Method for testing color fastness to benzoyl peroxide of textiles

A technology of benzoyl peroxide color and test method, which is applied in the field of textiles, can solve the problems of affecting appearance, textile fading, dye fading, etc., and achieve the effect that the testing process is simple and easy to understand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0045] 1. Take two ten square centimeter samples (blue woven fabric), one as a control sample and the other as a test sample. Samples taken shall include all pattern colors. If possible, the pattern color of the control sample should be consistent with that of the test sample;

[0046] 2. Before the sample test, it needs to be washed once according to the washing mark (ISO 6330 4M procedure, low temperature drying) to remove the finishing agent on the sample;

[0047] 3. Humidify the test sample for at least four hours in an environment with a relative humidity of 65±4% and a temperature of 20±2°C;

[0048] 4. Apply 1 gram of the test reagent (a reagent whose main activity is 10% benzoyl peroxide, Oxy-10) to the sample with a spatula within a radius of 2 cm. All colors are to be tested;

[0049] 5. Start timing after the reagent is applied to all samples, place the samples flat in a dark room with ventilation and light, and the test time is 4 hours;

[0050]6. When the tes...

no. 2 example

[0054] 1. Take two ten square centimeter samples (pink jersey fabric), one as a control sample and the other as a test sample. Samples taken shall include all pattern colors. If possible, the pattern color of the control sample should be consistent with that of the test sample;

[0055] 2. Before the test, the sample should be washed once according to the washing mark (AATCC TM 135, 30°C Normal washing program, low temperature drying) to remove the finishing agent on the sample;

[0056] 3. Humidify the test sample for at least four hours in an environment with a relative humidity of 65±4% and a temperature of 20±2°C;

[0057] 4. Apply 1 gram of the test reagent (a reagent whose main activity is 10% benzoyl peroxide, Oxy-10) to the sample with a spatula within a radius of 2 cm. All colors are to be tested;

[0058] 5. Start timing after the reagent is applied to all samples, place the samples flat in a dark room with ventilation and light, and the test time is 6 hours;

[...

no. 3 example

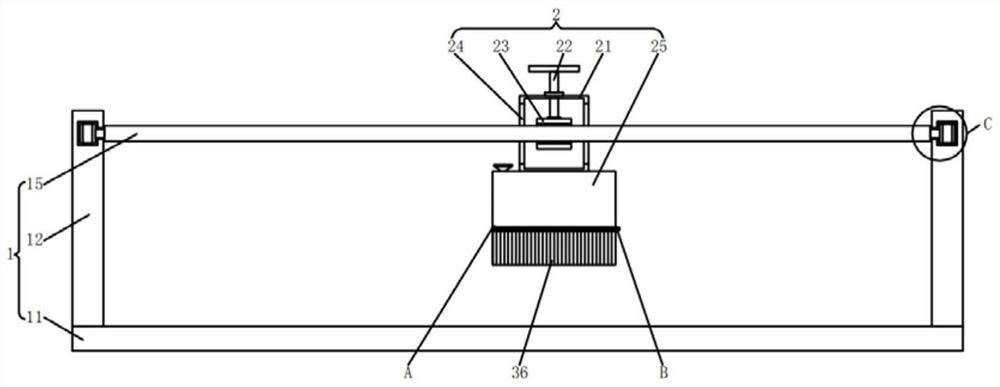

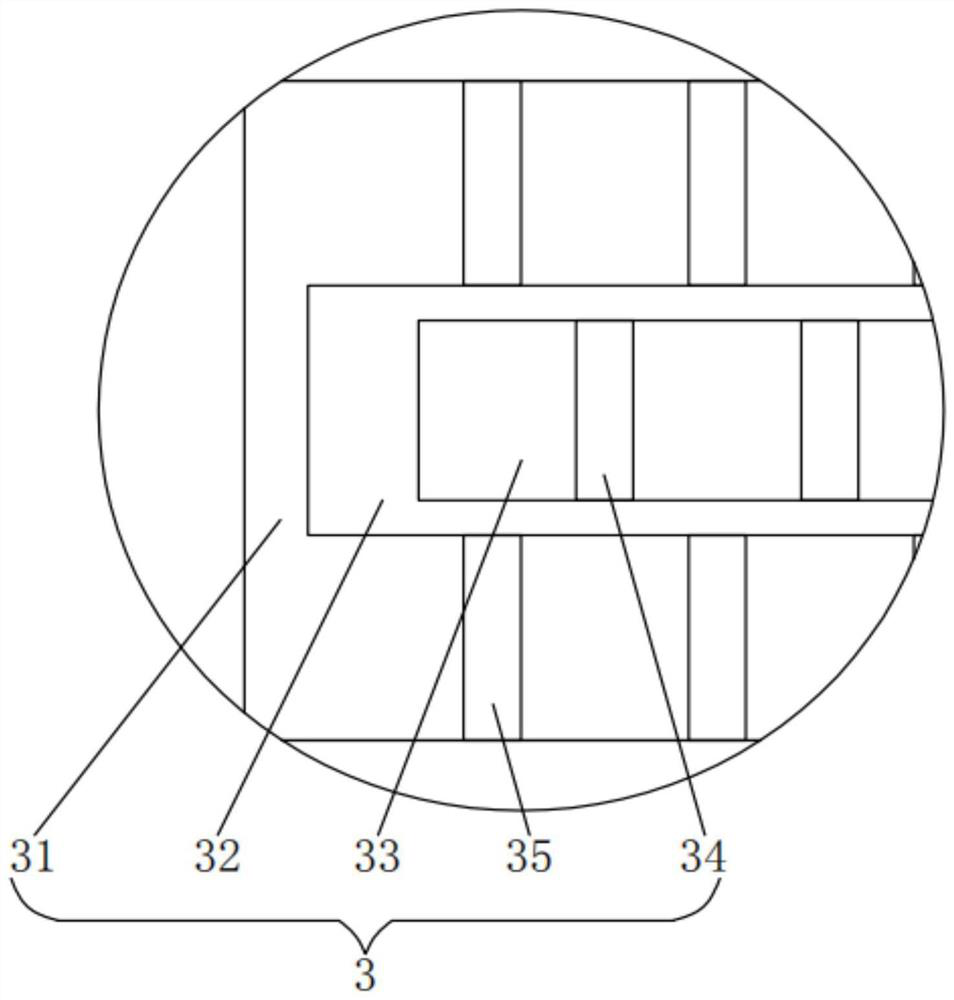

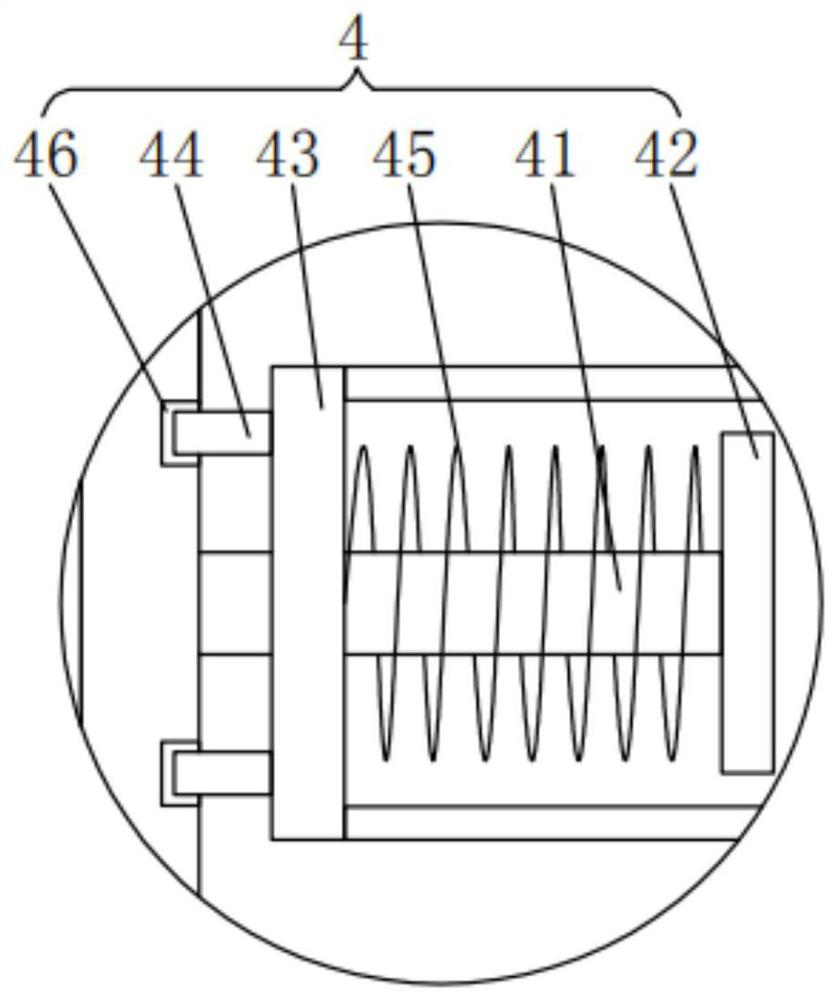

[0063] see Figure 1-4 , based on the test method for the color fastness of textiles to benzoyl peroxide provided in the first embodiment of the application, the third embodiment of the application proposes another test for the color fastness of textiles to benzoyl peroxide method. The third embodiment is only a preferred mode of the first embodiment, and the implementation of the third embodiment will not affect the independent implementation of the first embodiment.

[0064] Concrete, the difference of the test method of the textiles resistance to benzoyl peroxide color fastness that the third embodiment of the application provides is that the test method of textiles resistance to benzoyl peroxide color fastness also includes the test method for S5 Reagent smearing device 1 in the step, described smearing device 1 comprises substrate 11, and fixed plate 12 is fixedly connected on described substrate 11, and the inside of described fixed plate 12 is provided with sliding gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com