Integrated multifunctional printing platform

A multi-functional, platform-based technology, applied in printing, printing devices, object separation, etc., can solve the problems of low pass rate and production efficiency, low degree of automation, and single function, so as to improve quality, enhance functionality, and reduce detection. workload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

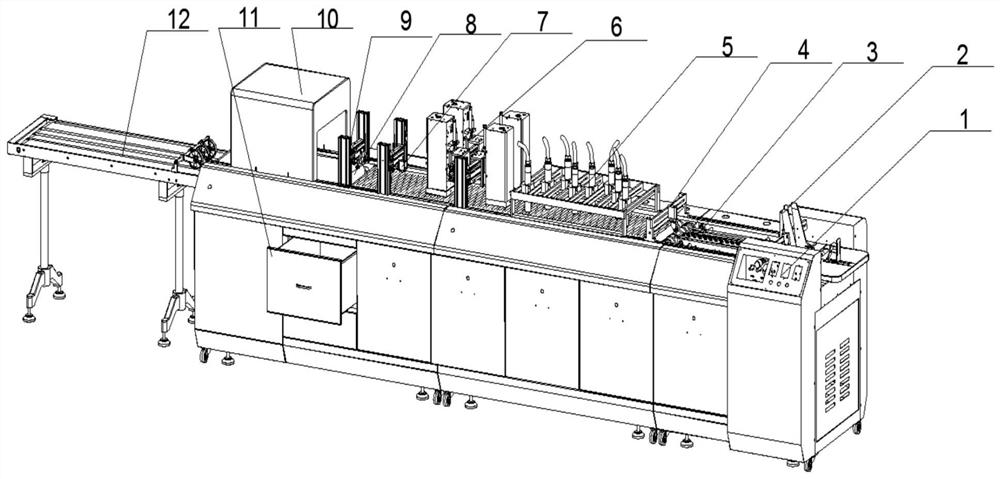

[0041] refer to figure 1 , an integrated multifunctional printing platform provided by the present invention includes a paper feeding platform, a coding platform, a conveying platform, a drying platform 10 and a material receiving platform 12 connected to the supporting base in sequence, and a control panel is also connected to the supporting base 1. The conveying platform includes a suction conveyor belt 8. A waste product removal device 9 is connected between the suction conveyor belt 8 and the drying platform 10. A high-speed linear camera 7 is connected to the side of the waste product removal device 9. The high-speed linear camera 7 and the waste product The rejecting device 9 is connected in communication.

[0042] When using the integrated multi-functional printing platform in this application to print products, firstly, the paper is automatically sorted, automatically corrected, and double-sheet detection is performed through the paper-feeding platform. Adjust, if there...

Embodiment 2

[0044] Based on Example 1, with reference to figure 1 , the paper feeding platform of this embodiment includes a sorter 2 , an automatic deviation corrector 3 and a double sheet detector 4 , and the sorter 2 , the automatic deviation corrector 3 and the double sheet detector 4 are all communicated with the control panel 1 .

[0045] The feeding and printing accuracy of the automatic deviation corrector 3 can be controlled within ±0.5mm to ensure the stability of the product. If the printing is a two-dimensional code, the readability of the two-dimensional code will be further improved.

[0046] The double-sheet detector 4 in the present application has the effect of preventing double-sheets, effectively avoiding missing printing and wrong printing. When there are double-sheets, you can choose to alarm and reject or automatically shut down.

Embodiment 3

[0048] Based on Example 2, refer to figure 1 , the pager 2 of this embodiment adopts a static friction automatic pager 2 .

[0049] The paging device 2 in this application is a friction type, bottom discharge, and 3 friction belts are used for paging, which can be compatible with products with a length of 60-400mm, a width of 30-400mm, and a weight of 80-400g / m2, and is suitable for expanding the paging of products made of various materials The scope of use of the entire equipment is improved; the static friction paging method is adopted to avoid damage to the product surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com