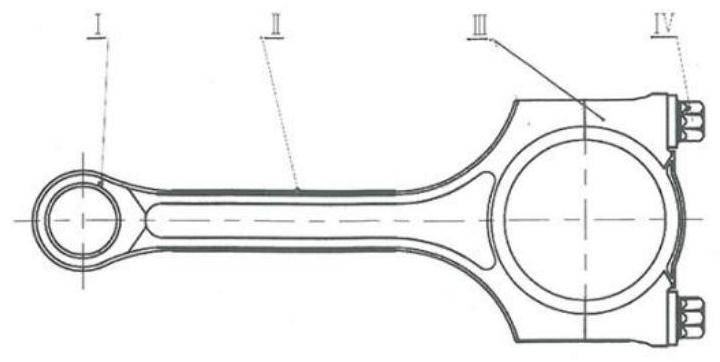

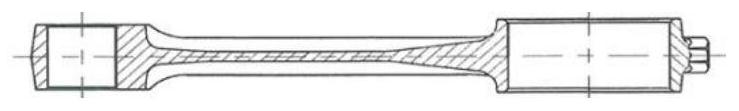

Inspection system for final moment of connecting rod assembly

A connecting rod assembly and torque technology, applied in the field of inspection tools for engine connecting rods, to improve inspection efficiency, eliminate inaccurate inspection data, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

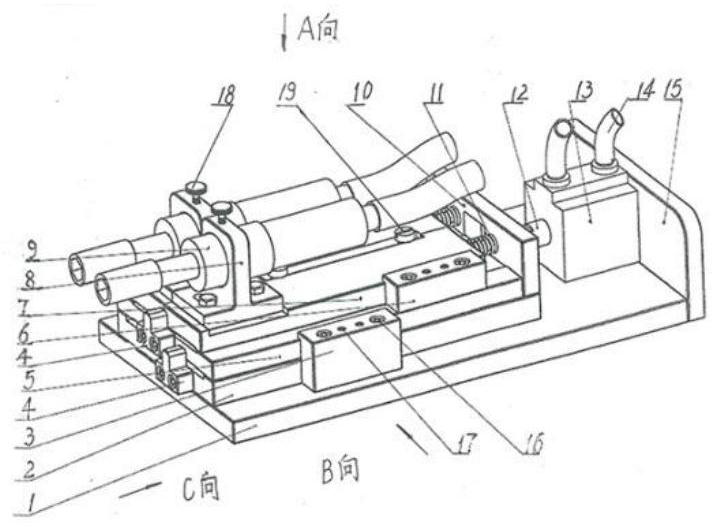

[0017] refer to image 3 , 4 , 5, explain the main technical solutions of the present invention: the present invention comprises base plate 1, fixed plate 2, first slidable groove plate 3, limit block 4, integral sliding plate 5, second slidable groove plate 6, sub-sliding plate 7 , Air gun holder 8, air gun 9, spring plate 10, spring 11, push-pull rod 12, cylinder 13, air pipe 14, backing plate 15, bolt 16, pin 17, stop screw 18, split screw 19, central control unit 20, displacement sensor 21, alarm 22, its specific structure:

[0018] a. On the upper plane of the bottom plate 1, install the fixed plate 2 through bolts 16 and pins 17. The left end of the fixed plate is equipped with a limit block 4, and the first slidable groove plate 3 is installed on the front and rear of the bottom plate 1 through bolts and pins (longitudinal ) on both sides of the fixed plate 2, an integral slide 5 is installed, and the left end of the integral slide 5 is equipped with a limit block 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com