Mixing and preparing device for concrete materials

A technology for configuring equipment and concrete, which is applied in the direction of clay preparation equipment, cement mixing equipment, chemical instruments and methods, etc. It can solve the problems of uneven mixing, time-consuming and laborious, etc., and achieve the effect of convenient access and prevention of splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

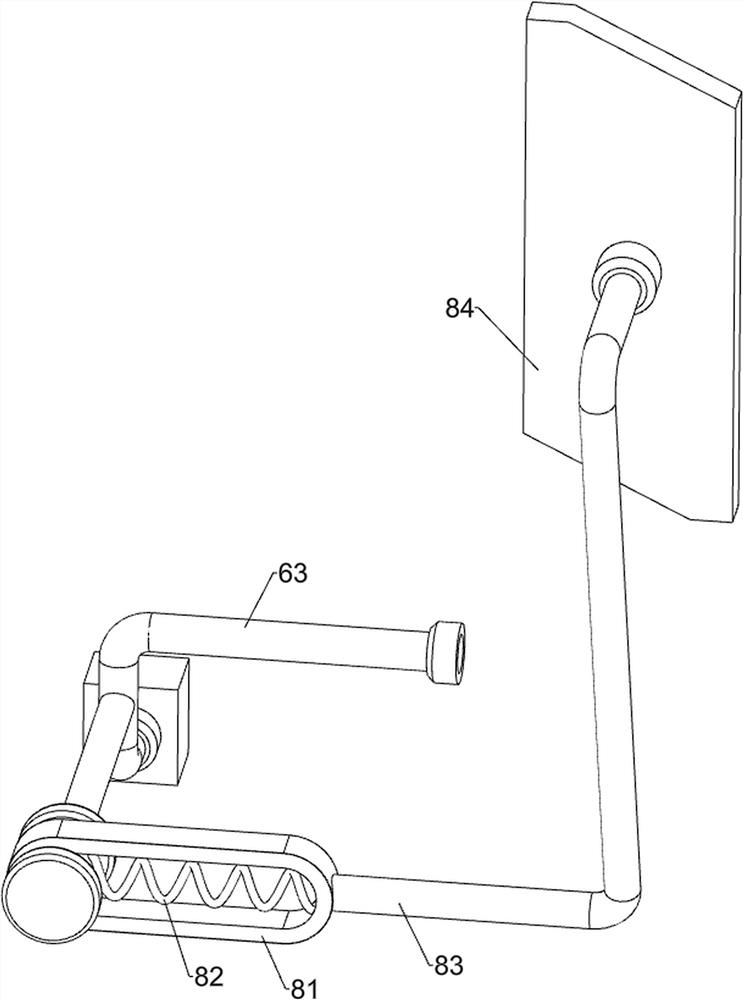

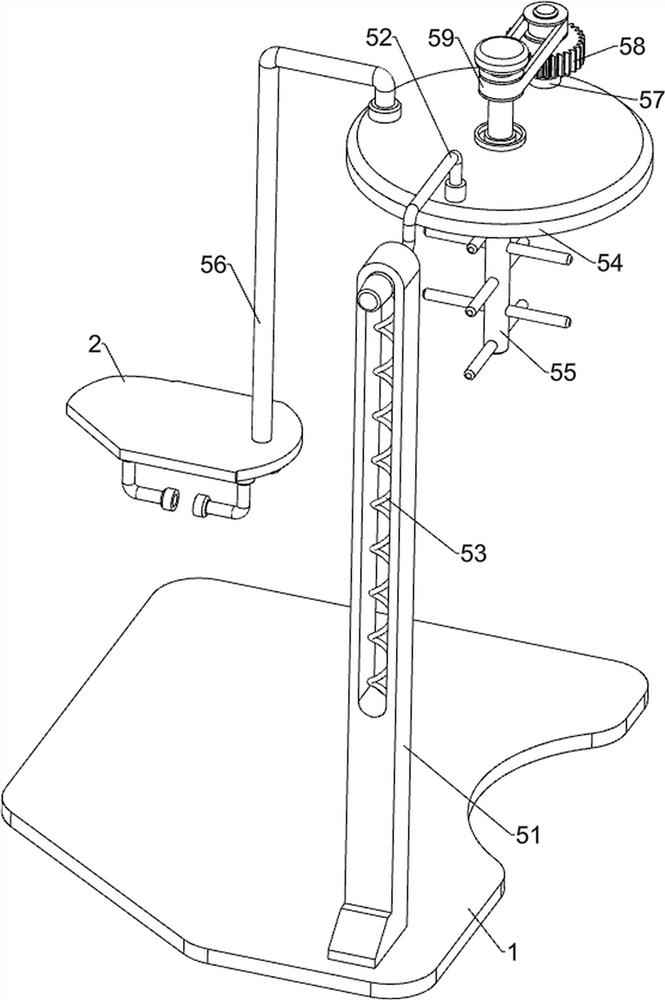

[0024] A mixing arrangement for concrete materials such as Figure 1-4 As shown, it includes a base 1, a frame 2, a mixing bucket 3, a driving assembly 4, a mixing configuration assembly 5, and a tilting assembly 6. The upper side of the base 1 is equipped with a frame 2, and the mixing bucket is installed on the frame 2 in a rotating manner. 3. The driving assembly 4 is installed on the upper side of the frame 2, the mixing configuration assembly 5 is installed between the base 1 and the frame 2, and the tilting assembly 6 is installed between the frame 2 and the mixing barrel 3.

[0025] Put the concrete material into the mixing bucket 3, start the driving assembly 4, control the mixing configuration assembly 5 to move downward, and then make some parts in the mixing configuration assembly 5 cooperate with some parts of the driving assembly 4, so that the mixing configuration assembly 5 is The concrete material in the mixing bucket 3 is mixed, then the drive assembly 4 is tu...

Embodiment 2

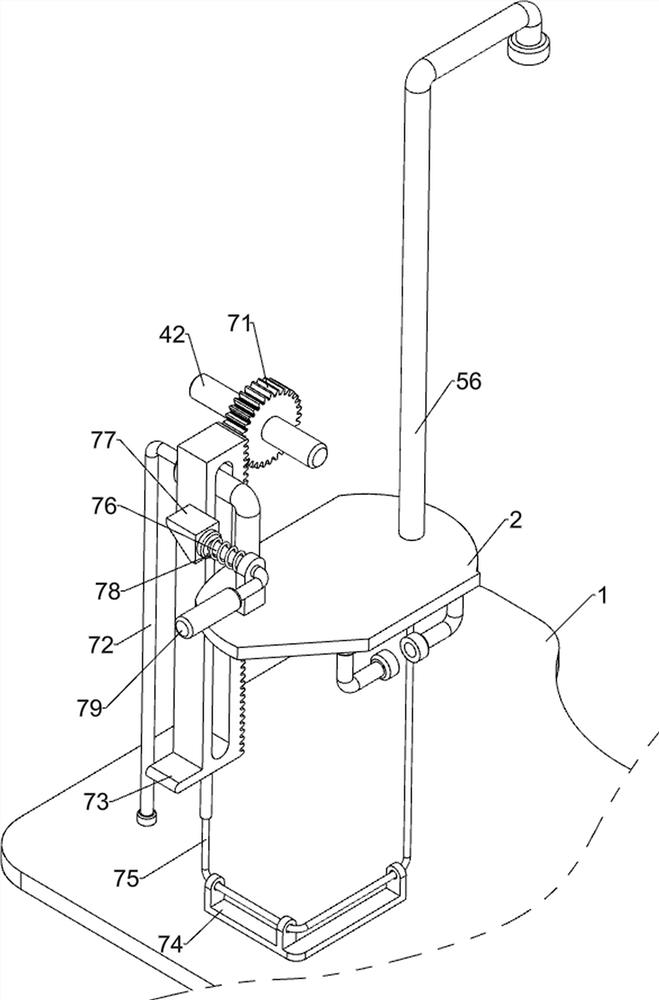

[0033] On the basis of Example 1, such as Figure 5 and Figure 6 As shown, it also includes a pull clamp assembly 7, and the pull clamp assembly 7 includes a fourth gear 71, a guide rod 72, a large rack 73, a guide frame 74, a pull wire 75, a right-angle rod 76, a wedge block 77, a third Spring 78 and handle 79, the middle part of the first rotating shaft 42 is connected with the 4th gear 71, is connected with guide rod 72 on the frame 2, is provided with large rack 73 slidingly on the guide rod 72, large rack 73 and the fourth The gears 71 are meshed with each other, and a guide frame 74 is installed on the upper left side of the base 1, and a backguy 75 is connected through the guide frame 74 between the underside of the large tooth bar 73 and the underside of the guide rod 56, and the left part of the frame 2 The upper side sliding type is equipped with a right-angle bar 76, and the rear side of the right-angle bar 76 is connected with a wedge block 77, and the wedge bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com