A kind of numerical control cutter and its manufacturing method

A manufacturing method and cutting tool technology, which is applied in the direction of manufacturing tools, metal processing equipment, maintenance and safety accessories, etc., can solve the problems of decreased precision of workpieces, fast loss of tools, increased industrial costs, etc., to increase sealing performance and reduce broken knives Phenomenon, the effect of weakening mechanical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

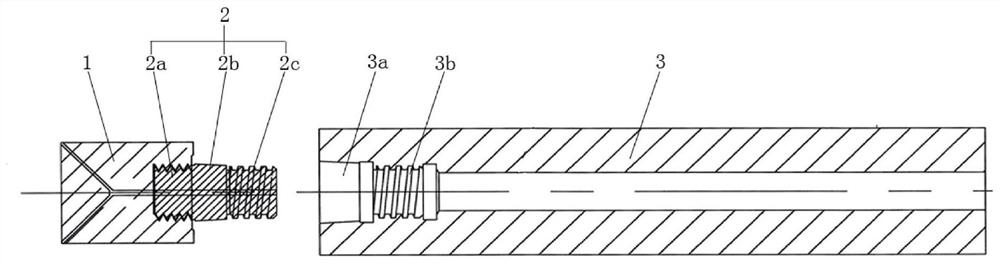

[0032] like figure 1 As shown, a numerical control tool includes a tool head 1, a tool shank 3 and a connecting piece 2 for connecting the tool head 1 and the tool shank 3, and the tool head 1, the tool shank 3 and the connecting piece 2 are arranged coaxially.

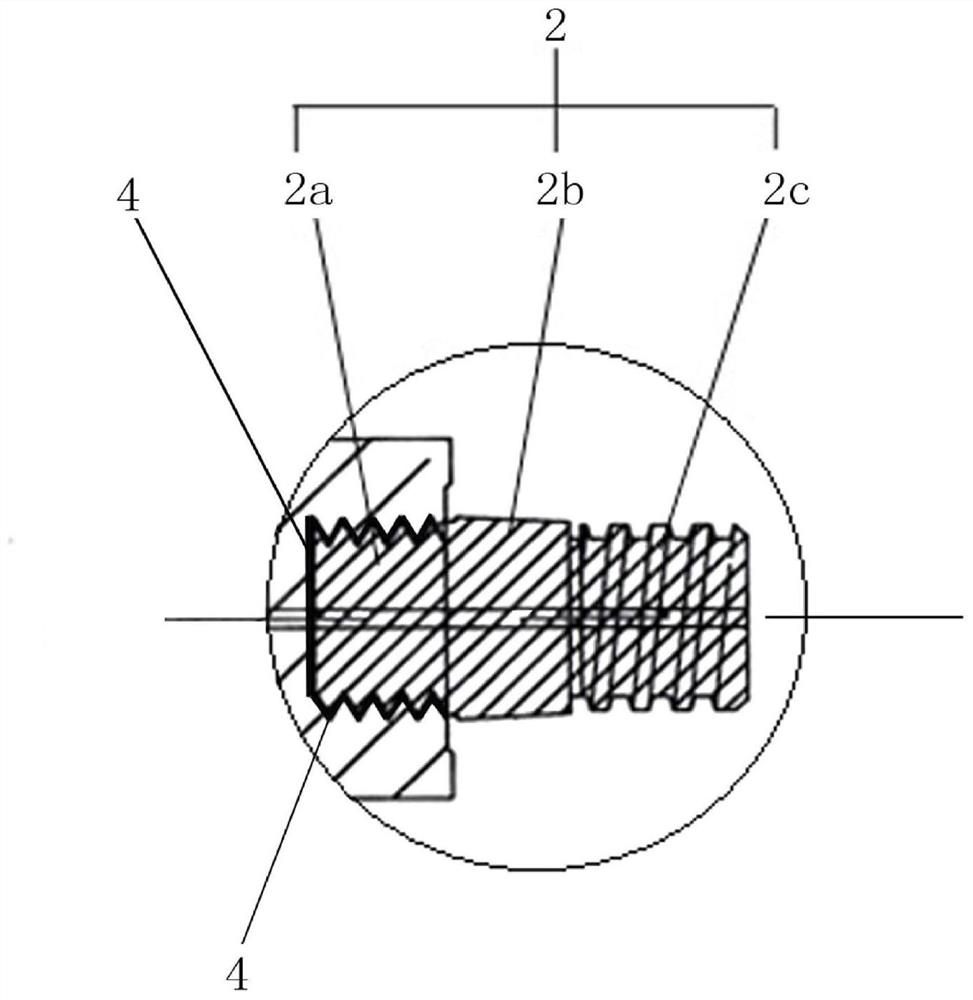

[0033] The connecting piece 2 includes a cutting head connecting section 2a and a cutting shank connecting section.

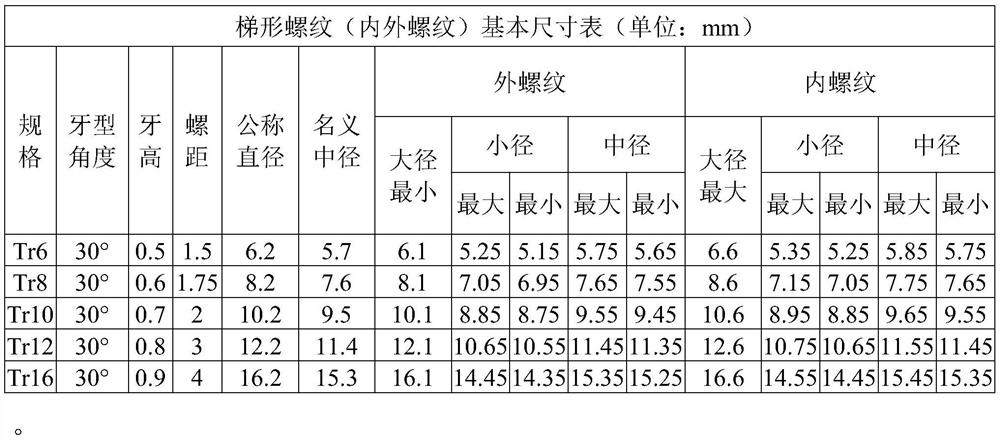

[0034] The cutter head connecting section 2a is provided with an external thread on the outer circumference, and the end of the cutter head 1 connected with the connecting piece 2 is provided with a cutter head connecting groove in the cutter head 1 along the axis of the cutter head 1, and the side wall of the cutter head connecting groove is provided with an inner thread , the inner thread is matched with the outer thread, and is used to connect the cutter head 1 to the connecting piece 2 . A shock-absorbing glue 4 is attached between the groove bottom and the side wall of the cutter head connecting ...

Embodiment 2

[0047] The embodiment of the present invention provides a method for manufacturing a numerically controlled tool, which can be used for processing and manufacturing the numerically controlled tool described in the first embodiment, which mainly includes the following steps:

[0048] Step 1: Select the cutter head 1 blank, and process the cutter head connecting groove along the axis direction of the cutter head 1 blank;

[0049] Step 2, machining an internal thread in the cutter head connecting groove, and the internal thread should be compatible with the external thread of the cutter head connecting section 2a;

[0050] Step 3: Pour the liquid shock-absorbing glue 4 into the connecting groove of the cutter head. Before the shock-absorbing glue 4 solidifies, install the connecting section 2a of the cutting head in the connecting groove of the cutting head. When installing, ensure that the cutting head 1 and the connecting piece are installed. 2, so that the shock-absorbing glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com