Safety tongs linkage mechanism

A technology of linkage mechanism and safety gear, which is applied in the direction of elevators, transportation and packaging, etc., can solve the problems of low precision, relatively large impact of the lower brake parts, cumbersome operation, etc., and achieve the effect of increasing applicability and enhancing applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The present invention will be further described below in conjunction with the embodiments, but the present invention is not restricted in any way. Any changes or substitutions made based on the teachings of the present invention belong to the protection scope of the present invention.

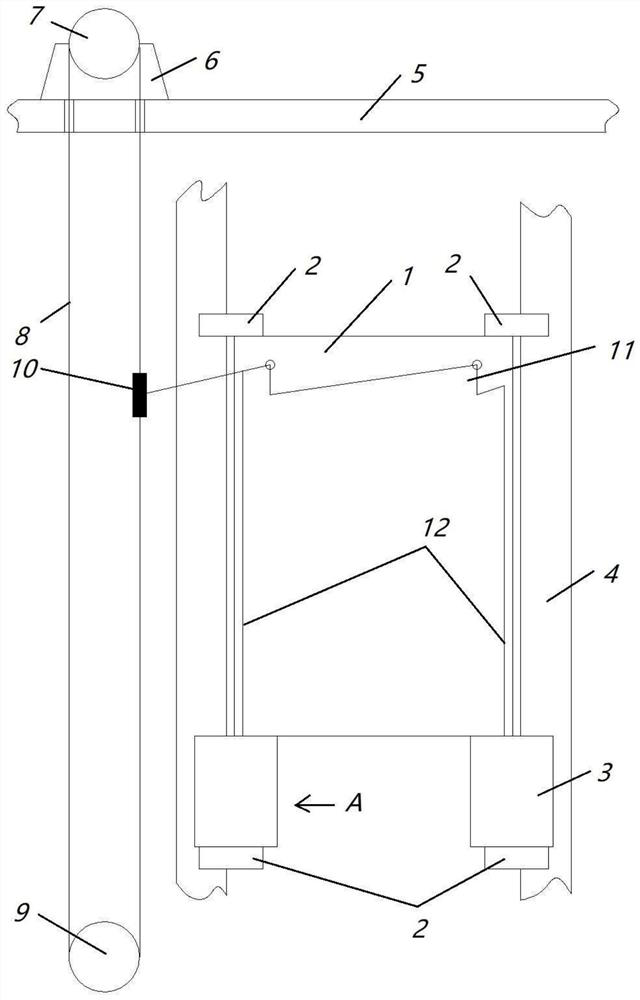

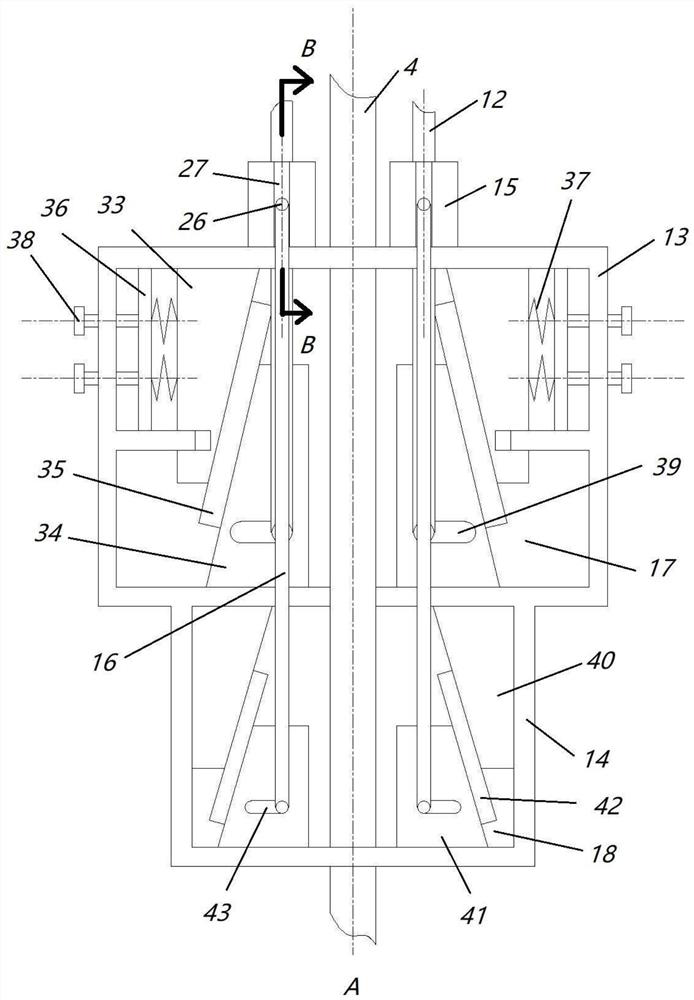

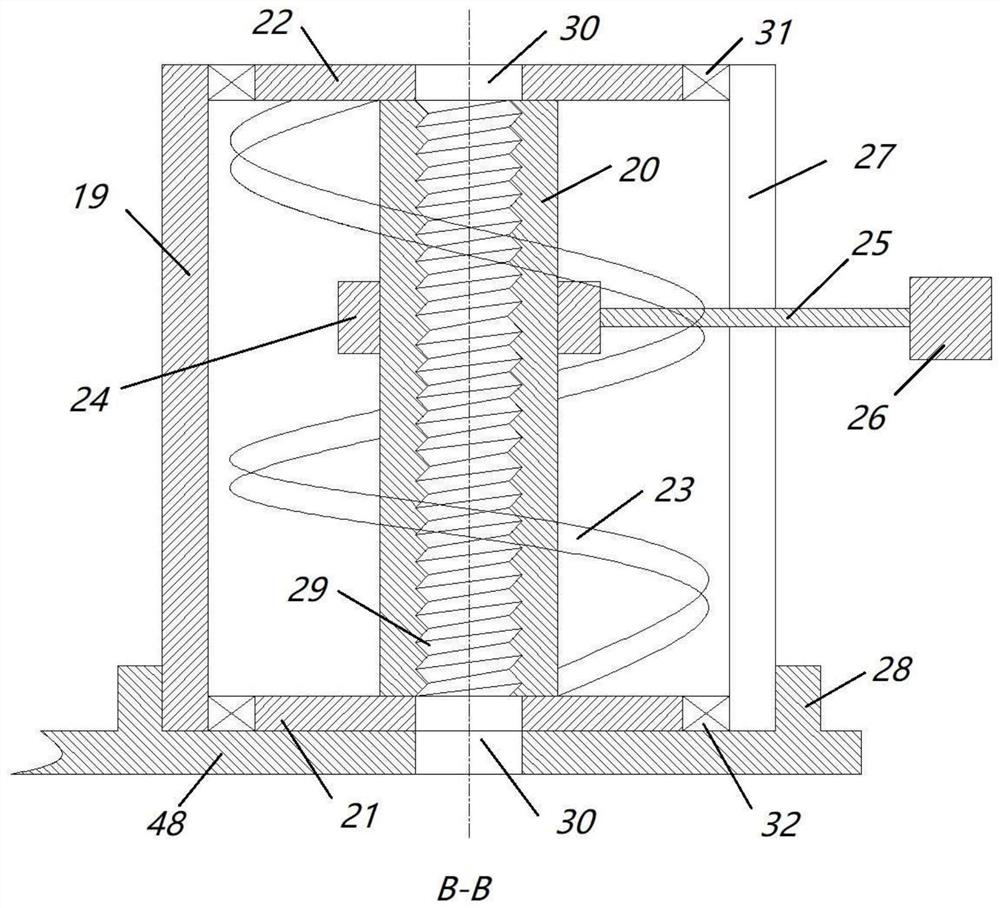

[0030]Such asFigure 1-3As shown, an elevator of the present invention includes a car 1, a guide shoe 2, a safety gear 3, a guide rail 4, a speed governor wheel 7, a speed governor wire rope 8, a speed governor tensioner 9, a linkage rod 11 and Lifting rod 12, the car 1 is lifted and lowered along the guide rail 4 under the guidance of the guide shoe 2, the safety gear 3 is installed at the bottom of the car 1, and the speed limiter is surrounded between the speed governor wheel 7 and the speed governor tensioner 9 Wire rope 8, one end of the linkage rod 11 is connected to the speed governor wire rope 8, and the other end is connected with a pull rod 12, and the lower end of the pull rod 12 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com