Optimal design method of passenger car thin-walled beam

An optimized design, thin-walled beam technology, applied in the automotive field, can solve problems such as incomplete energy absorption of thin-walled beams, and achieve the effect of improving collision safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be clearly and completely described below in conjunction with the drawings and tables, but this embodiment should not be construed as limiting the present invention.

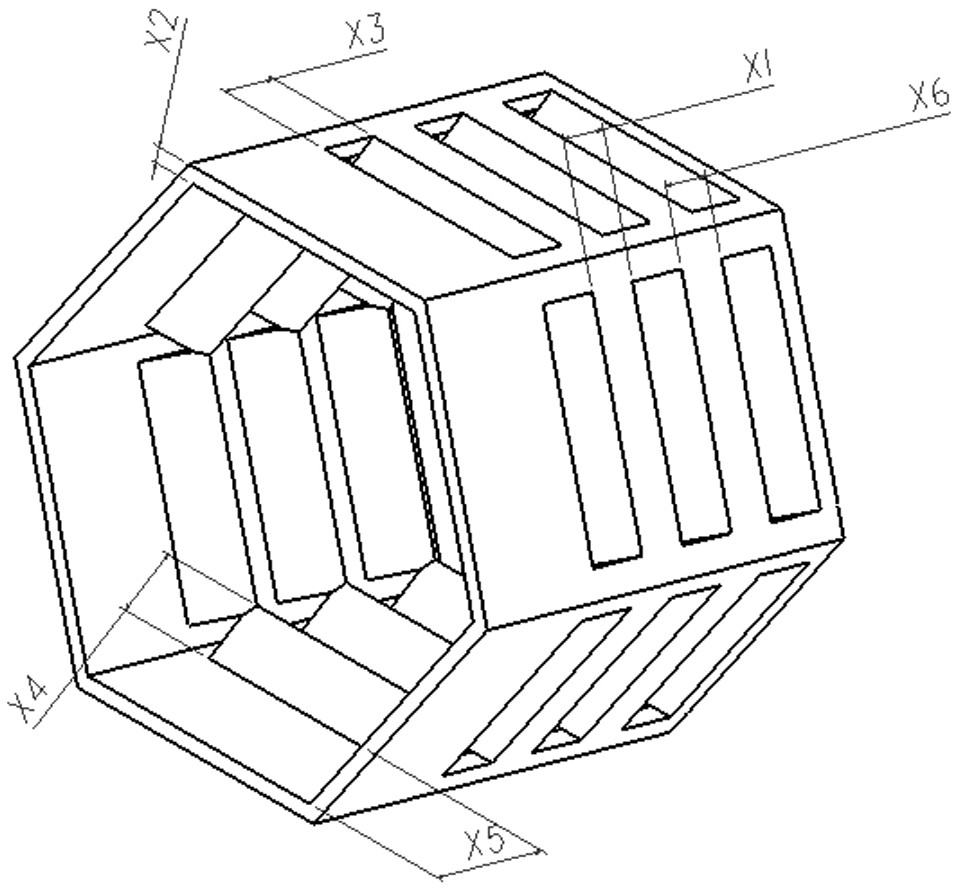

[0033] The present invention as Figure 1 to Figure 9 Shown:

[0034] An optimal design method for thin-walled passenger car beams, the specific steps are:

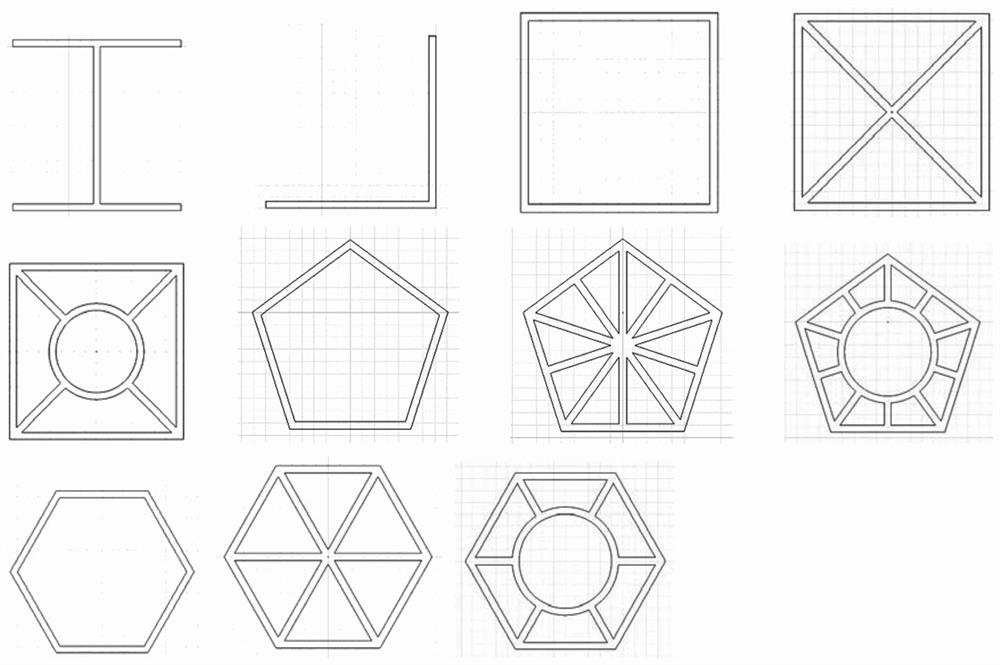

[0035] S1. Establish three-dimensional models of thin-walled beams with different cross-sections ( figure 1 As shown), when modeling, the cross-sectional area of thin-walled beams of different shapes is controlled to be the same, and a finite element model is established according to the three-dimensional model;

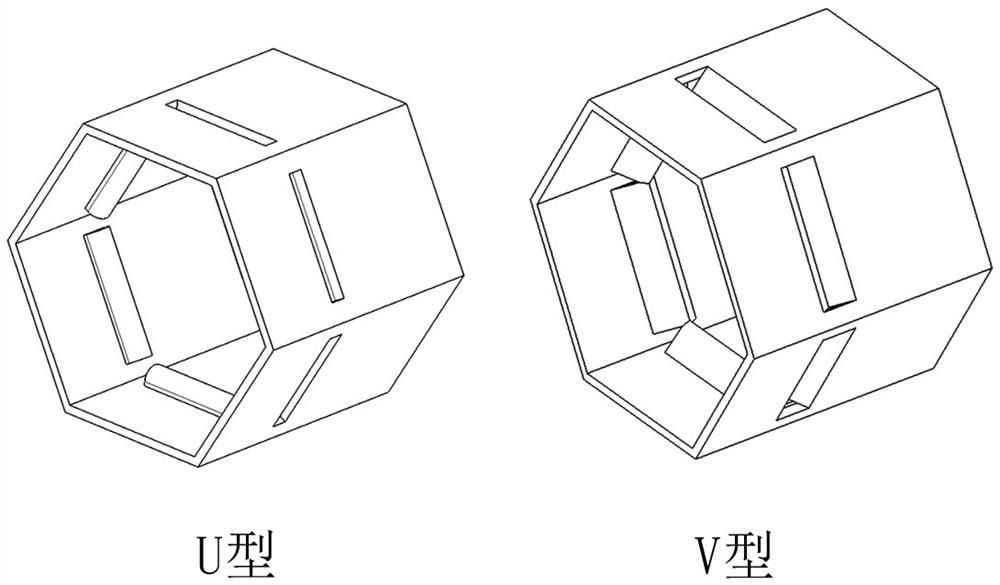

[0036] S2. Under the same three collision conditions of material, initial collision velocity, and end-applied mass, conduct collision simulation on different thin-walled beam finite element models, and select the thin-walled beam with the best cross-section based on the principles of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com