Pressing equipment for assembly

A technology of pressing equipment and hydraulic mechanism, which is applied in the field of stamping, can solve problems such as loud noise, replacement of mold templates, and large vibration, and achieve the effects of reducing pressure, increasing force-bearing area, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

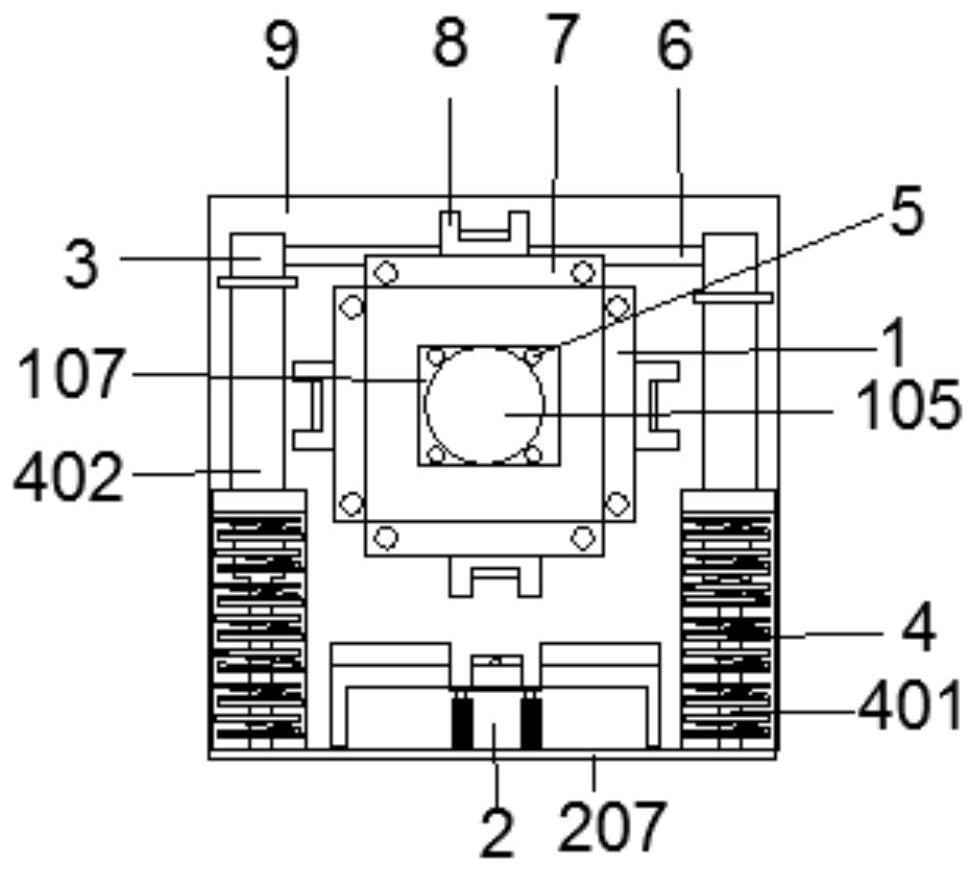

[0023] Example 1, such as Figure 1-3 As shown, a pressing device for assembly includes a body 9, a rotating mechanism 1, a shock absorbing mechanism 2 and a hydraulic mechanism 3;

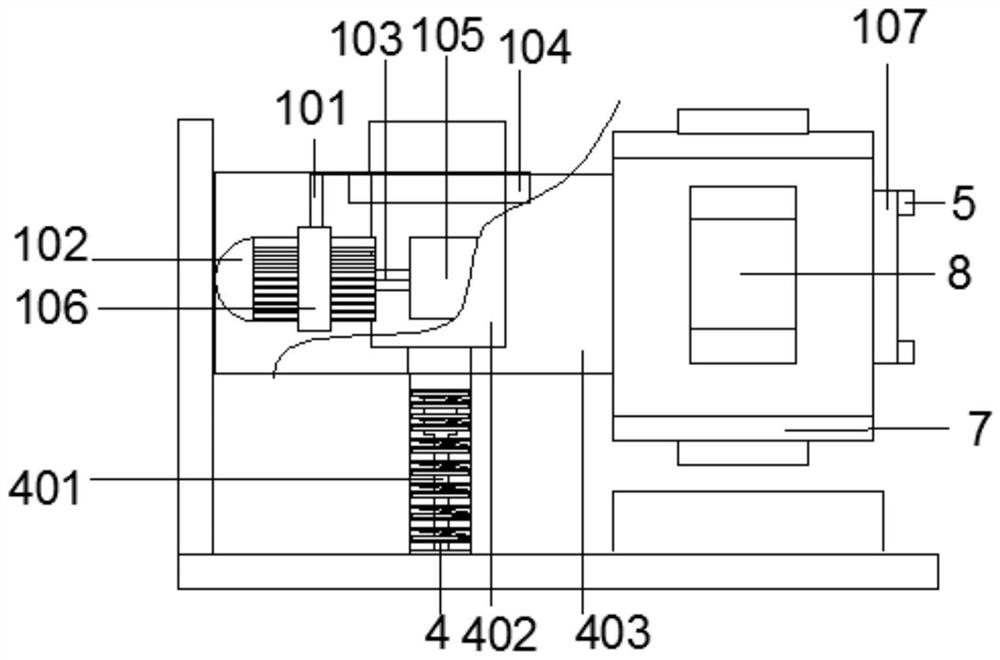

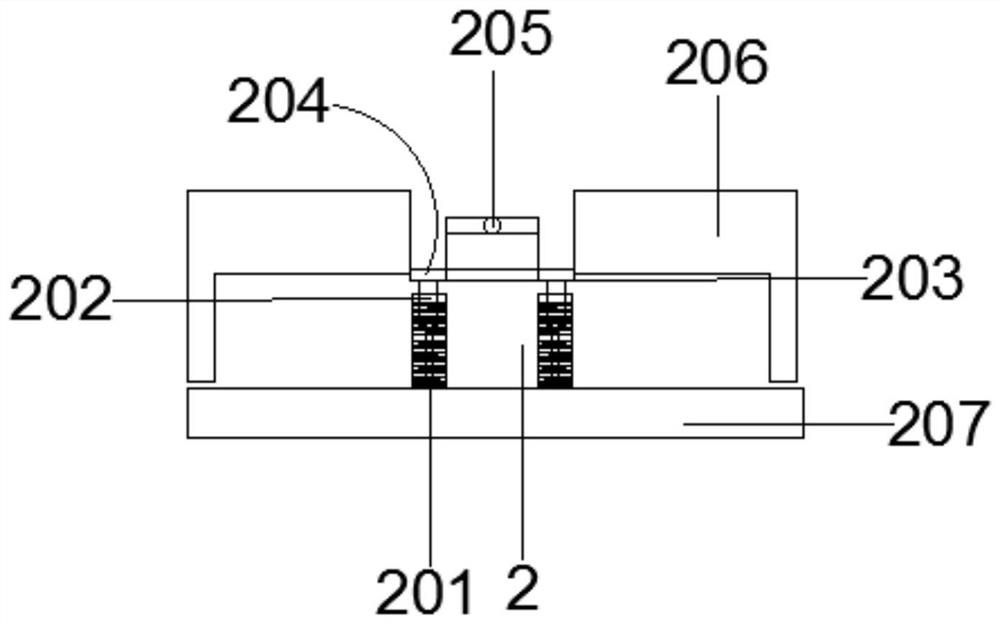

[0024] The rotating mechanism 1 comprises a DC motor 102 and a connection block 105, the right side of the DC motor 102 is rotatably connected with a rotating shaft 103, the right side of the connection block 105 is fixedly connected with a washer 107 by four screws 5, and the outer surface of the connection block 105 right side is surrounded by Both are fixedly connected with an iron plate 7, the outer surface of the iron plate 7 is fixedly connected with a template 8, the shock absorbing mechanism 2 includes a metal plate 207 and a metal block 206, and both sides of the top of the metal plate 207 are fixedly connected with shock absorbing springs 201, The top of the metal plate 207 is fixedly connected with a pillar 202 , the pillar 202 is embedded in the interior of the shock absorbing spring 2...

Embodiment 2

[0026] Embodiment 2, the tops of the two backing plates 204 are fixedly connected with screws 203, the two backing plates 204 are screwed with torsion nails 205, the metal block 206 is fixedly connected on the top of the metal plate 207, and the hydraulic mechanism 3 includes a column 401 and The cabinet body 403 is fixedly connected with a hydraulic cylinder 402 at the top of the two columns 401, the two columns 401 are embedded in the inside of the damping spring 4, the cabinet body 403 is fixedly connected at the top of the two columns 401, and the two hydraulic cylinders 402 The outer surface close to the top is fixedly connected with a piston rod 104, and the side opposite to the top of the hydraulic cylinder 402 is fixedly connected with a connecting rod 6, and the bottom at the center of the connecting rod 6 is fixedly connected with the top of the cabinet body 403, and the outer surface of the DC motor 102 A ferrule 106 is fixedly sleeved at the center of the surface, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com