Spiral pipe type air atomizing nozzle

A technology of air atomization and spiral tube, applied in the direction of injection device, liquid injection device, etc., can solve the problem of insufficient fuel atomization, achieve the effect of enhancing atomization effect, improving uniformity and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described now in conjunction with accompanying drawing:

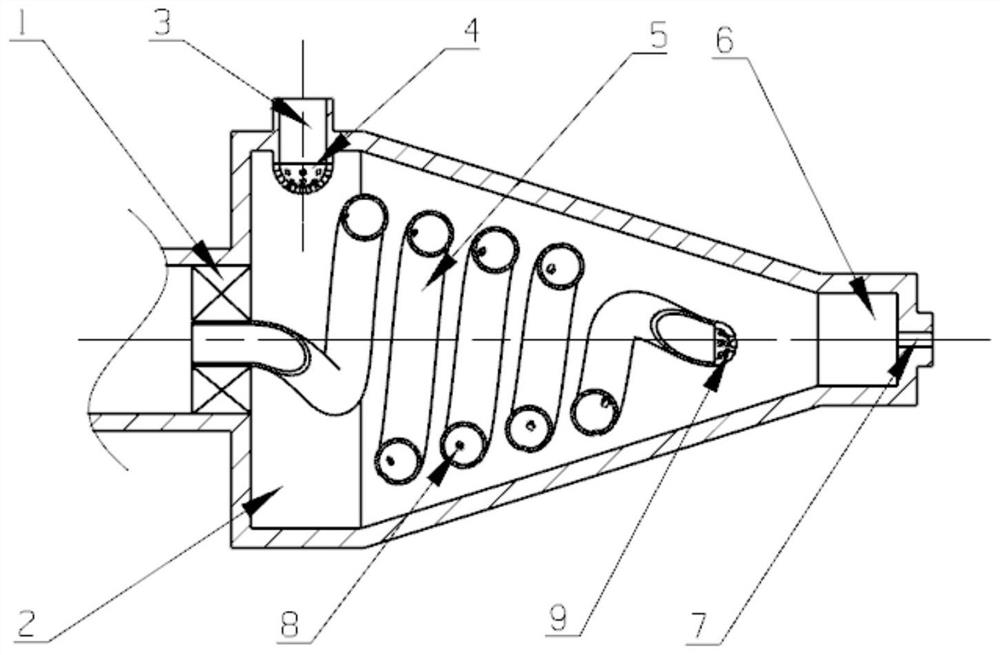

[0025] combine figure 1 , The invention provides a helical tube air atomizing nozzle which can effectively improve the atomization effect of liquid fuel and reduce pollution discharge.

[0026] Specific process:

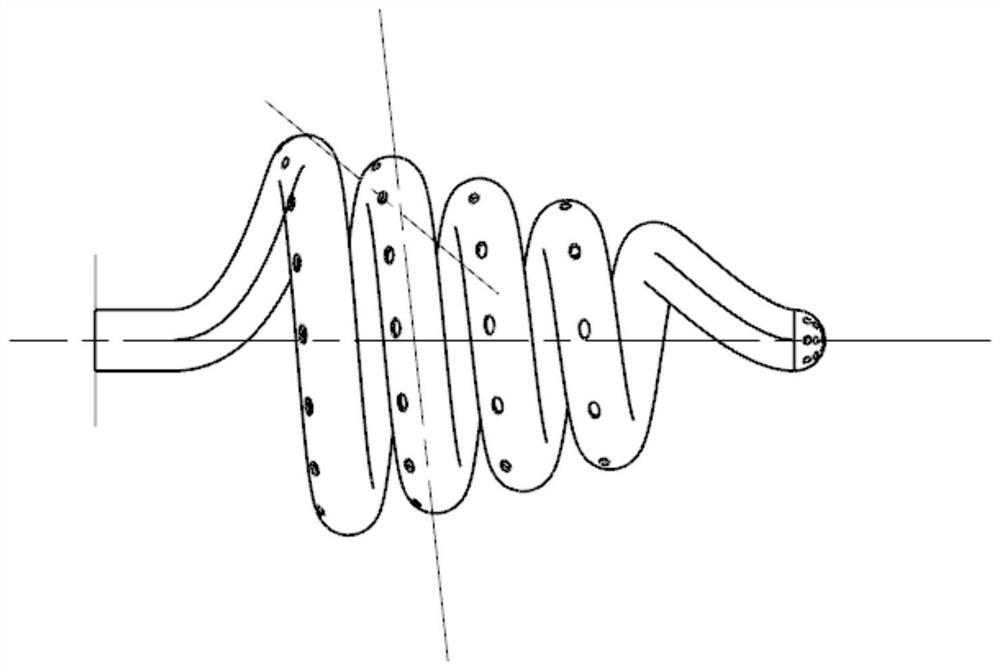

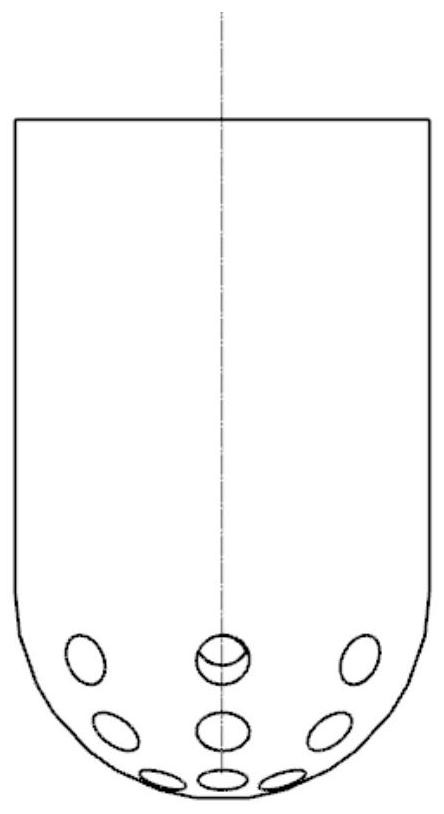

[0027] The gas enters from the nozzle head, part of it passes through the axial swirler 1 to form an outer ring airflow, and the other part enters the spiral tube 5 to form an inner ring airflow. The outer ring airflow forms a high-speed rotating turbulent flow in the inner chamber 2 . The inner ring airflow accelerates and rotates in the spiral tube 5 and flows downstream. The central axis of the inclined hole 8 has a certain distance from the central axis of the spiral pipe at the position, and the pipe body is in a spiral shape, so that the airflow ejected through the inclined hole 8 generates Circumferential velocity; the angle between the central axis of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com