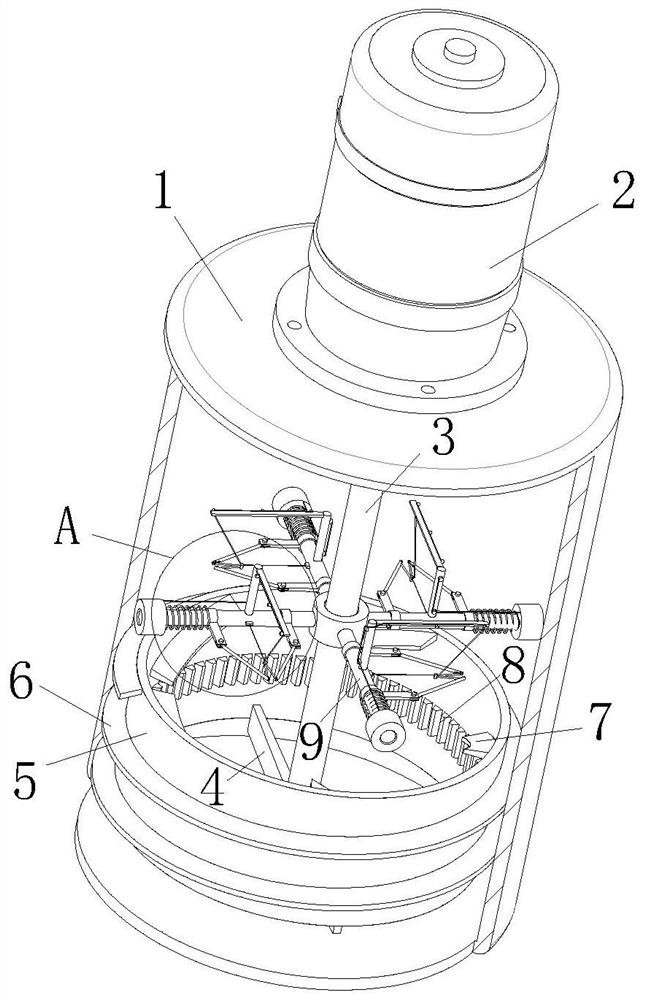

Reflective film UV production equipment

A technology for production equipment and reflective film, applied in the field of reflective film, can solve the problems of reducing the quality of water-based UV resin, unable to complete the stirring quickly, affecting the quality of reflective film, etc., to improve stirring efficiency, improve stirring efficiency and stirring quality, and speed up The effect of material exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

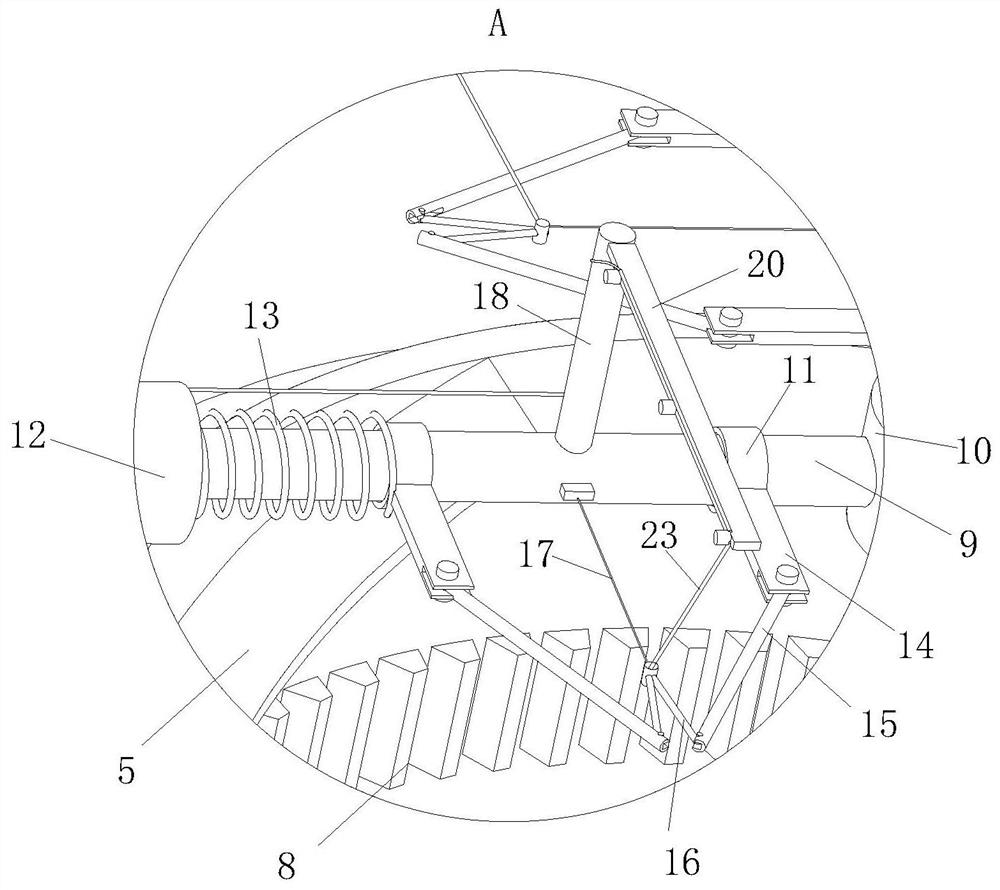

[0026] As an embodiment of the present invention, the support plate extends to the outside of the lower end of the inner tube 5 and contacts the bottom wall of the tank body 1 and is arranged obliquely. Through the setting of the support plate, on the one hand, the inner cylinder 5 can be connected and supported so that the inner cylinder 5 can rotate under the drive of the rotating shaft 3; Affect the uniformity of mixing.

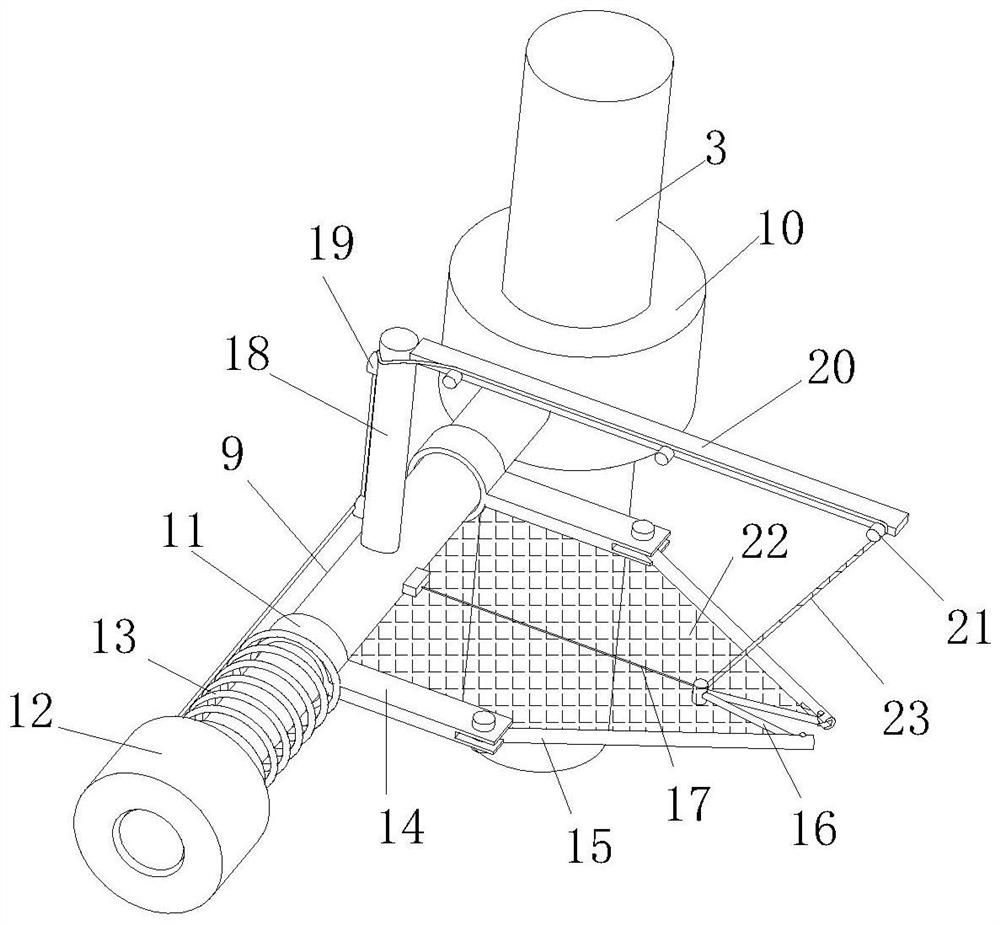

[0027] As an embodiment of the present invention, an adaptive stirring device is provided in the middle of the stirring rod 9, and the self-adapting stirring device includes two sets of second bushings 11 arranged on the stirring rod 9, the second bushings 11 is provided with a connecting rod 14 initially arranged horizontally, the free end of the connecting rod 14 is hinged with one end of the first swing rod 15, and the other end of the first swing rod 15 is hinged with a second swing rod 16, the Hinged between two groups of second fork 16 free ends an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com