Neural network laser cutting quality prediction method

A laser cutting, neural network technology, applied in neural learning methods, biological neural network models, design optimization/simulation, etc., can solve the problems of long cycle, high cost, waste of efficiency, etc., and achieve the effect of short cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

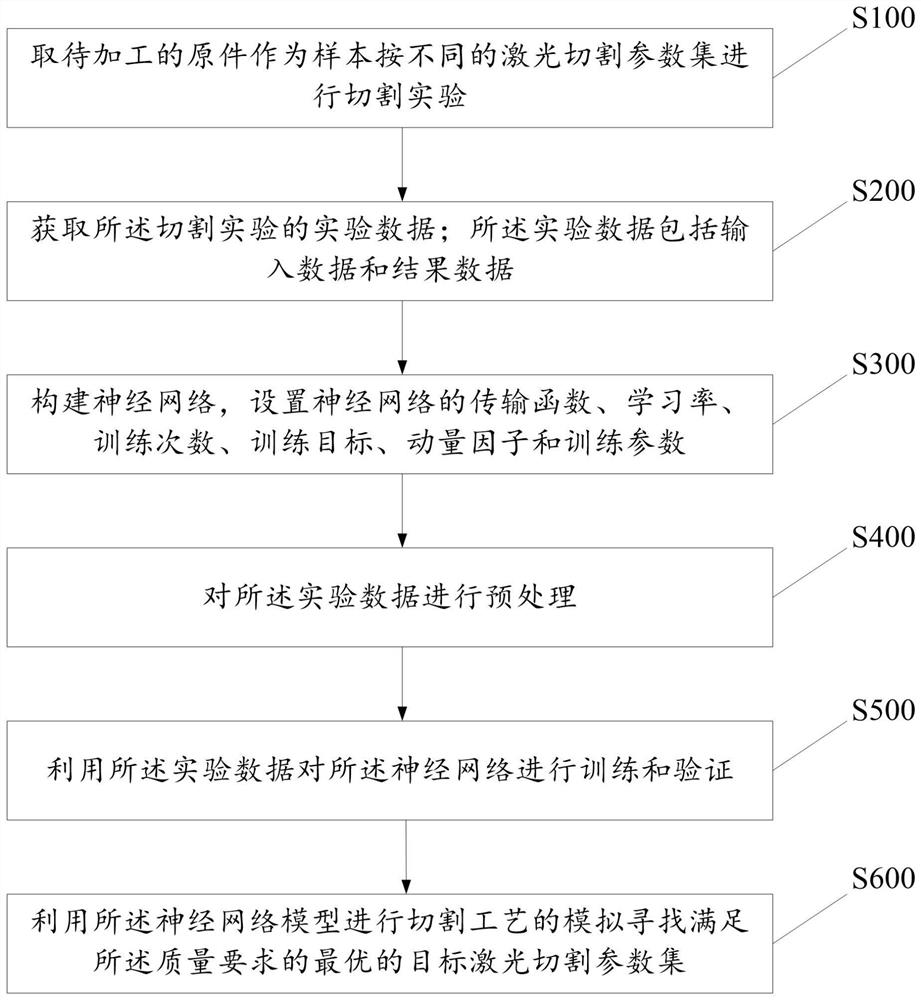

[0028] refer to figure 1 Shown, the present invention provides a kind of neural network laser cutting quality prediction method, comprises the following steps:

[0029] S100, taking the original to be processed as a sample and performing cutting experiments according to different laser cutting parameter sets;

[0030] Specifically, randomly select a certain number of the originals, set the laser cutting parameter set, and the parameter X in the laser cutting parameter set i Including the power of laser cutting equipment, the blowing speed of laser cutting equipment, the focal length setting of laser cutting equipment and the cutting speed of laser cutting equipment, etc., which are set according to the specific processing originals. Carrying out N repeated cutting on the surface to be processed of the original to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com