An online non-stop operation robot

An operating robot and robot technology, applied in the installation of overhead lines/cable equipment, electrical components, cables, etc., can solve problems such as low work efficiency, potential safety hazards, long working hours, etc., and achieve high work efficiency, enhanced applicability, The effect of improving satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

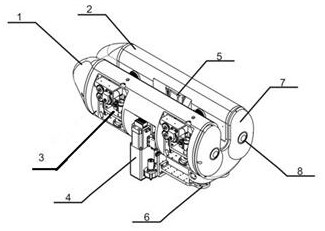

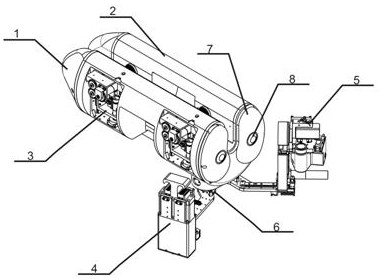

[0019] Such as Figure 1-2 As shown, an online non-stop operation robot includes: a robot tail assembly 1, a robot body 2, a wire holding device 3, a wire clamp installation tool 4, a peeling operation tool 5, a flexible rotary platform 6, a robot decoration cover 7, High-definition zoom camera 8; the robot tail assembly 1 is installed at the end of the robot body 2, and the wire holding device 3 is installed in pairs on one side of the robot body 2, and two flexible rotary platforms 6 are located below the head end of the robot body 2, and With respect to the symmetrical distribution of the axis of the robot body 2, the wire clamp installation tool 4 and the peeling operation tool 5 are respectively located on both sides of the robot body 2, and are connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com