Automatic flaring device for round PVC pipes

An automatic and equipment technology, applied in the field of PVC round pipe automatic flaring equipment, can solve the problems of undiscovered reports, unguaranteed quality, low efficiency, etc., and achieve easy portability and disassembly, simple structure, and high flaring accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

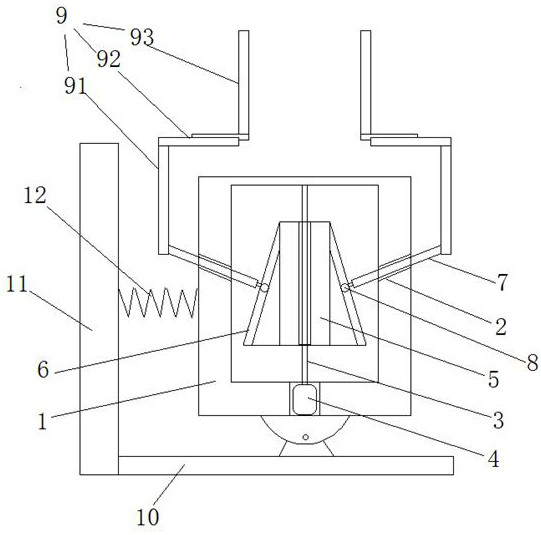

[0014] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] A PVC round pipe automatic flaring equipment, comprising a chassis 1 fixed on the ground, at least a pair of inclined holes 2 are opened on the side wall of the chassis 1, and the end of the inclined holes 2 located in the chassis 1 is lower than the end located outside the chassis 1 , the center of the cabinet 1 is provided with a screw mandrel 3 for limit rotation, the bottom of the screw mandrel 3 has a motor 4 to drive its rotation, the motor 4 is a stepping motor, and the screw mandrel 3 is provided with an internal thread sleeve 5, so A pair of chute 6 is provided on the outside of the internal thread sleeve 5, and the chute 6 is in an inclined state. One chute 6 corresponds to a slanted hole 2, and the chute 6 is perpendicular to the slanted hole 2, and the slanted hole 2 is provided with a telescopic Guide column 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com