A high voltage transmission line deicer

A high-voltage transmission line and deicer technology, applied in the mechanical field, can solve problems such as easy card grouping and large resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

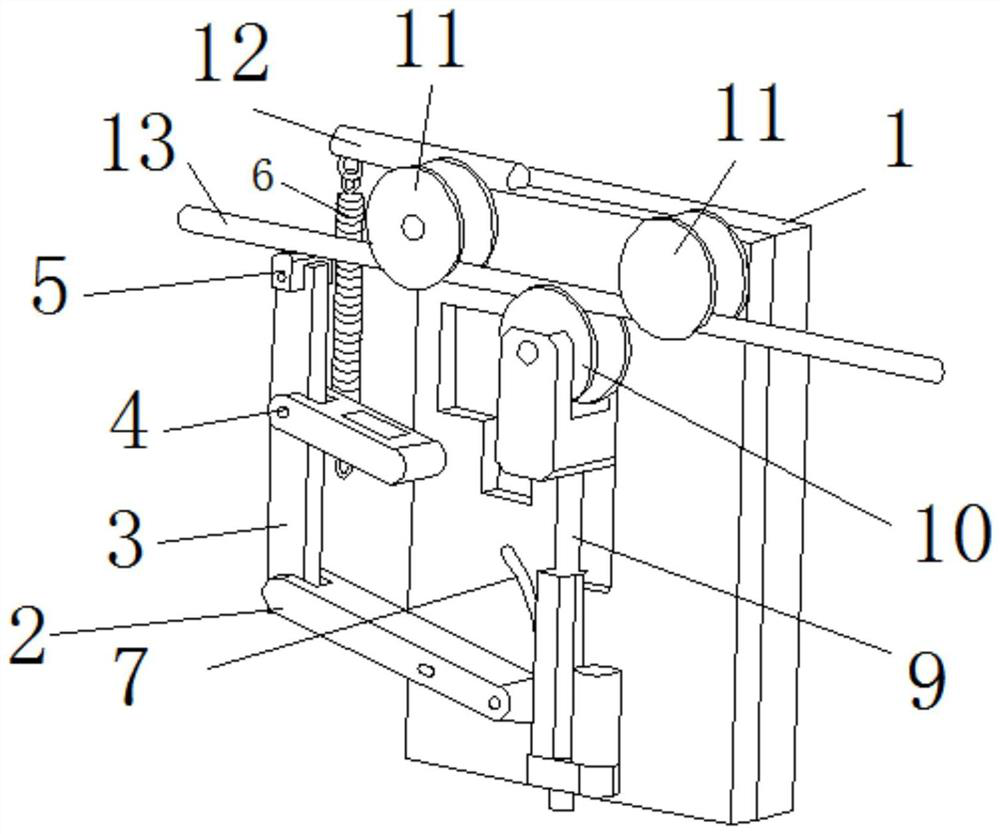

[0023] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

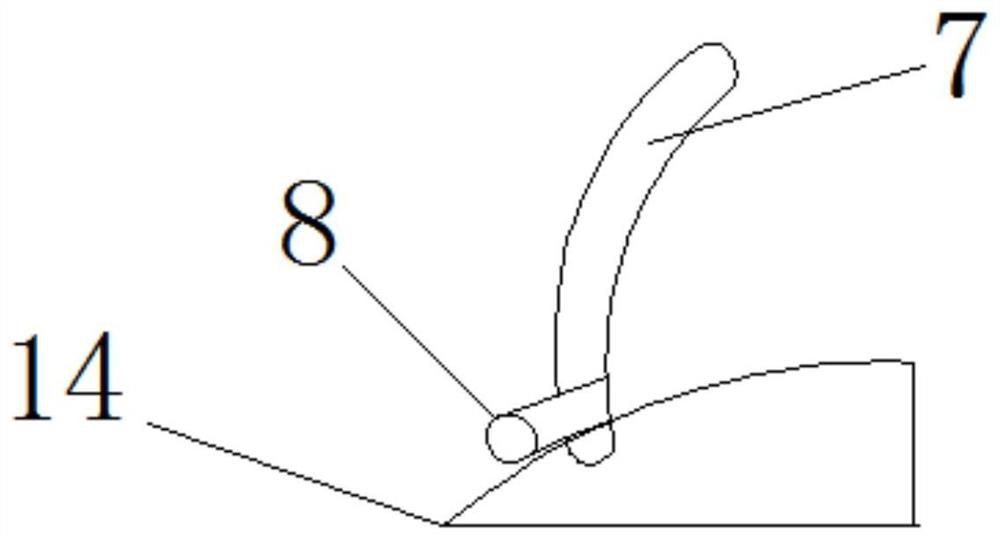

[0024] This embodiment proposes a high-voltage transmission line deicer, such as figure 1 and 2 As shown, it includes a back plate 1, a first connecting rod 2, a second connecting rod 3, a third connecting rod 4, a hammer body 5, a first elastic element 6, an arc-shaped slot 7, a pin 8, a lifting motor 9, a first Two rollers 10, first roller 11, fixed shaft 12, linear motor 14, cam 15, rotating motor 16, second elastic element 17, second contact sensor 18, first contact sensor 19, shifting block 20.

[0025] Wherein the first roller 11 and the second roller 10 are arranged up and down, and both are arranged on the front of the backboard 1 , the number of the first ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com