Graphite powder drying equipment

A technology of drying equipment and graphite powder, which is applied in drying, drying machines, lighting and heating equipment, etc., can solve the problems of poor drying effect of graphite powder, avoid pollution, prevent graphite powder agglomeration, and keep dry Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

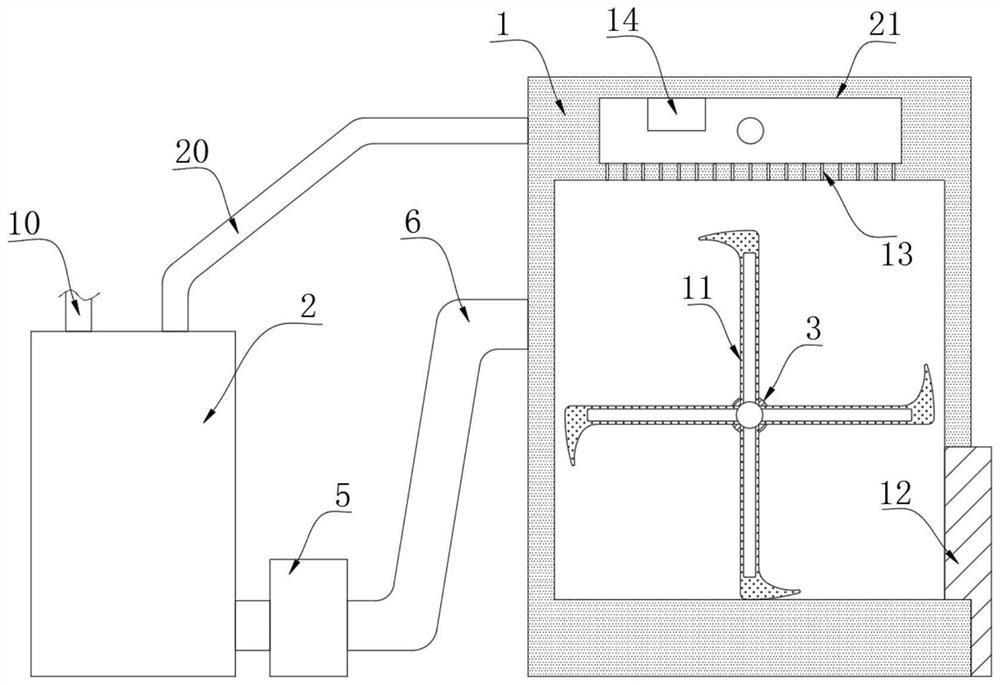

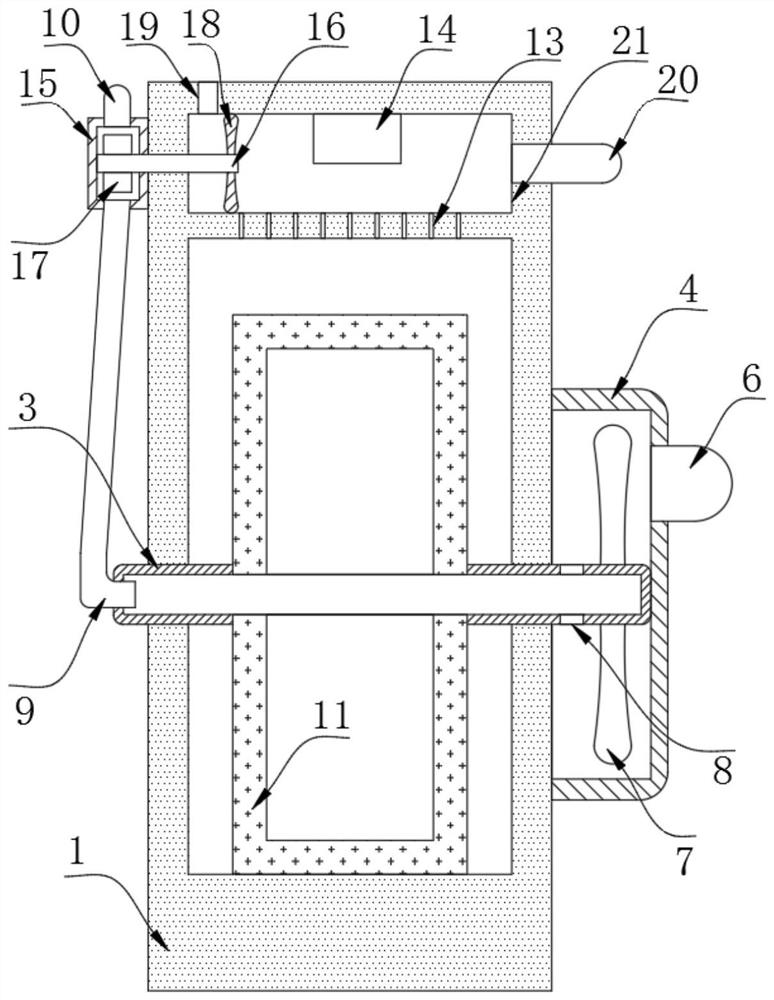

[0018] refer to Figure 1-2 , a graphite powder drying equipment, comprising a drying box 1 and a steam generator 2, the outer wall of the drying box 1 is fixed with a closed box 4, the exhaust pipe of the steam generator 2 is connected with a booster pump 5, the booster pump The exhaust port of 5 communicates with the inside of the closed box 4 through the inflatable tube 6. The side wall of the drying box 1 is connected with the rotating shaft 3 through the rotation. A plurality of air intake holes 8 are provided, a plurality of drying leaves 11 are inserted through the circumferential side wall of the rotating shaft 3 located in the inner part of the drying box 1, and a transition pipe 9 is inserted through the end of the rotating shaft 3 away from the closed box 4, The transition pipe 9 is connected with a return pipe 10 through a transition mechanism, and the return pipe 10 communicates with the steam generator 2 to return the unused steam and cooling water to the water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com