Device for treating coal dust during coal transportation for coal-fired power plant

A technology for coal-fired power plants and treatment devices, applied in separation methods, filtration separation, and dispersed particle separation, etc., can solve problems such as frequent failures, large water consumption, and increased operating resistance, and achieve maintenance-free emissions, reliable operation, and maintenance simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit this invention.

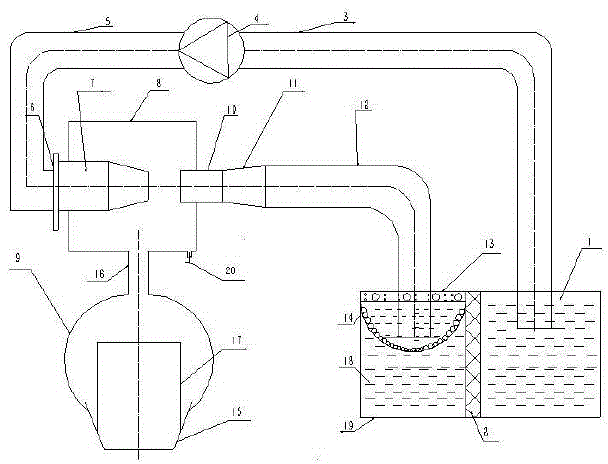

[0014] please see figure 1 , a kind of coal dust treatment device for coal transportation in a coal-fired power plant provided by the present invention, comprising a water supply chamber 1, a pump inlet pipe 3, a low-pressure water supply pump 4, a pump outlet pipe 5, a multiphase fluid vacuum dust removal chamber, and a dust collection hood 9. Diffusion pipe 11, coal dust slurry outlet pipe 12, coal dust filtration and precipitation chamber; multiphase fluid vacuum dust removal chamber includes water inlet nozzle 7, coal dust inlet 16, multiphase fluid vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com