A wet dual-clutch automatic shifting system for oil drilling drawworks

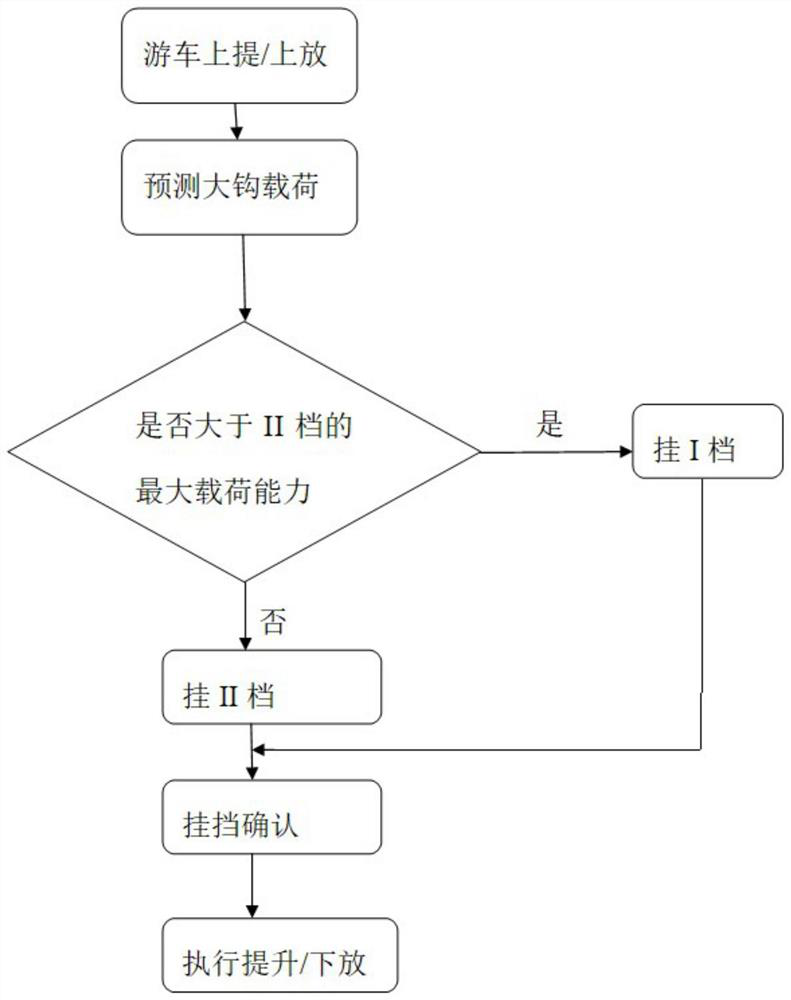

A wet dual-clutch, automatic gear shifting technology, applied in clutches, fluid drive clutches, non-mechanical drive clutches, etc., can solve the problems of difficult tooth alignment and high failure rate, and achieve the effect of automatic gear shifting with a success rate of shifting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

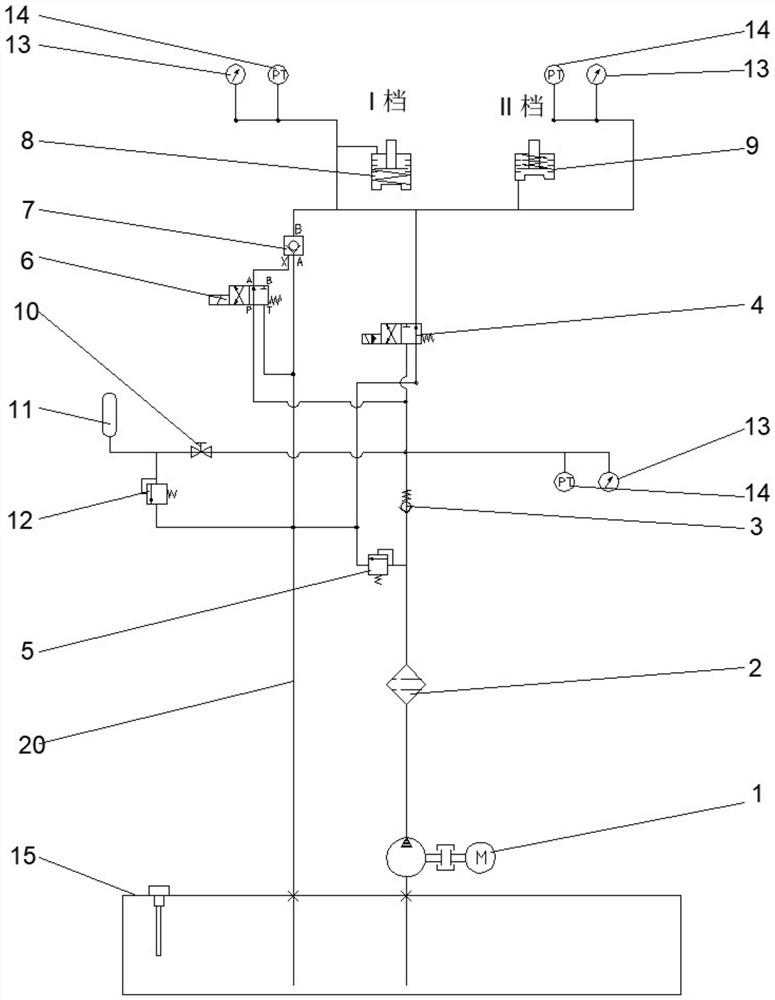

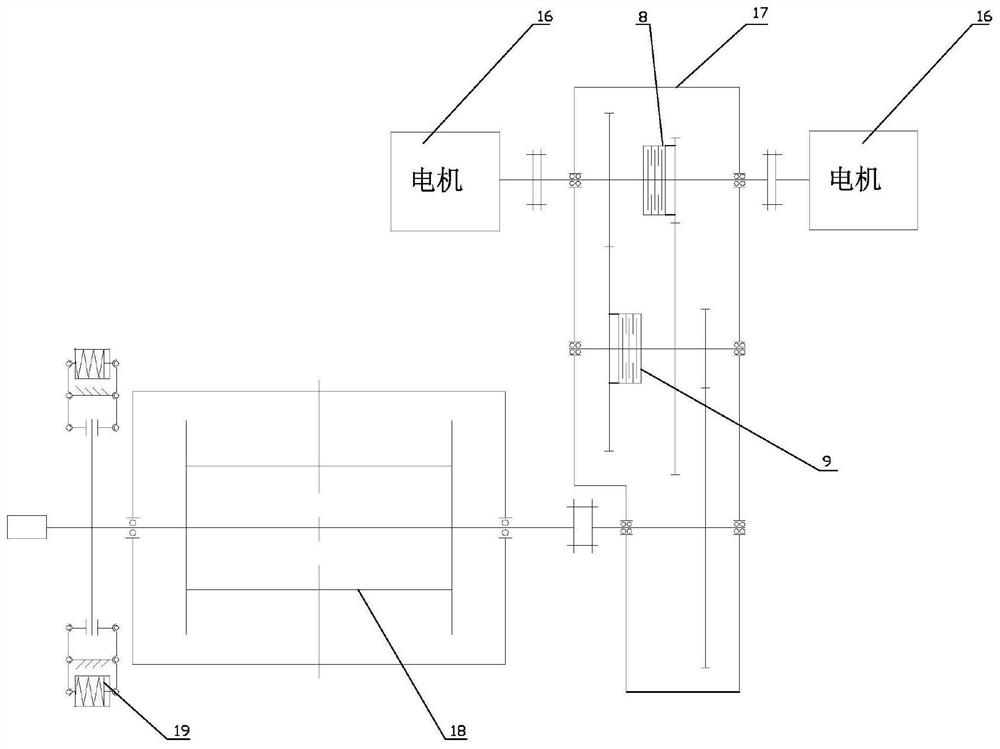

[0018] The present invention is a wet-type double-clutch automatic shifting system for an oil drilling drawworks, the structure of which is as follows: figure 1 As shown, it includes an oil tank 15. The oil tank 15 is connected to a hydraulic pump 1, a one-way valve 3, a two-position four-way solenoid valve a6, and a hydraulically controlled one-way valve 7. The hydraulically controlled one-way valve 7 is also connected through a pipeline. There are oil inlets for the I-gear clutch 8 and the II-gear clutch 9, the outlet of the one-way valve 3 is also connected to the two-position four-way solenoid valve 4 through the pipeline, and the two-position four-way solenoid valve 4 is connected to the I-gear clutch 8 through the pipeline. And the oil inlet of the second gear clutch 9, the oil tank 15 is also connected with an oil drain circuit 20, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com