Tire die pattern block assembling and correcting device

A tire mold and pattern block technology, applied in the field of tire manufacturing, can solve problems that affect stable use, influence, and reduce the accuracy of correction, and achieve the effects of improving applicability, avoiding elastic changes, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

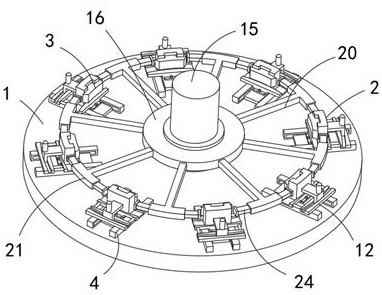

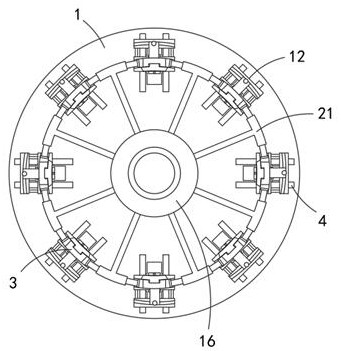

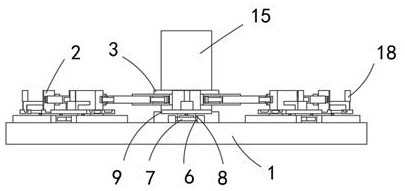

[0035]ReferenceFigure 1-8, A tire mold block assembly and correction device, comprising a base 1, an arcuate seat 2 and a block 3. The arcuate groove corresponding to the block 3 is opened on the side wall of the arcuate seat 2, and the block 3 is slidably connected to the arc In the groove, and the side wall of the block 3 is fixedly connected with a convex block that slides with the arc-shaped groove, the block 3 and the arcuate seat 2 are fixedly connected by a pin, and the pin is correspondingly arranged on the convex side wall of the block 3 Above, the stability of the connection between the block 3 and the arcuate seat 2 is ensured, and there is a gap between the block 3 and the arcuate seat 2, which can be fine-tuned.

[0036]Among them, the upper end of the base 1 is uniformly provided with multiple sets of mold components, and the number of multiple mold components can be set according to the needs of use. The mold components include two bar-shaped blocks 4 fixedly connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com