Aluminum ingot production line

A production line and aluminum ingot technology, applied in ingot casting workshops, equipment for transporting casting molds, equipment for supplying molten metal, etc., can solve problems such as low intelligence, affecting production efficiency, and incomplete demoulding, and achieve improvement Production efficiency, efficiency improvement, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

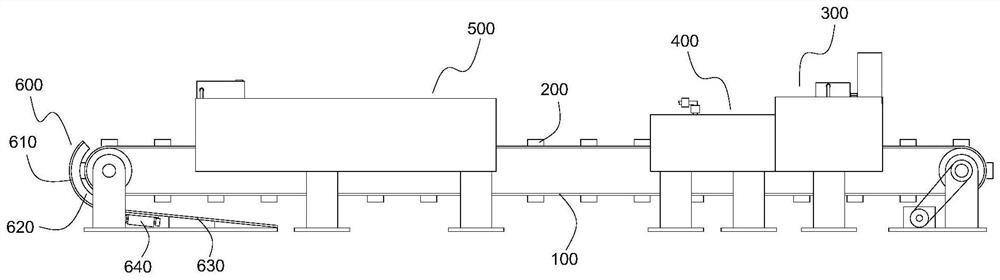

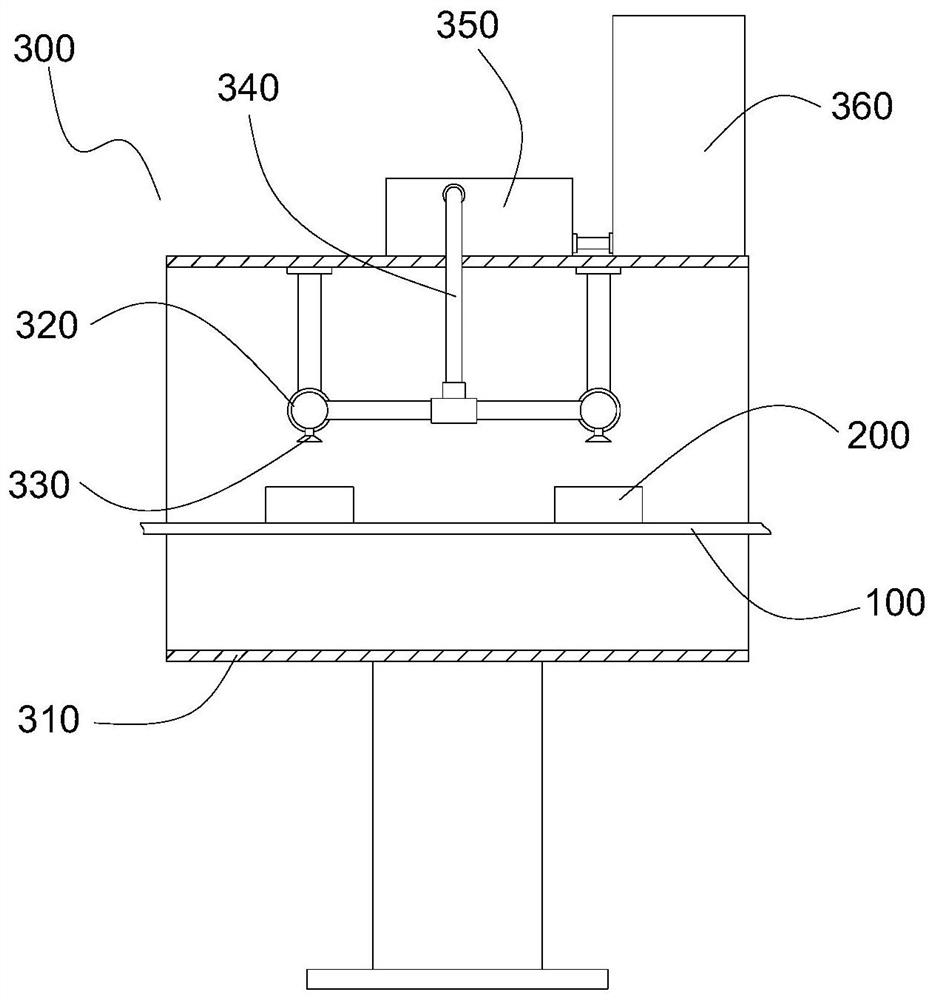

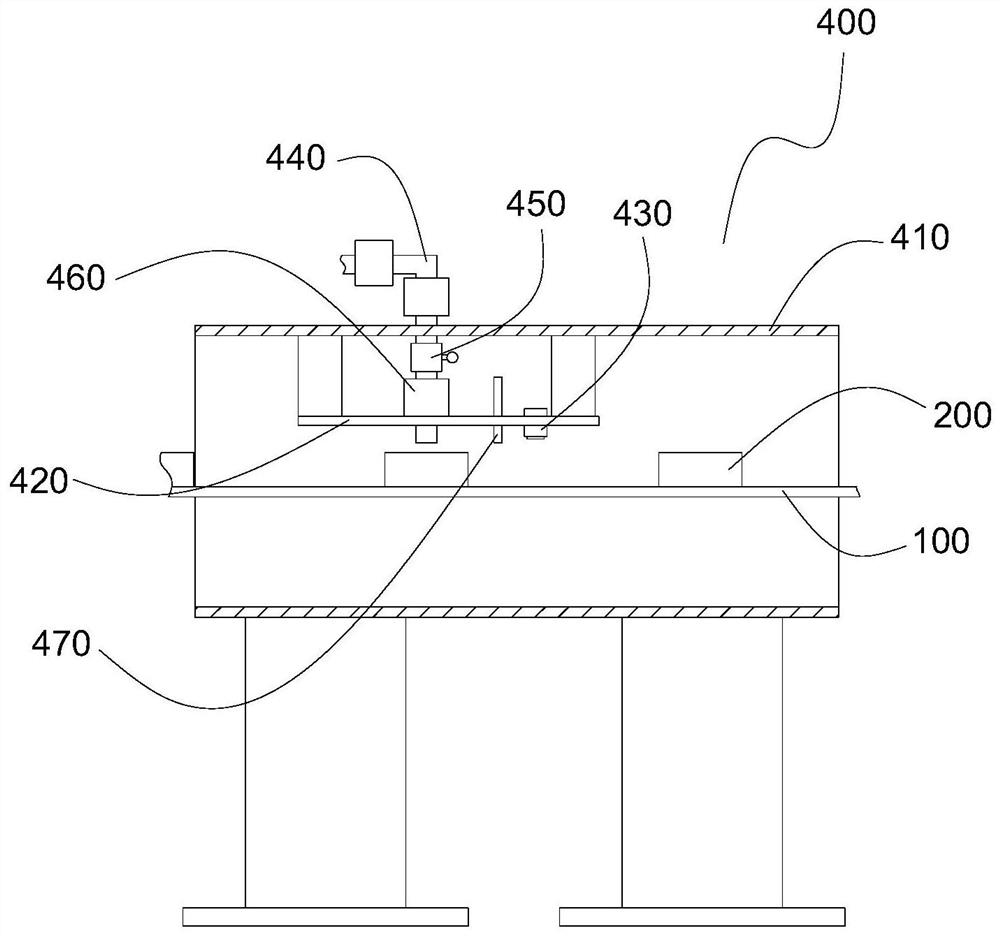

[0024] like Figure 1 to Figure 5 As shown, a specific embodiment of the present invention discloses an aluminum ingot production line, including a conveyor belt 100, forming molds 200 installed on the conveyor belt 100 in a linear array, and sequentially arranged along the conveying direction of the conveyor belt 100 The release agent spraying mechanism 300, the aluminum water pouring mechanism 400, the cooling mechanism 500, and the demoulding mechanism 600, the release agent spraying mechanism 300 is used to spray the mold release agent on the forming mold 200, and the aluminum water pouring mechanism 400 It is used to quantitatively inject aluminum water into the empty forming mold 200, and the cooling mechanism 500 is used to cool the forming mold 200 after injecting aluminum water, and remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com