Passive side baffle of platform door

A platform door, passive technology, applied in the direction of stations, railway car body parts, roads, etc., can solve the problems of scratching trains, excessive gaps, installation errors, etc., to avoid electrical failures, reduce production costs and power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the embodiments shown in the accompanying drawings.

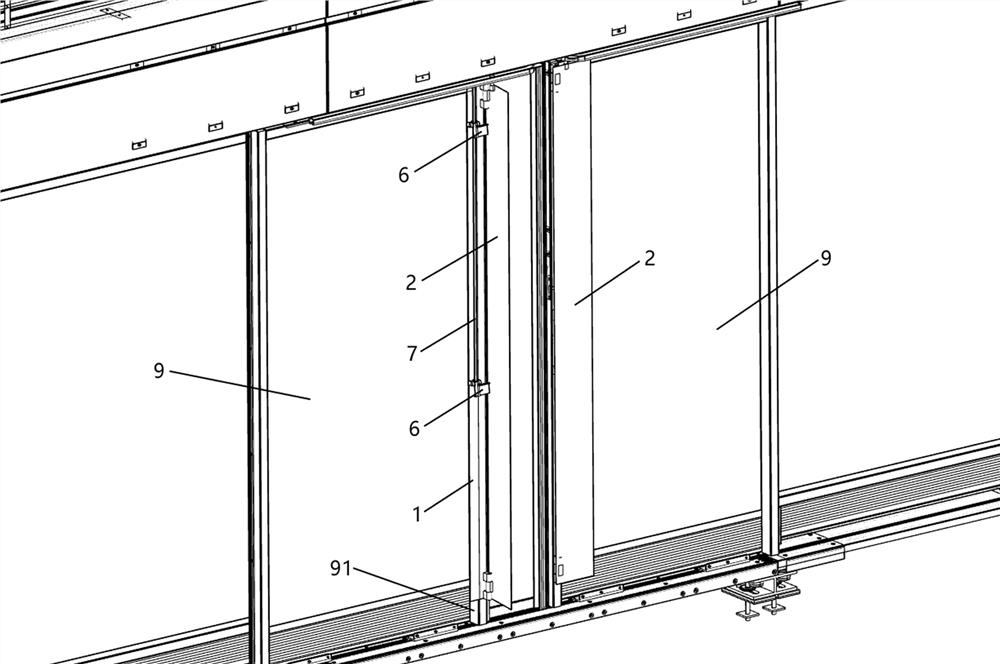

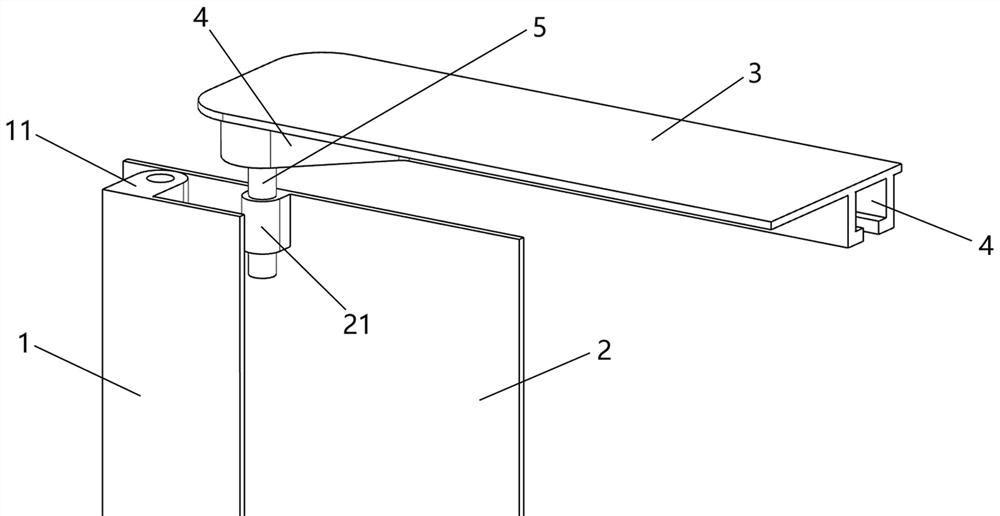

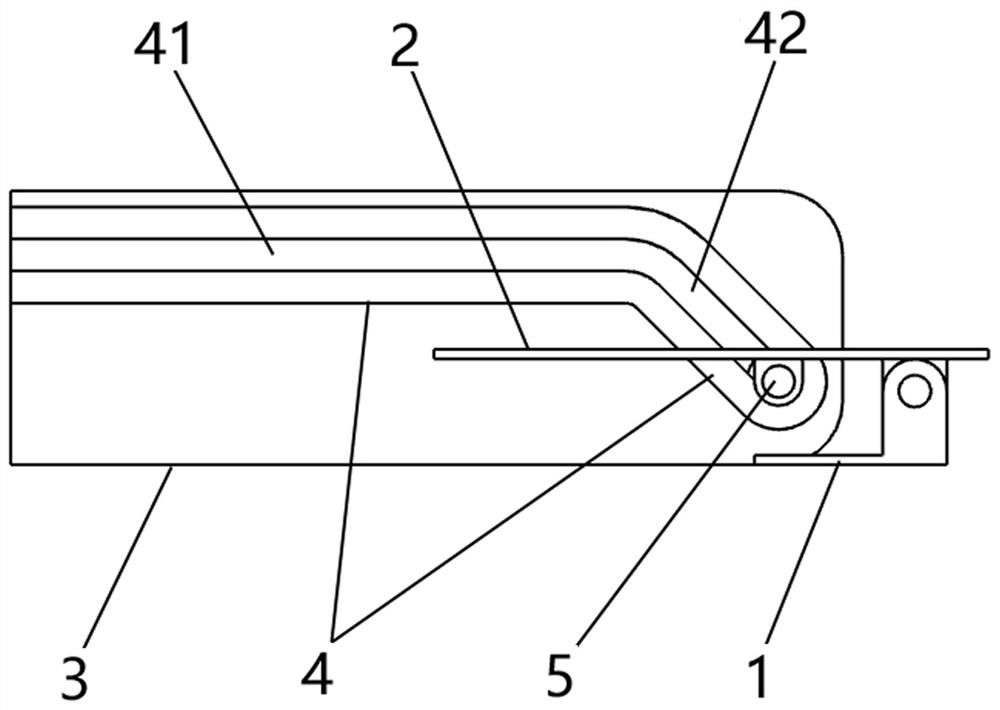

[0026] Such as figure 1 and Figure 6 As shown, the passive side baffle of the platform door of the present invention mainly includes: a sliding door fixing plate 1 , a baffle plate 2 , a door beam fixing plate 3 , a door beam guide rail 4 and a roller 5 .

[0027] Wherein, the sliding door fixing plate 1 is fixedly installed on the sliding door 9 of the platform door, preferably, the sliding door fixing plate 1 is installed on the vertical door frame 91 at one end of the closing direction of the sliding door 9 and close to the track side.

[0028] One side of the baffle plate 2 is hinged to the sliding door fixing plate 1 through a fixing plate hinge 11 so that it can be opened by turning outward or retracted by turning inward.

[0029] The door beam fixing plate 3 is fixedly installed on the sliding door 9 of the platform door bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com