A laminated floor, a curved side form for side molding, and a method for preparing a laminated floor

A technology for superimposing floors and floors, applied in floors, ceramic molding machines, molds, etc., can solve problems such as difficulty in ensuring reliability, structural integrity and seismic performance inspection of prefabricated floors, and large consumption of cast-in-place concrete floors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

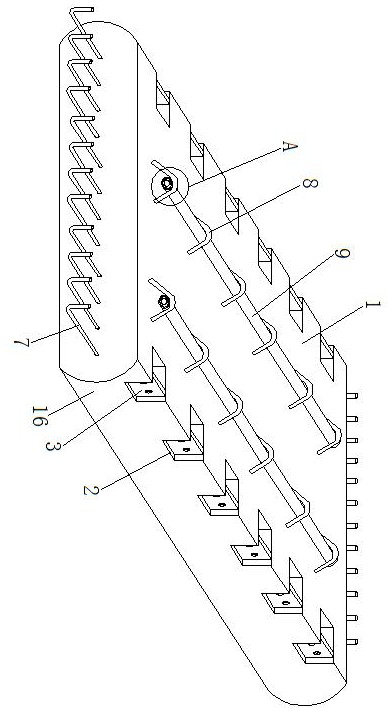

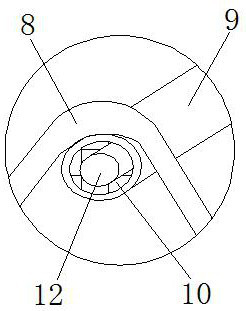

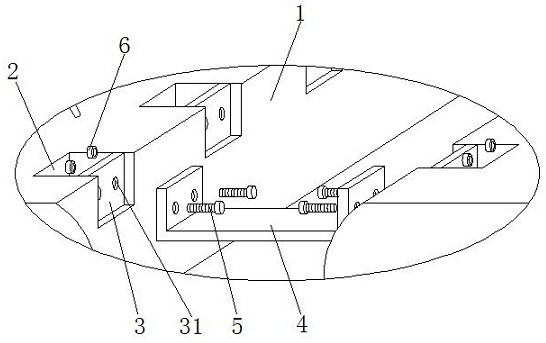

[0031] like Figure 1 to Figure 7The laminated floor slab shown includes a floor slab body 1 poured from reinforced concrete; the left and right sides of the floor slab body 1 are arc-shaped structures 16, and the upper part of the arc-shaped structure is provided with a plurality of pouring notches 2 at intervals. The left and right sides of the slab body are provided with arc-shaped structures, which can reduce the damage of the slab caused by collisions during re-transportation and ensure the quality of the slab; each pouring notch 2 is fixed with a positioning steel plate with an L-shaped structure on one side 3. The positioning steel plate 3 adjacent to the floor body 1 on the left and right is connected and fixed by the connecting steel plate 4 of U-shaped structure; the positioning steel plate 3 and the connecting steel plate 4 are fixedly connected by bolts 5 and nuts 6, and are arranged on the left and right sides of the floor body Pour the notch, and fix the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com