Anti-throwing-leakage gravel transport vehicle for civil construction

A technology of civil construction and transport vehicles, which is applied in the direction of goods transport vehicles, vehicles used for freight transportation, and transport objects, etc. It can solve the problems of easy rolling of gravel and easy rise of smoke and dust with the air flow, so as to avoid damage and noise pollution , Avoid throwing drips, good buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

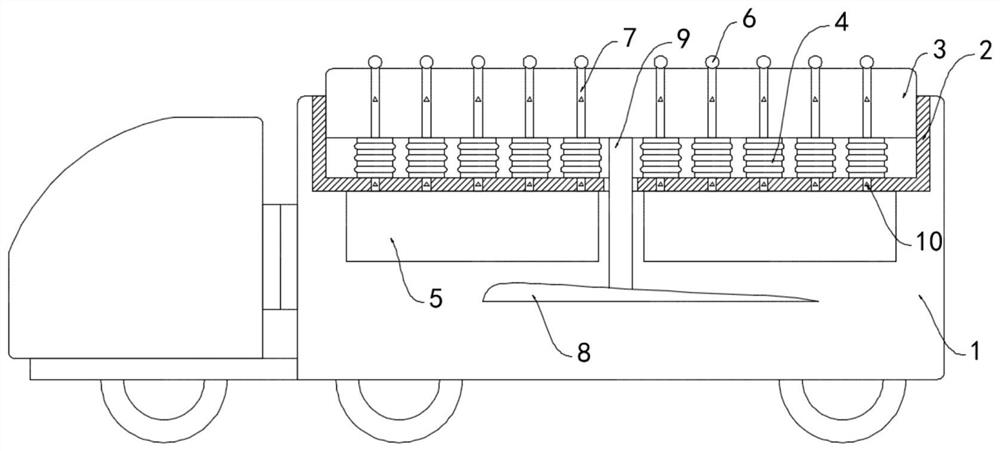

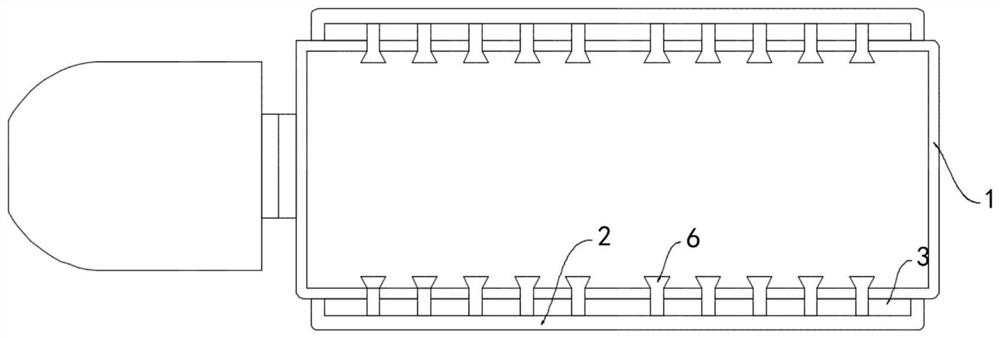

[0021] Such as Figure 1-2 As shown, a kind of anti-leakage gravel transport vehicle for civil construction construction, including a car body 1, is characterized in that, the side walls on both sides of the car body 1 are fixedly equipped with chute 2, and the chute 2 is slidingly connected with The baffle 3, the lower end of the baffle 3 is fixedly connected to the bottom of the chute 2 through a plurality of telescopic air bags 4, the lower surface of the chute 2 is fixedly installed with a water storage tank 5, and the water storage tank 5 is connected to the telescopic water tank 5 through a one-way water inlet pipe 10. The airbag 4 is connected, and the one-way water inlet pipe 10 only allows the water in the water storage tank 5 to enter the telescopic airbag 4. The telescopic airbag 4 is an elastic airbag made of rubber material, which can play a good buffering role and prevent the baffle 3 from going up and down. When reciprocating, it collides with the bottom surface...

Embodiment 2

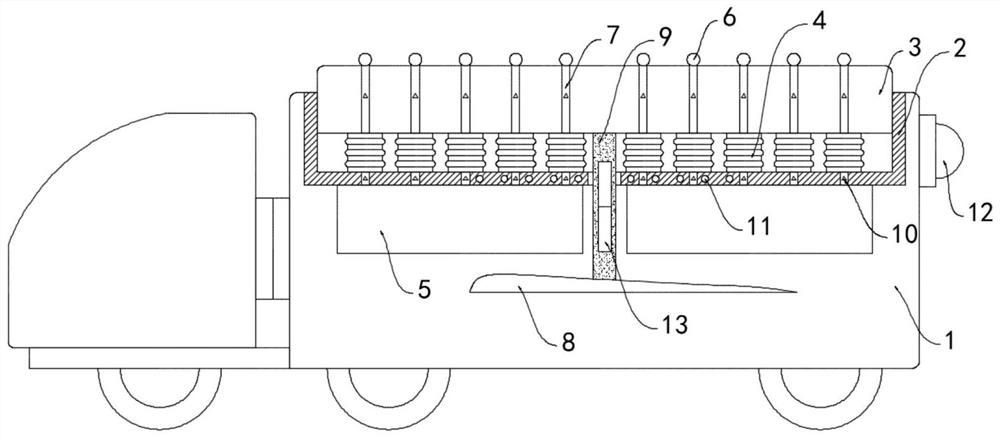

[0026] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that: a permanent magnet strip 13 is embedded in the slide bar 9, a plurality of closed coils 11 are embedded on the bottom side wall of the chute 2, and the windings of the closed coil 11 The setting direction is perpendicular to the direction of the magnetic field lines of the permanent magnetic strip 13, and a warning light 12 is installed on the side wall of the car body 1, and the positive and negative poles of the warning light 12 are respectively coupled and connected to the two ends of the closed coil 11.

[0027] In this embodiment, when the transport vehicle accelerates or decelerates, the probability of gravel falling out from the vehicle body 1 is relatively high. At this time, the air pressure effect on the wing plate 8 changes, driving the slide bar 9 to move upward or downward. , then the closed coil 11 cuts the magnetic field line of the permanent magnetic strip 13 to g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com