Gadolinium-loaded fuel rods, fuel assemblies with gadolinium-loaded fuel rods, and pressurized water reactor core

A fuel assembly and fuel rod technology, applied in the field of nuclear reactors, can solve the problems of low enrichment, difficulty in realizing the direct application of recycled uranium fuel, expensive maintenance costs, etc., so as to save uranium resources, save the cost of combustible poisons, and meet the requirements of the reactor. The effect of core safety requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]Gadolinium loaded fuel rods comprising fuel cores made of recycled uranium oxide and Gd 2 o 3 constituted, the Gd 2 o 3 The mass fraction of recovered uranium oxide is 3%~5%, and the mass fraction of recovered uranium oxide is 95%~97%. 235 The U enrichment degree does not exceed 1.5%.

[0035] Recycled Uranium (RU) is manufactured using spent fuel produced in the nuclear power production of light water reactors (LWR). The uranium separated from spent fuel after chemical reprocessing is called reprocessed or recycled uranium in the industry. Recovered uranium (RU) differs from natural uranium (NU), which contains only three isotopes 234 U 235 U and 238 U. While RU obtained after irradiation and cooling in LWR has different isotopes from natural uranium, specifically, RU includes four additional uranium isotopes not present in natural uranium 236 U 232 U 233 U and 237 U, ie RU including isotopes 234 U 235 U 238 U 236 U 232 U 233 U and 237 U. Recovery of ...

Embodiment 2

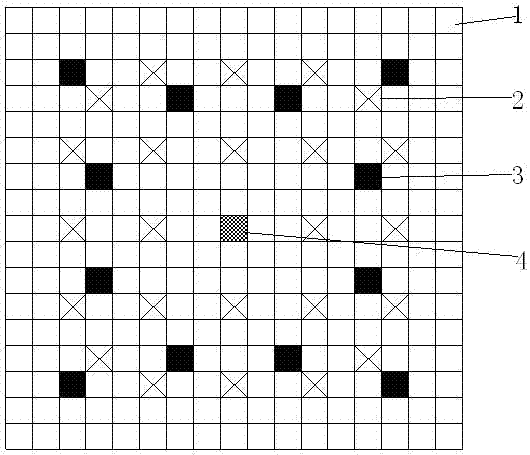

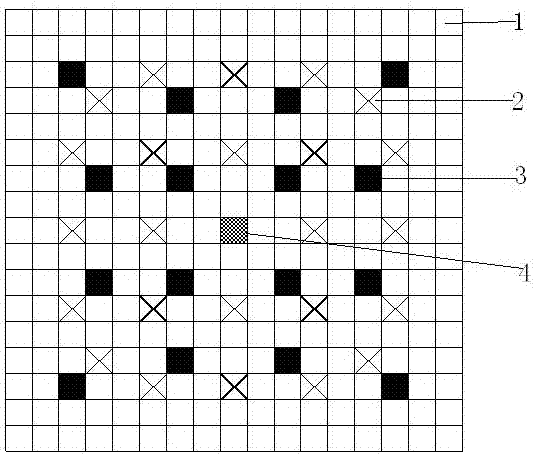

[0039] In this embodiment, the fuel assembly with gadolinium-loaded fuel rods includes fuel rods, guide pipes 2, and instrumentation pipes 4. The fuel rods include gadolinium-free fuel rods 1 and recycled uranium-loaded gadolinium fuel rods 3. The recycled uranium The gadolinium-loaded fuel rods 3 are the gadolinium-loaded fuel rods using recycled uranium in Example 1, and the number of the recycled uranium-loaded gadolinium fuel rods 3 is 8, 12, 16, 20 or 24.

[0040] The fuel assembly in this embodiment is used in the core of a pressurized water reactor nuclear power plant.

[0041] The guide tube 2, instrument tube 4, gadolinium-free fuel rods 1 and recycled uranium-loaded gadolinium fuel rods 3 are arranged in a square grid in a square structure:

[0042] The instrumentation tube 4 is arranged in the center of the fuel assembly;

[0043] The guide tubes 2 are arranged in at least two circles around the instrument tube 4 to form at least two guide tube rings, and the adjac...

Embodiment 3

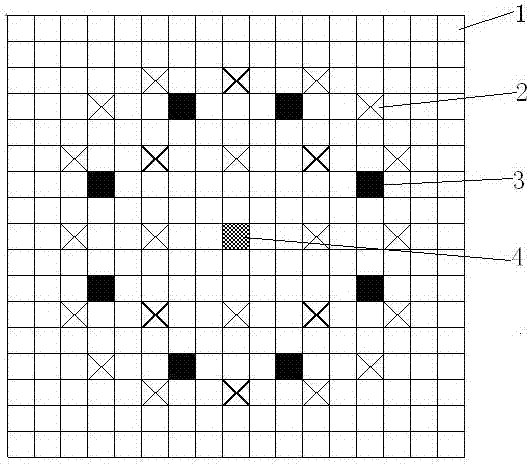

[0051] On the basis of Embodiment 2, this embodiment provides a specific structure of a fuel assembly in which the number of recycled uranium-loaded gadolinium fuel rods 3 is eight.

[0052] Such as figure 1 As shown, the fuel assembly includes 8 recycled uranium-loaded gadolinium fuel rods 3, 24 guide tubes 2, 1 instrument tube 4, 256 gadolinium-free fuel rods 1, 256 gadolinium-free fuel rods 1, 8 recycled uranium Gadolinium-loaded fuel rods 3, guide tubes 2, and instrument tubes 4 are arranged in a square of 17×17, that is, arranged in 17 rows and 17 columns:

[0053] The instrumentation tube 4 is arranged in the center of the fuel assembly;

[0054] The 24 guide pipes 2 are arranged in two circles of guide pipe rings centered on the instrument pipe 4: the inner ring and the outer ring. The inner ring is located on a 7×7 rectangular ring centered on the instrument pipe 4. 8 guide tubes 2; the outer ring is in a circular or rectangular ring shape, 16 guide tubes 2 are rough...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com