Double-injection-port servo energy-saving injection mold opener

An energy-saving, double-injection technology, applied in the field of injection mold opening, can solve the problems of inconsistent color, difficult to clean, affecting strength, etc., to avoid secondary pollution, smooth the collection process, and avoid waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

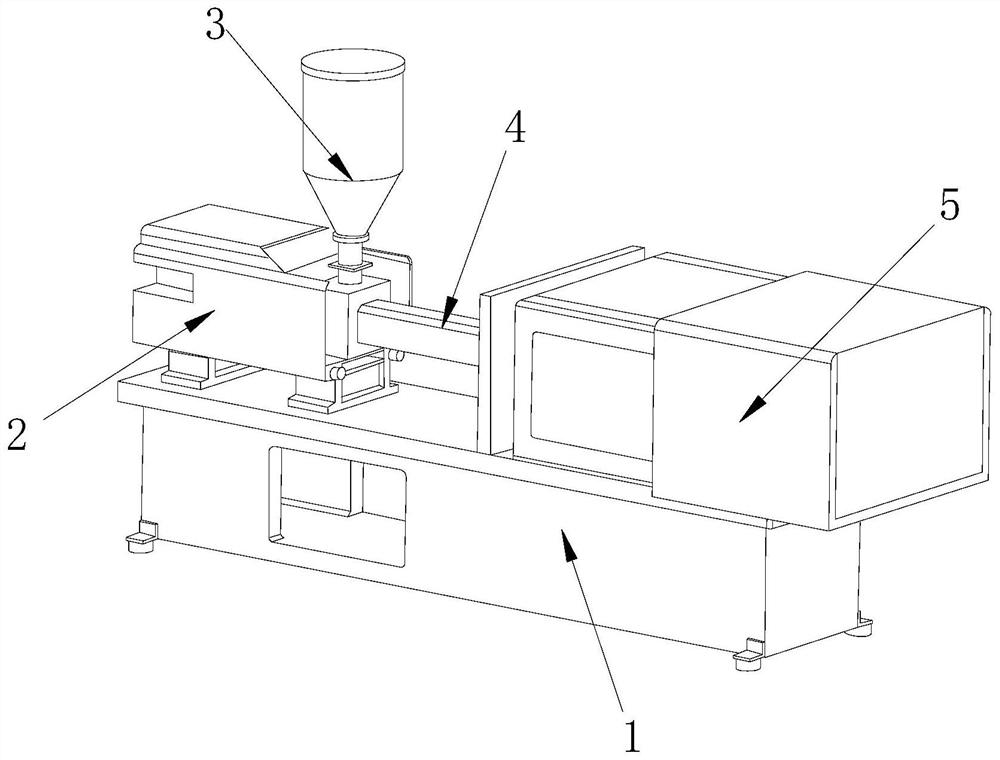

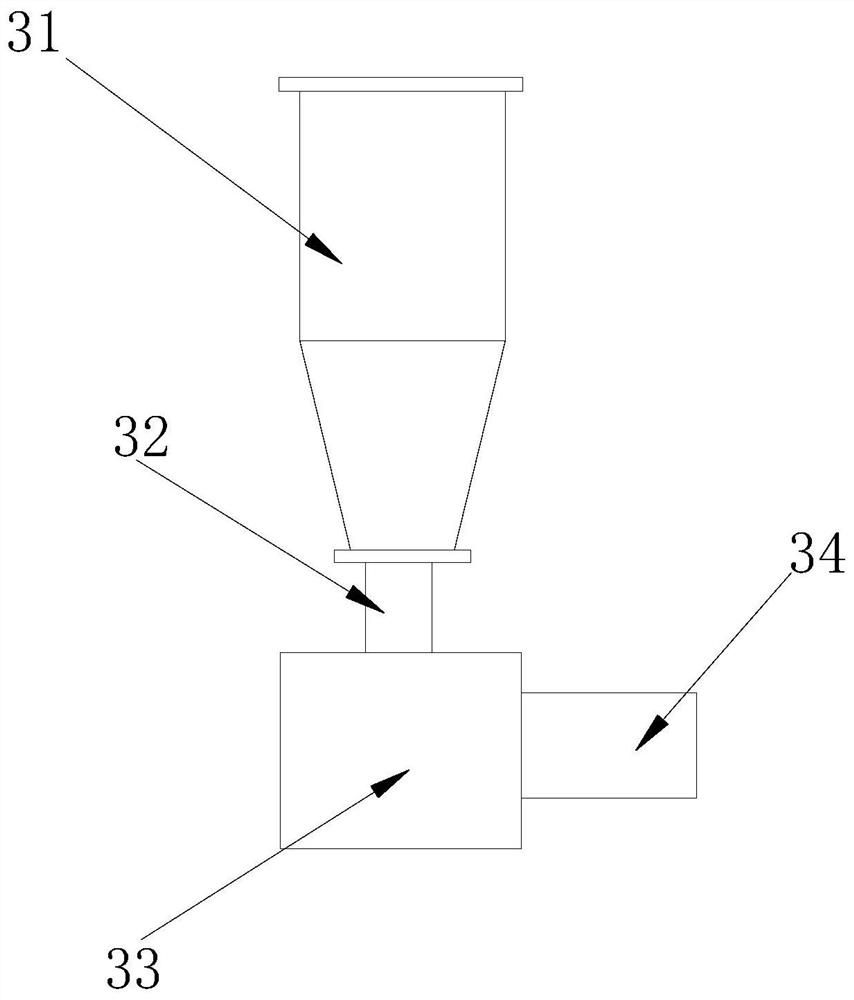

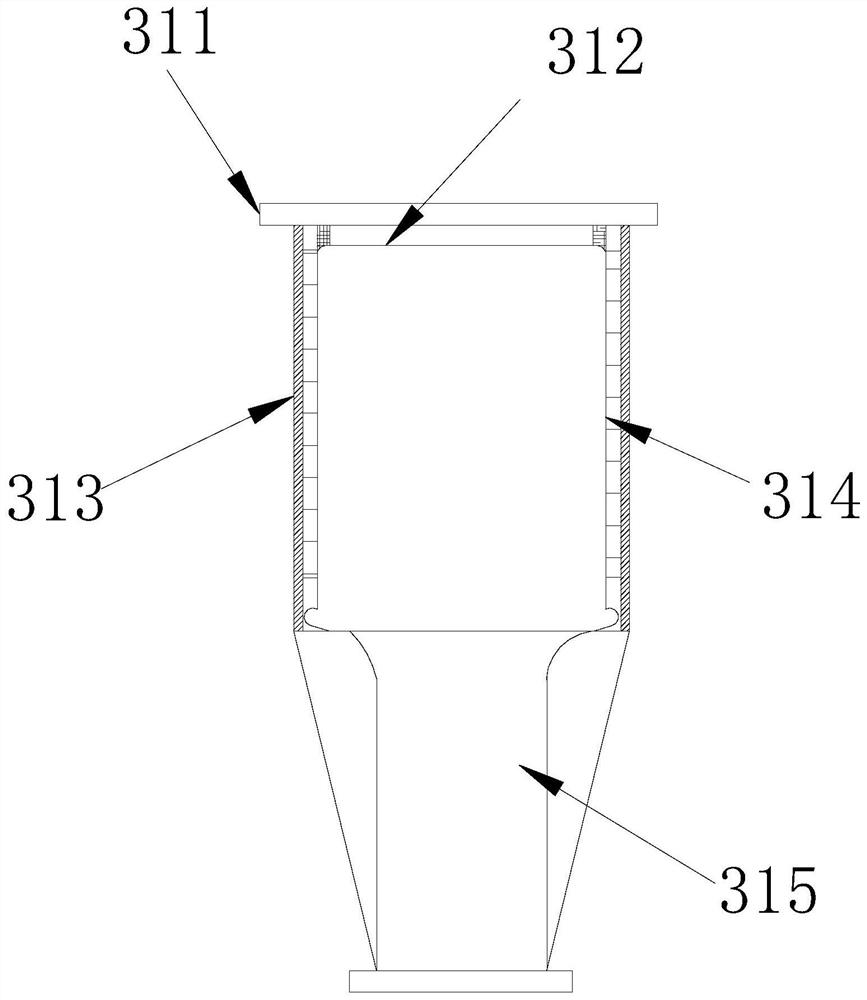

[0026] see Figure 1-Figure 5 , the specific embodiments of the present invention are as follows: a dual-injection port servo energy-saving injection mold opening machine, its structure includes a base box 1, a power box 2, an injection molder 3, a compression channel 4, and a mold opener 5. The base box 1 The top surface is welded to the bottom surface of the power box 2, the left side of the injection molding device 3 is mechanically connected to the right side of the power box 2, the right side of the injection molding device 3 is connected to the left side of the compression channel 4, and the right side of the compression channel 4 It is connected with the left side of the mold opener 5, and the bottom surface of the mold opener 5 is welded to the top surface of the base box 1; the injection molding device 3 includes a melting chamber 31, a transfer pipe 32, an extrusion seat 33, and a transfer pipe 34. The bottom surface of the melting chamber 31 is connected to the top ...

Embodiment 2

[0032] see Figure 1-2 , Figure 4 , Figure 6-Figure 8, the specific embodiments of the present invention are as follows: a dual-injection port servo energy-saving injection mold opening machine, its structure includes a base box 1, a power box 2, an injection molder 3, a compression channel 4, and a mold opener 5. The base box 1 The top surface is welded to the bottom surface of the power box 2, the left side of the injection molding device 3 is mechanically connected to the right side of the power box 2, the right side of the injection molding device 3 is connected to the left side of the compression channel 4, and the right side of the compression channel 4 It is connected with the left side of the mold opener 5, and the bottom surface of the mold opener 5 is welded to the top surface of the base box 1; the injection molding device 3 includes a melting chamber 31, a transfer pipe 32, an extrusion seat 33, and a transfer pipe 34. The bottom surface of the melting chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com