binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

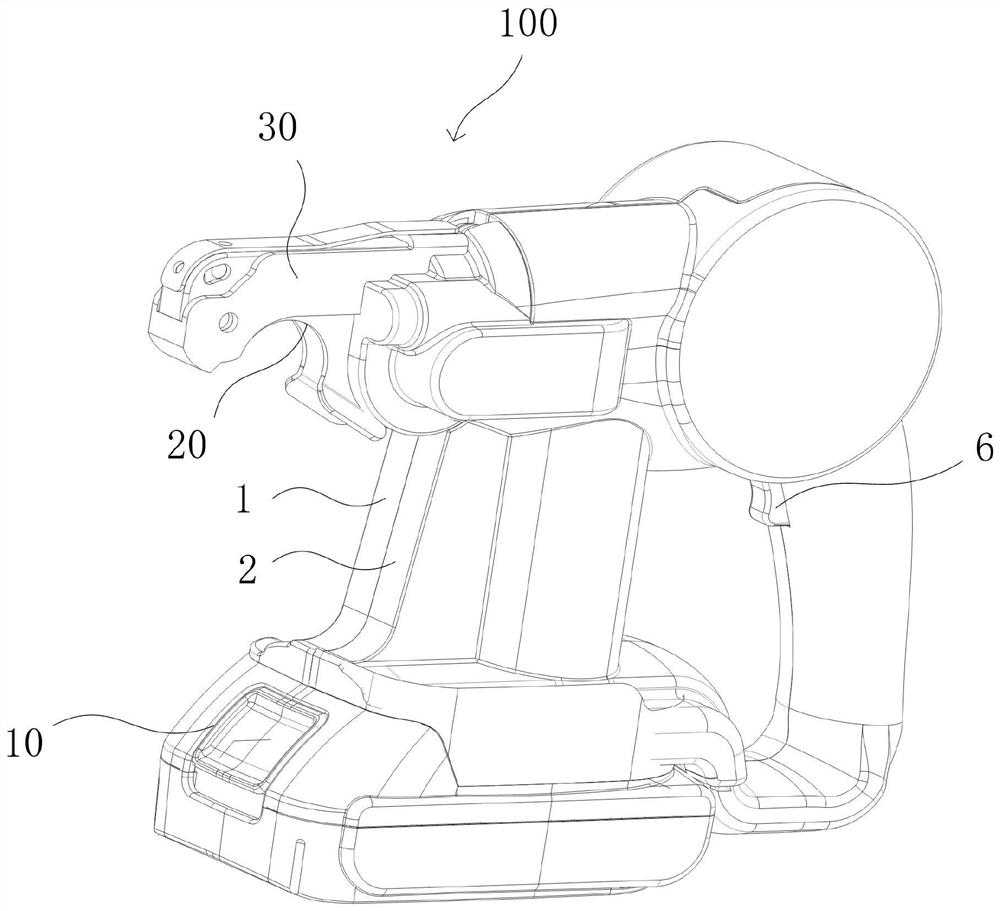

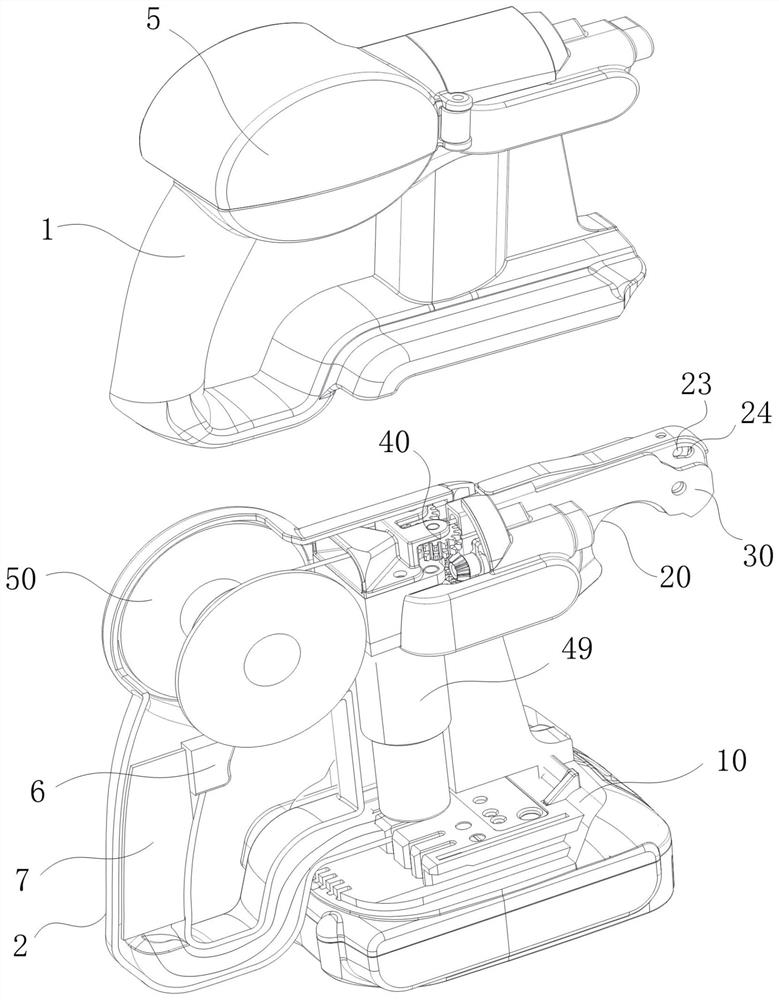

[0046] see figure 1 and figure 2 , a strapping machine 100 including a driving part 49 , a cutting part 30 , a transmission part 40 and a strapping part 20 .

[0047] Specifically, the transmission part 40, the transmission part 40 is driven by the driving part 49, and the binding wire is driven by the transmission part 40 to move to the binding part 20; The binding coil is formed; the cutting part 30 is connected with the transmission part 40 in transmission, and the binding coil is cut off from the binding line through the cutting part 30 . The binding part can quickly bind the plants and vines, and the set binding part can change the conveying path of the binding wire, so that the binding wire used for binding can be automatically wound around the surface of the vines in the form of a ring to realize binding; greatly improved The binding efficiency reduces the labor intensity of people; the cutting part set can quickly cut the binding line, which improves the work effici...

Embodiment 2

[0049] This embodiment is a further optimization scheme on the basis of embodiment 1:

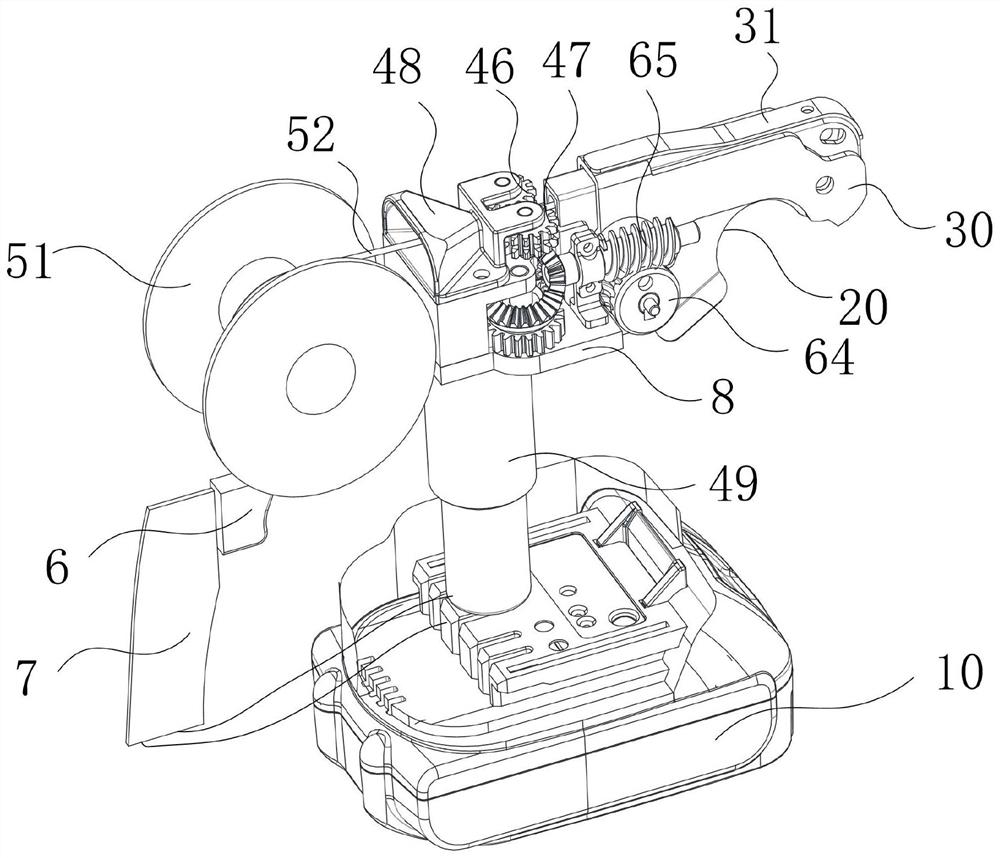

[0050] see Figure 4 , the driving part 49 can drive the transmission part 40 to rotate forward or reversely. When the transmission part 40 rotates forward, it drives the binding wire to move continuously to the binding part 20; The action cuts the lashing coil from the lashing wire. Through the forward and reverse rotation of the transmission part, the binding part and the shearing part are controlled to complete the binding and cutting actions respectively, which greatly improves the work efficiency, and the transmission mode of the whole transmission part is simple and efficient, which makes the overall structure of the strapping machine more streamlined and convenient. Install.

[0051] Further, see Figure 5 , the driving part 49 includes a power output shaft one 42, and the transmission part 40 includes a driving wheel one 43 and a driving wheel two 61 respectively connected to the...

Embodiment 3

[0058] This embodiment is a further optimization scheme on the basis of embodiment 2:

[0059] Further, see Figure 4 and Figure 5 The shearing part 30 includes a shearing power part (not shown in the figure), and the shearing power part includes a worm 65 , and the worm 65 is in driving connection with a driven wheel 2 63 through a driven wheel 3 62 . It is convenient for the secondary rotation of the driven wheel to drive the rotation of the worm, so as to realize the transmission of force.

[0060] Further, the shearing part comprises a shearing knife 32 and a shearing transmission part 60, the shearing transmission part comprises a transmission housing 33, a shearing power part and a cam 67, and the shearing power part is driven by the shearing transmission part 60 to drive the cam 67 to rotate , thereby driving the transmission housing 33 to move upwards, and then driving the shearing knife 32 to trim the thread. The cam is driven by the shearing power part to provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com