Downward-moving bending machine

A technology of a bending machine and a frame, applied in the field of bending machines, can solve the problems of wasting time, reducing the practicability of the bending machine, reducing the production efficiency of workpieces, etc., to improve efficiency, effectively adjust and quickly replace and install, and improve practical sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is attached Figure 1-6 The application is described in further detail.

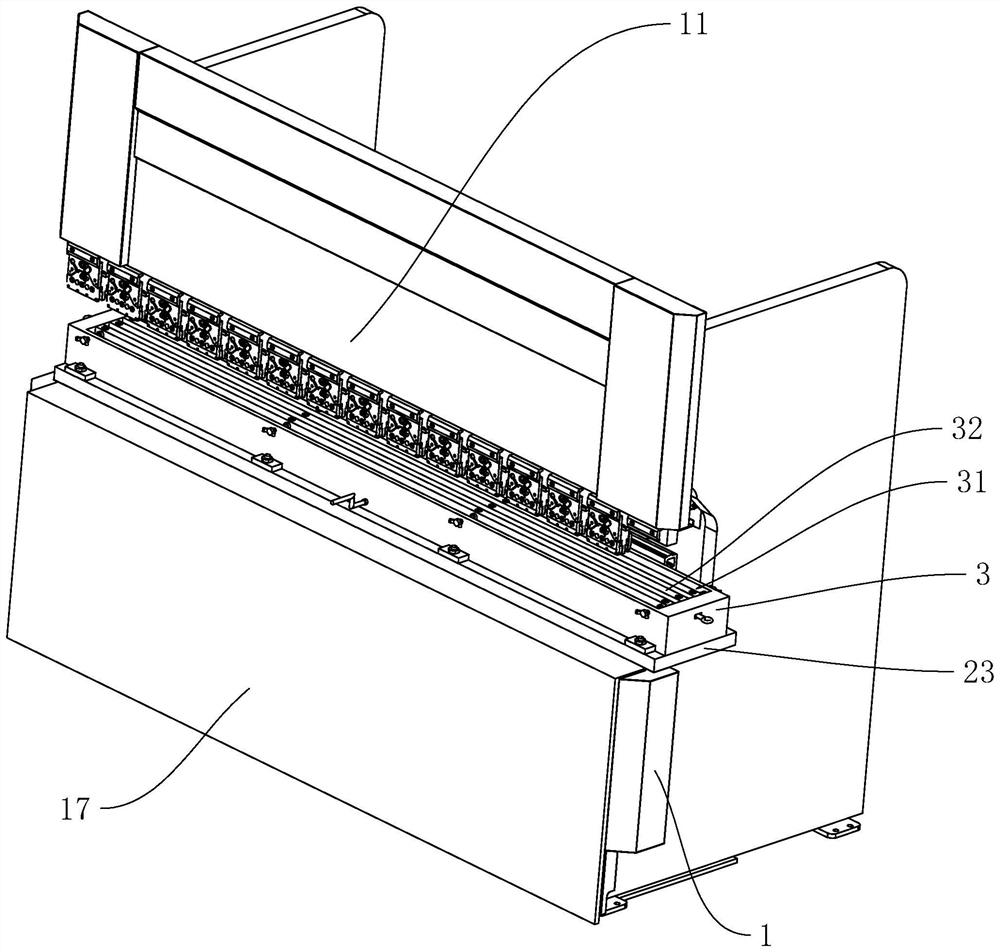

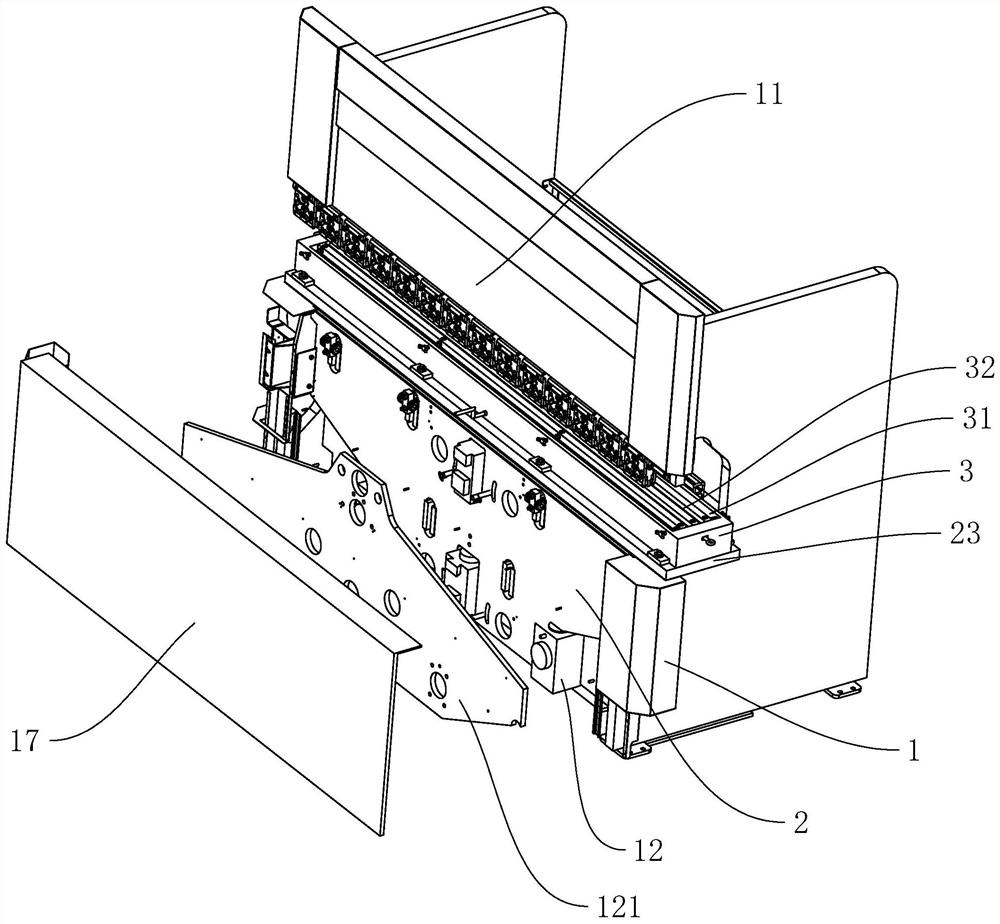

[0039] The embodiment of the present application discloses a bottom-moving bending machine. refer to figure 1 , figure 2 , the lower bending machine includes a frame 1, on which a bending upper mold 11 is fixedly installed, and the bending upper mold 11 is extended toward the ground, and slides on the frame 1 through a lifting mechanism A lifting slide 2 is connected, and a mold base 3 is fixedly installed on the lifting slide 2 through a locking assembly. A placement groove 31 is provided on the mold base 3, and a bending lower mold 32 is arranged in the placement groove 31. The bending lower The mold 32 is located directly below the bending upper mold 11, and the bending upper mold 11 and the bending lower mold 32 cooperate with each other to bend the steel plate.

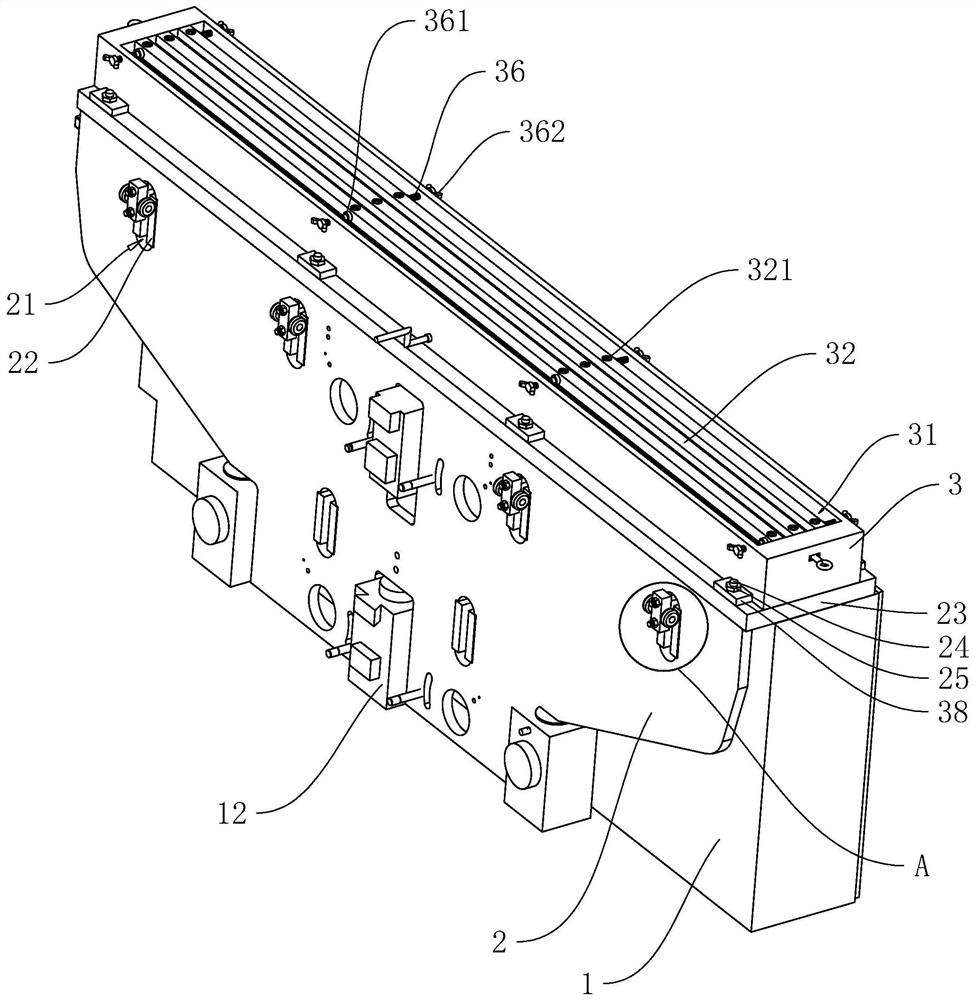

[0040] while referring to image 3 , Figure 4 , In this embodiment, the locking assembly includes a locking p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com