PCB drilling mechanism

A technology of PCB circuit board and drilling mechanism, which is applied in the direction of metal processing, etc., can solve the problems of large size, poor functionality, and inability to clean dust reasonably, and achieve the effects of improved functionality, easy welding, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

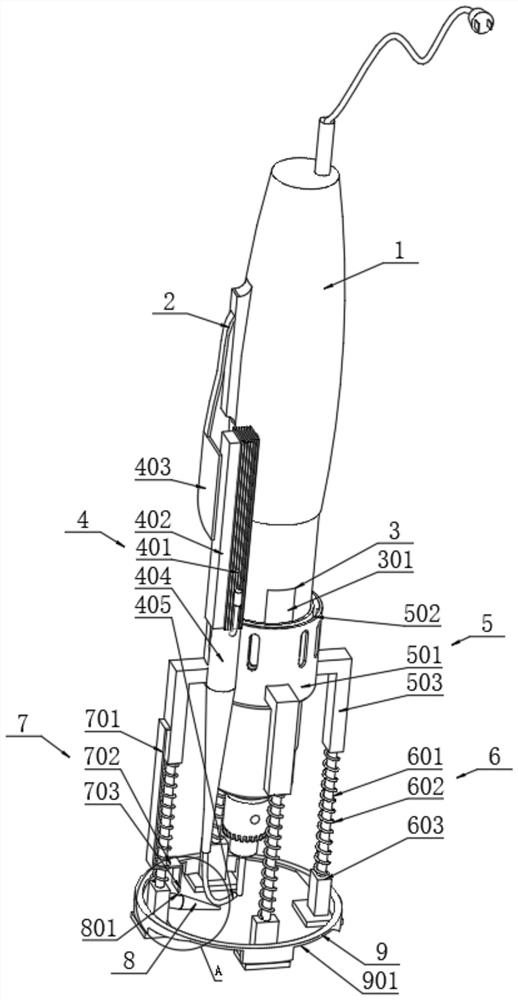

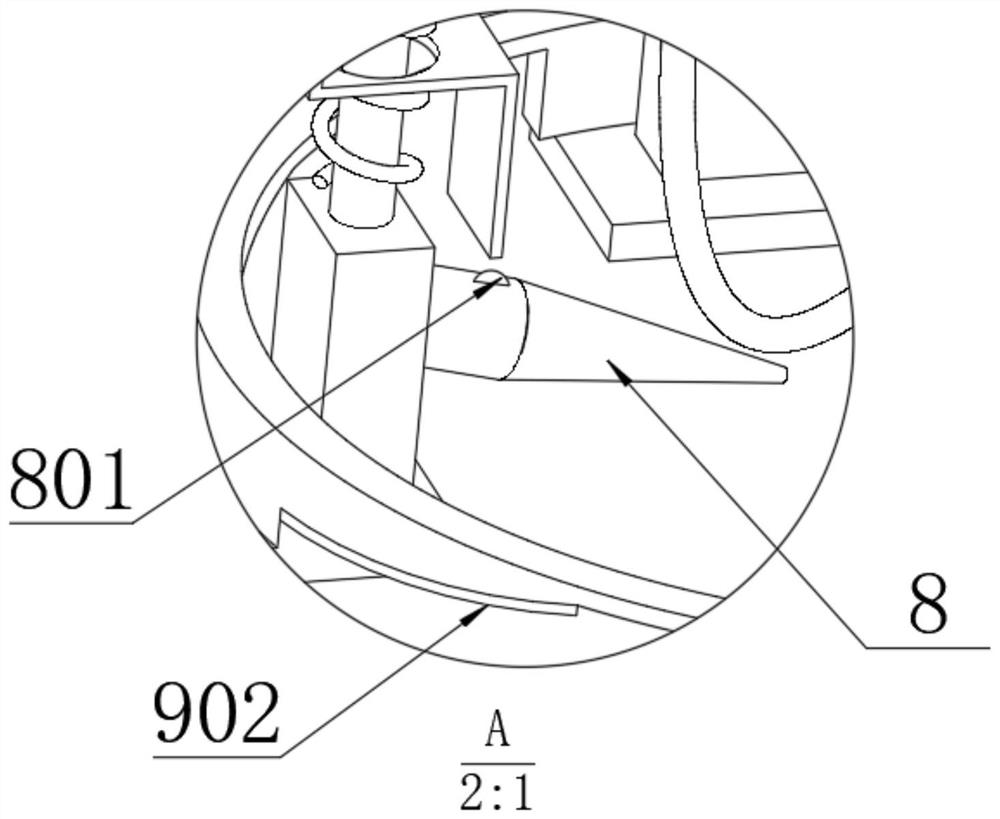

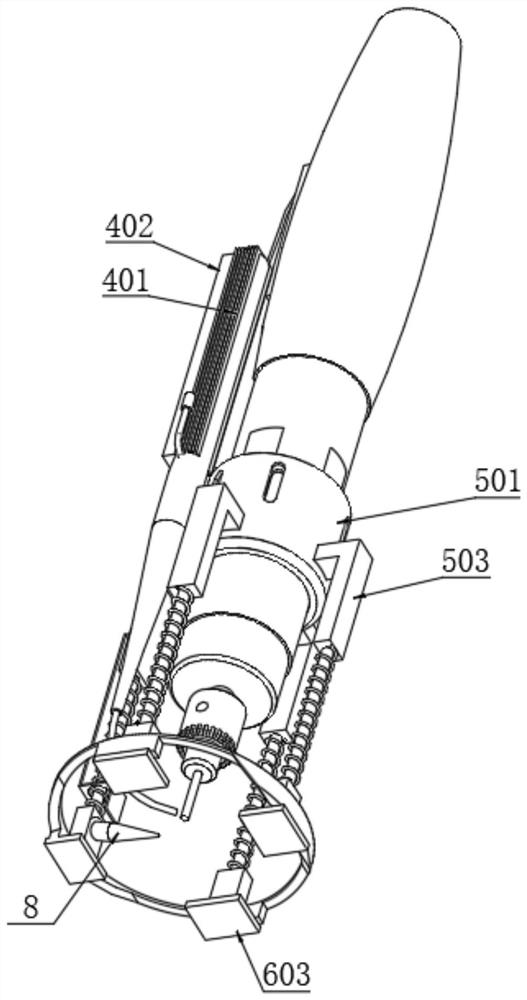

[0031] Refer to attached Figure 1-8 , a drilling mechanism for a PCB circuit board, comprising a drill pipe main shaft 1, a liquid cavity mechanism 4, a snap ring mechanism 5, a pressure rod mechanism 6, a starting mechanism 7, a fan cylinder 8 and a metal ring 9, the middle part of the drill pipe main shaft 1 There are four notches 3, and a limiting plate 301 is arranged in the notch 3, and a limiting ball 30101 is arranged on the outer wall of the limiting plate 301. ,Such as Figure 5 , Figure 8 As shown, the limiting plate 301 is installed in the notch 3 by means of a rotating shaft connection, and a spring plate 302 is connected between the bottom surface of the limiting plate 301 and the inner surface of the notch 3, and is fastened to the drill in a spring-pressed connection. The snap ring 501 on the rod main shaft 1 is limited and fixed. When removing the snap ring 501, you only need to press the limit plate 301 to remove the snap ring 501. It can be seen from this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com