Water color paper with printing function and preparation method

A kind of watercolor paper and watercolor technology, applied in the direction of special paper, paper, papermaking, etc., can solve the problems that cannot meet the printing requirements, achieve the effect of expanding the use function and great application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0155] This embodiment provides a watercolor paper with a printing function, and the watercolor paper includes a coated paper layer and a watercolor paper layer.

[0156] The coated paper layer includes a coated base paper layer and a coating layer arranged on the coated base paper layer away from the watercolor paper layer;

[0157] The paper quantification of described watercolor paper is 300g / m 2 ; The watercolor paper layer is an all-cotton pulp watercolor paper layer; the side of the watercolor paper layer away from the coated paper layer is provided with blanket watercolor patterns; the quantification of the watercolor paper layer is 150g / m 2 ; The coated paper layer is a full wood pulp coated paper layer; the quantitative of the coated paper layer is 130g / m 2 ; The quality of the coating layer is 20g / m 2 .

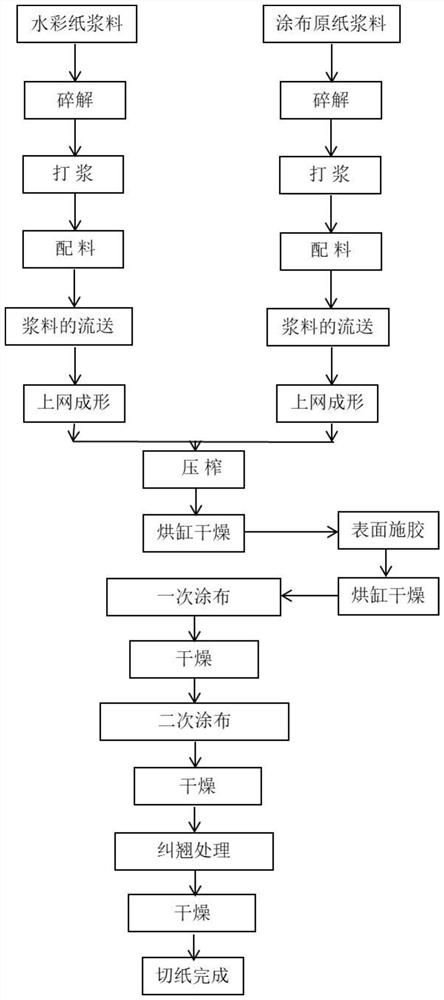

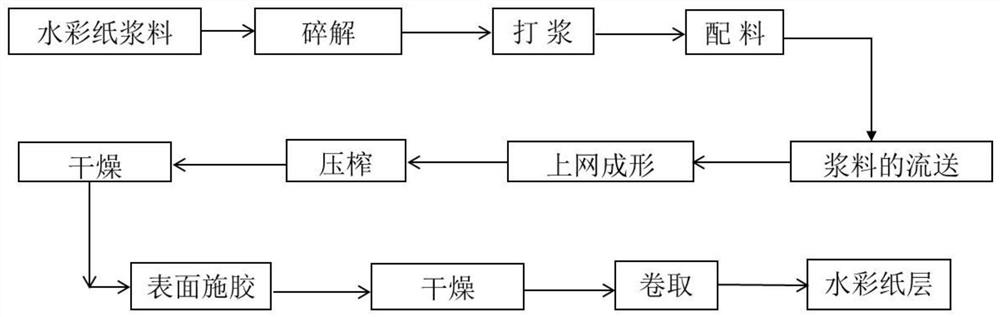

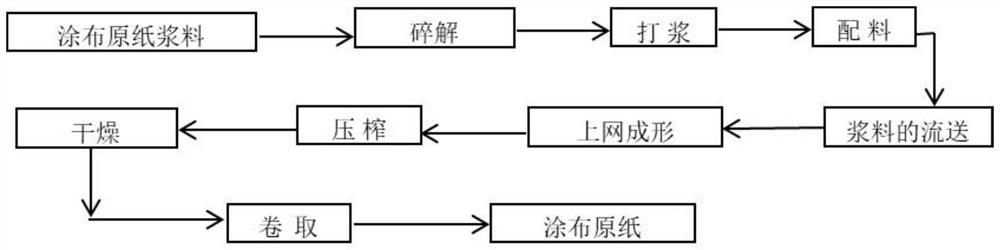

[0158] The preparation method of the watercolor paper with printing function provided by the present embodiment is as follows: figure 1 As shown, it specificall...

Embodiment 2

[0167] This embodiment provides a watercolor paper with a printing function, and the watercolor paper includes a coated paper layer and a watercolor paper layer.

[0168] The coated paper layer includes a coated base paper layer and a coating layer arranged on the coated base paper layer away from the watercolor paper layer;

[0169] The coated paper layer and the watercolor paper layer are compounded by glue.

[0170] The paper weight of the watercolor paper is 350g / m 2 ; The watercolor paper layer is a watercolor paper layer containing cotton pulp; the side of the watercolor paper layer away from the coated paper layer is provided with blanket watercolor patterns; the quantification of the watercolor paper layer is 170g / m 2 ; The coated paper layer is a full wood pulp coated paper layer; the quantitative of the coated paper layer is 140g / m 2 ; The quality of the coating layer is 30g / m 2 , the amount of glue is 10g / m 2 .

[0171] The preparation method of the watercolor ...

Embodiment 3

[0180] This embodiment provides a watercolor paper with a printing function, and the watercolor paper includes a coated paper layer and a watercolor paper layer.

[0181] The coated paper layer includes a coated base paper layer and a coating layer arranged on the coated base paper layer away from the watercolor paper layer;

[0182] The paper quantification of described watercolor paper is 150g / m 2 ; The watercolor paper layer is an all-wood pulp watercolor paper layer; the side of the watercolor paper layer away from the coated paper layer is provided with blanket watercolor patterns; the quantification of the watercolor paper layer is 75g / m 2 ; The coated paper layer is a full wood pulp coated paper layer; the quantitative of the coated paper layer is 55g / m 2 ; The quality of the coating layer is 20g / m 2 .

[0183] The preparation method of the watercolor paper with printing function provided by the present embodiment comprises the steps:

[0184] (1) The watercolor pap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Knocking degree | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com