A three-channel molten salt reactor core structure and three-channel molten salt reactor system

A core structure and a molten salt reactor technology are applied in the field of a three-flow molten salt reactor core structure and a three-flow molten salt reactor system, and can solve the problems of low operating cost, high outlet temperature of liquid fuel molten salt thermal reactor, long service life, etc. problems, to achieve the effect of long core life, meet the needs of nuclear non-proliferation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

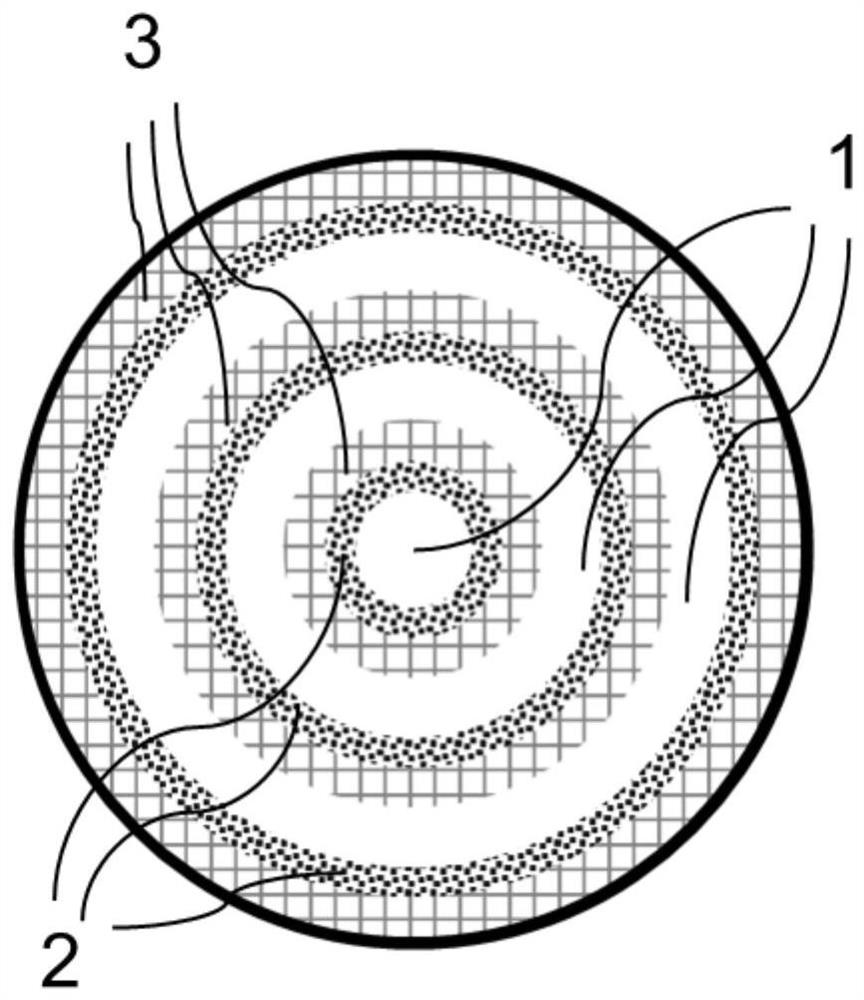

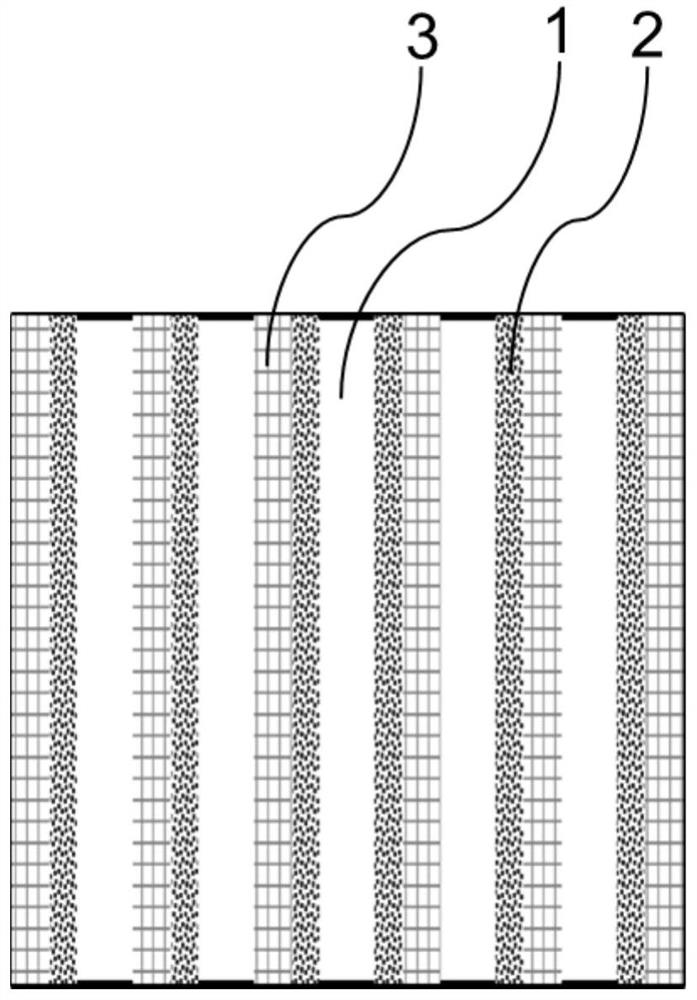

[0067] like figure 1 and figure 2 As shown, in the three-channel molten salt reactor core structure of Embodiment 1, it includes a fuel flow channel 1, a moderating flow channel 2 and a cooling flow channel 3; the fuel flow channel 1 is used for accommodating fuel salt, and the cooling flow channel 3 is used for In order to accommodate the coolant, the moderator flow channel 2 is used to accommodate the moderator; wherein, the fuel flow channel 1, the moderator flow channel 2 and the cooling flow channel 3 are not communicated with each other, and the axes are parallel to each other; the fuel flow channel 1 is embedded in the It is sleeved in the moderating flow channel 2 , and the moderating flow channel 2 is nested in the cooling flow channel 3 .

[0068] The axes of the fuel flow channel 1 , the moderating flow channel 2 and the cooling flow channel 3 are coincident. The axial cross-sections of the fuel flow channel 1 , the moderating flow channel 2 and the cooling flow ...

Embodiment 2

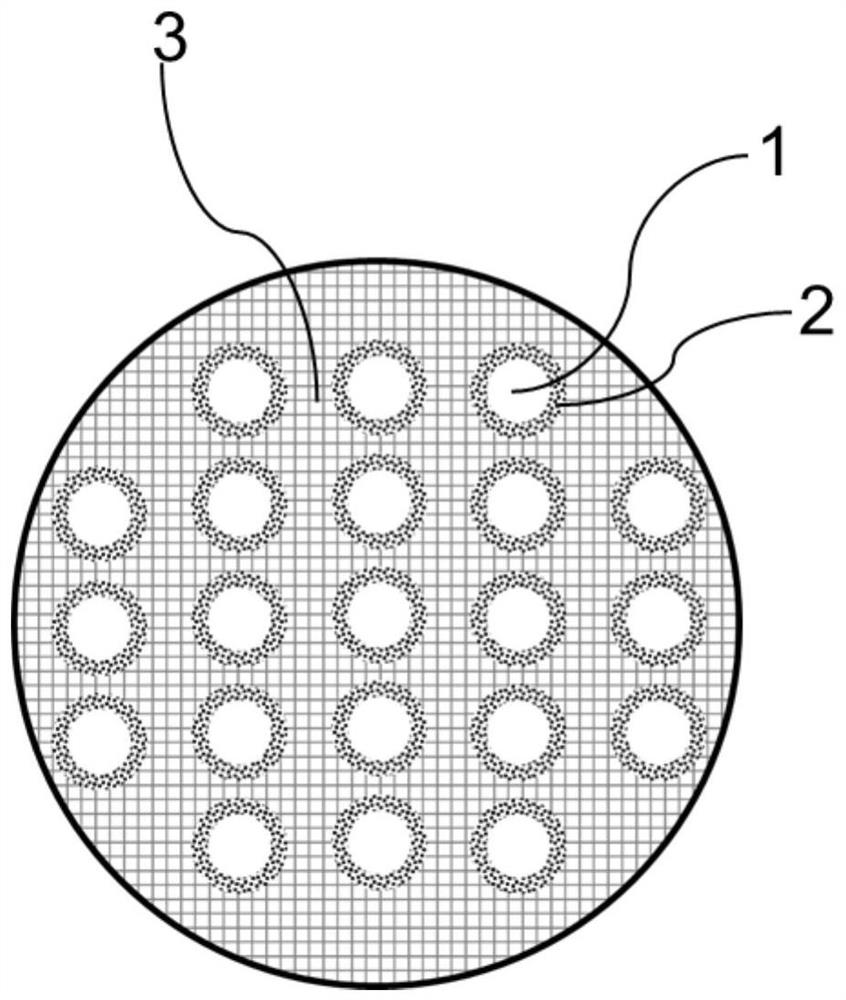

[0079] like image 3 and Figure 4 As shown, in the three-channel molten salt reactor core structure of Embodiment 2, it includes a fuel flow channel 1, a moderating flow channel 2 and a cooling flow channel 3; the fuel flow channel 1 is used to accommodate the fuel salt, and the cooling flow channel 3 is used for In order to accommodate the coolant, the moderator flow channel 2 is used to accommodate the moderator; wherein, the fuel flow channel 1, the moderator flow channel 2 and the cooling flow channel 3 are not communicated with each other, and the axes are parallel to each other; the fuel flow channel 1 is embedded in the It is sleeved in the moderating flow channel 2 , and the moderating flow channel 2 is nested in the cooling flow channel 3 .

[0080] The axes of the fuel flow channel 1 and the moderation flow channel 2 are coincident, and the axial cross-sections of the moderation flow channel 2 and the fuel flow channel 1 are concentric circles. There are 112 moder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com