Image detection and identification device and method for safety production line

An image detection and recognition device technology, applied in image communication, comprehensive factory control, television, etc., can solve the problems of difficulty in obtaining product images, low census rate, inaccurate image analysis, etc., to facilitate detection and analysis, and ensure production efficiency. , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

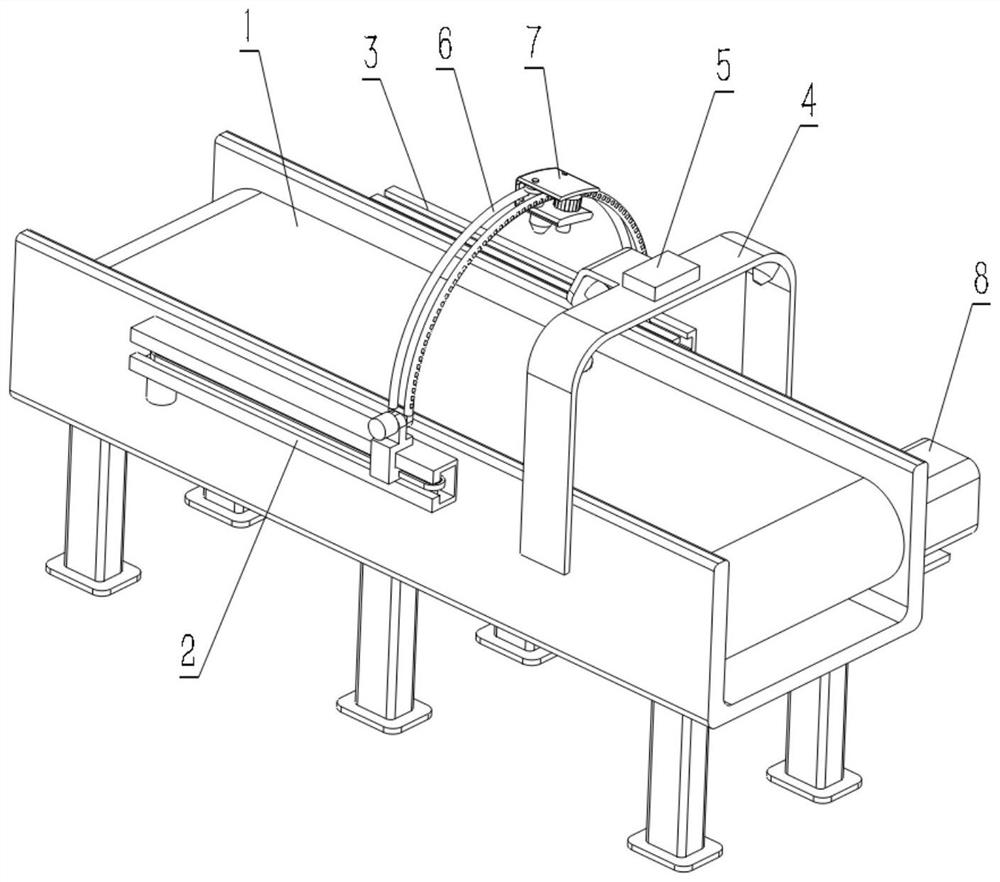

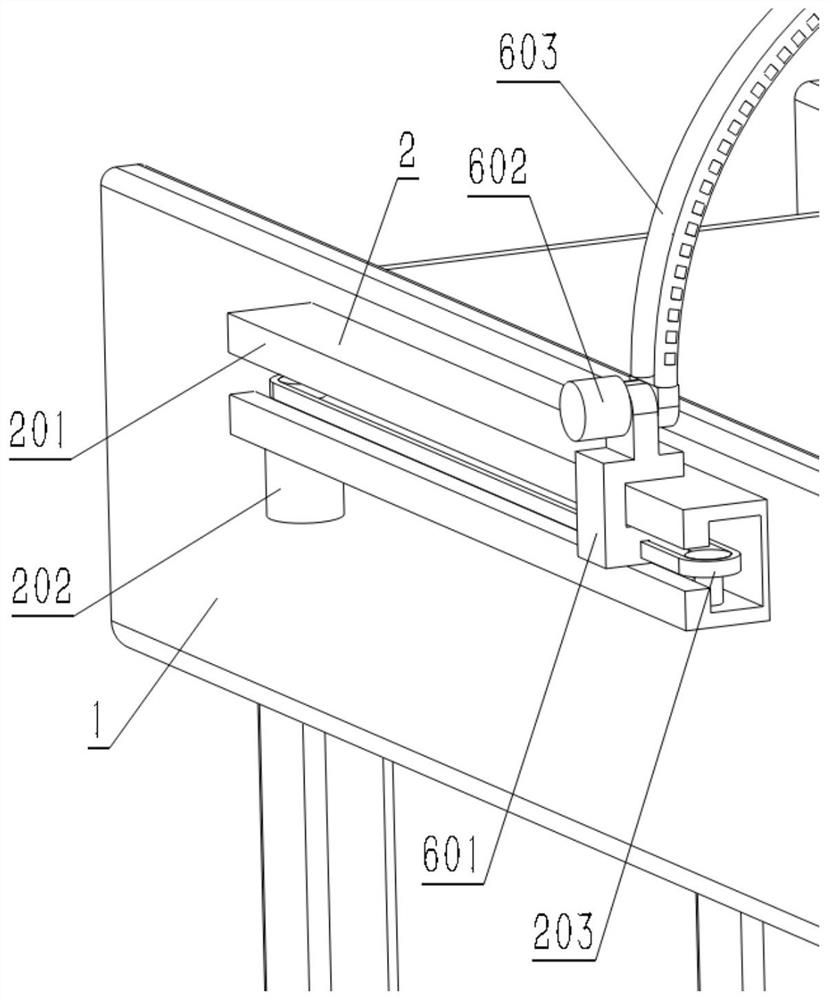

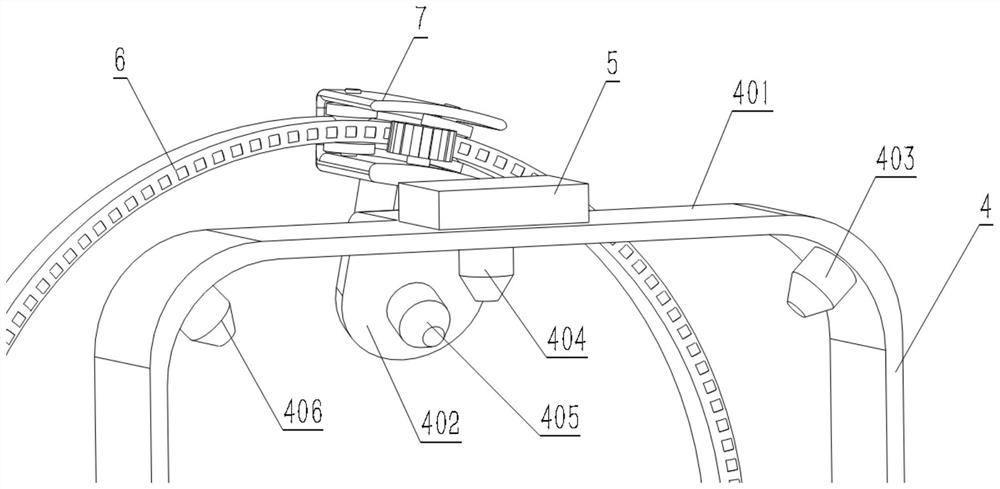

[0017] Such as Figure 1 to Figure 5 As shown, a safety production line image detection and recognition device according to the present invention adopts a technical solution that includes a transmission device 1, a transmission belt motor 8 is installed on one side of the transmission device 1, and the transmission device 1 is close to the transmission device 1. An image recognition frame 4 is fixedly installed at the initial end position of the direction, and the image recognition frame 4 includes a U-shaped camera mounting frame 401 spanning above the transmission device 1, and the middle part of the camera mounting frame 401 is fixedly connected with an oblique A panel 402, a first side camera 403 and a second side camera 406 are respectively installed on the left and right sides of the camera mounting frame 401, and the first side camera 403 and the second side camera 406 are all at a forty-eight angle to the vertical direction. Installed at an angle of five degrees and fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com