Multifunctional rod

A multifunctional and unified technology, applied in the field of multifunctional rods, can solve problems such as consumables, and achieve the effect of reducing the manufacturing process and increasing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

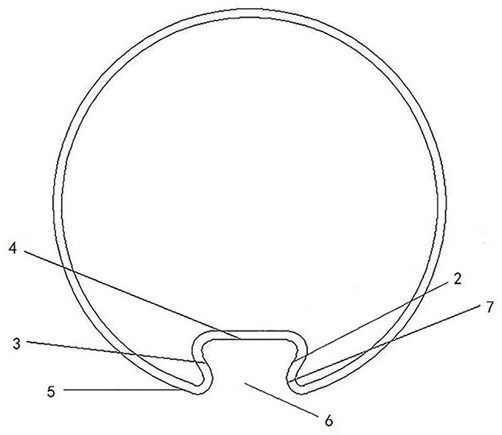

[0035]This embodiment provides a multifunctional pole 1, which is mainly used to improve the stability of the structure while saving materials. The multifunctional rod 1 includes: a first locking wall 2, a second locking wall 3, a connecting wall 4 and a supporting wall 5; the bottoms of the first locking wall 2 and the second locking wall 3 are connected by the connecting wall 4, In addition, the first locking wall 2 and the second locking wall 3 gradually approach outward from the connecting wall 4 to form a mounting opening 6 at their ends; the supporting walls 5 are arranged on both sides of the mounting opening 6 and corresponding to the mounting opening 6 The locking wall is connected to each other, and there is a buffer angle 7 between the supporting wall 5 and the correspondingly connected locking wall.

[0036]In this embodiment, such asfigure 2 , The first locking wall 2 and the second locking wall 3 are folded toward the inside of the multifunctional rod 1 along one end of t...

Embodiment 2

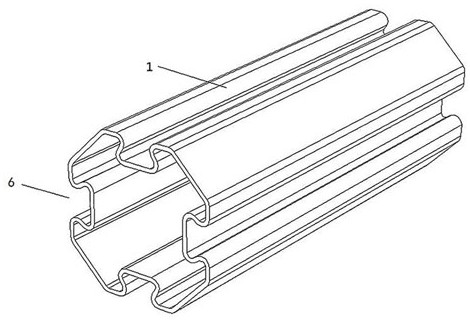

[0047]In this embodiment, unlike the single installation port 6 of the first embodiment, the multi-function pole 1 contains multiple installation ports. Due to the development of the 5G era, multiple devices need to be installed on the multi-function pole 1. For high-level installation of external equipment, the structure of the single installation port 6 is not enough to meet the demand. Therefore, the number of installation ports 6 can be determined according to different environments and the number of installation equipment and the direction of the installation equipment. Secondly, if multiple external devices need to be installed, the multi-function pole 1 of the single mounting port 6 can only be installed on the side of the multi-function pole 1 containing the mounting port 6, which is likely to be affected by the pulling force of the external device at the mounting port 6. Stability of multi-function lever 1. In order to ensure the stability of the multi-function pole 1 when ...

Embodiment 3

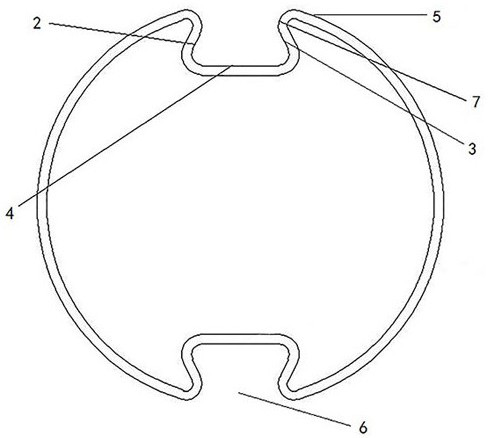

[0049]The difference between this embodiment and the above-mentioned first and second embodiments is as follows:Figure 6, The support wall 5 includes a flat support part 5-1, the flat support part 5-1 is arranged close to the installation opening 6 and connected with the locking wall on the corresponding side of the installation opening 6; the flat support of the support arms on both sides of the same installation opening 6 Section 5-1 is located in the same plane. On the one hand, one end of the flat support portions 5-1 on both sides of the installation opening 6 is connected to the corresponding locking wall to strengthen the locking wall, and the other end forms a certain angle with other parts of the support wall 5. The included angle is the same as the buffer angle in the first embodiment, which buffers the force received by the flat support portion 5-1. On the other hand, the flat support portions 5-1 on both sides of the installation port 6 are in the same plane. When the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com