Low-temperature carbonization apparatus and method for oil sand, oil sludge, oil shale and biomass

An oil shale and biomass technology, applied in the field of energy development, can solve the problems of low raw material utilization rate, low equipment operation rate, low tar yield, etc., and achieve the goal of solving difficult processing problems, high degree of automation, and high heat utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

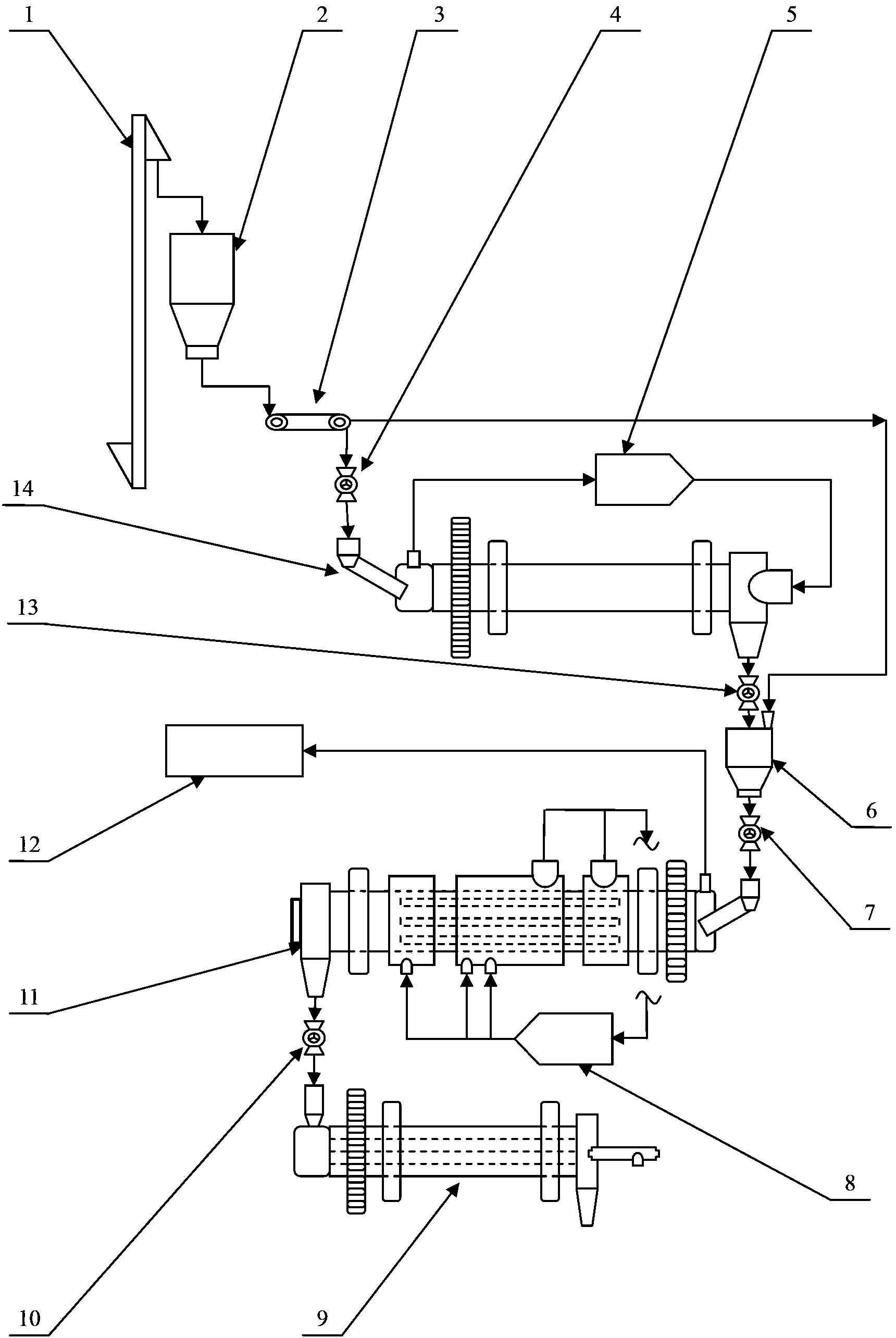

[0055] The method for the low-temperature dry distillation of oil sands, oil sludge, oil shale and biomass will be described below to illustrate the embodiment of the present invention, comprising the following steps:

[0056] 1) Solid materials such as raw material oil shale, oil sand, oil sludge (ground oil sludge, tank bottom oil sludge, oil refinery sludge), biomass (wood, straw, solid waste, etc.) are crushed and screened to the required particle size After that, it is sent to the raw material bin 2 through the conveying equipment 1. According to the moisture content of the raw material and the process requirements, for the material that needs to be dried and preheated, it is measured by the metering device 3 and sent to the drying furnace 14 through the 1# feed air lock device 4;

[0057] 2) After drying, dehydration, and preheating, it is sent to the buffer bin 6 through the 1# discharge air lock device 13, and the buffer bin 6 enters the rotary retort furnace 11 through...

Embodiment 1

[0076] 1) Crushing and screening the raw oil sand to ≤6mm, the bulk density of the raw oil sand used is 1200kg / m 3 , the oil sands industry analysis results are as follows:

[0077] serial number

Test items

Test results

1

Moisture Mad

0.74%

2

Ash Aad

78.07%

3

Volatile matter Vad

16.33%

4

Fixed Carbon FCad

5.60%

[0078]2) The raw material oil sand is sent to the raw material storage bin by the belt, and after being measured by the belt scale, it is sent to the rotary retort furnace through the buffer bin at a speed of 1.2t / h through the star feeder;

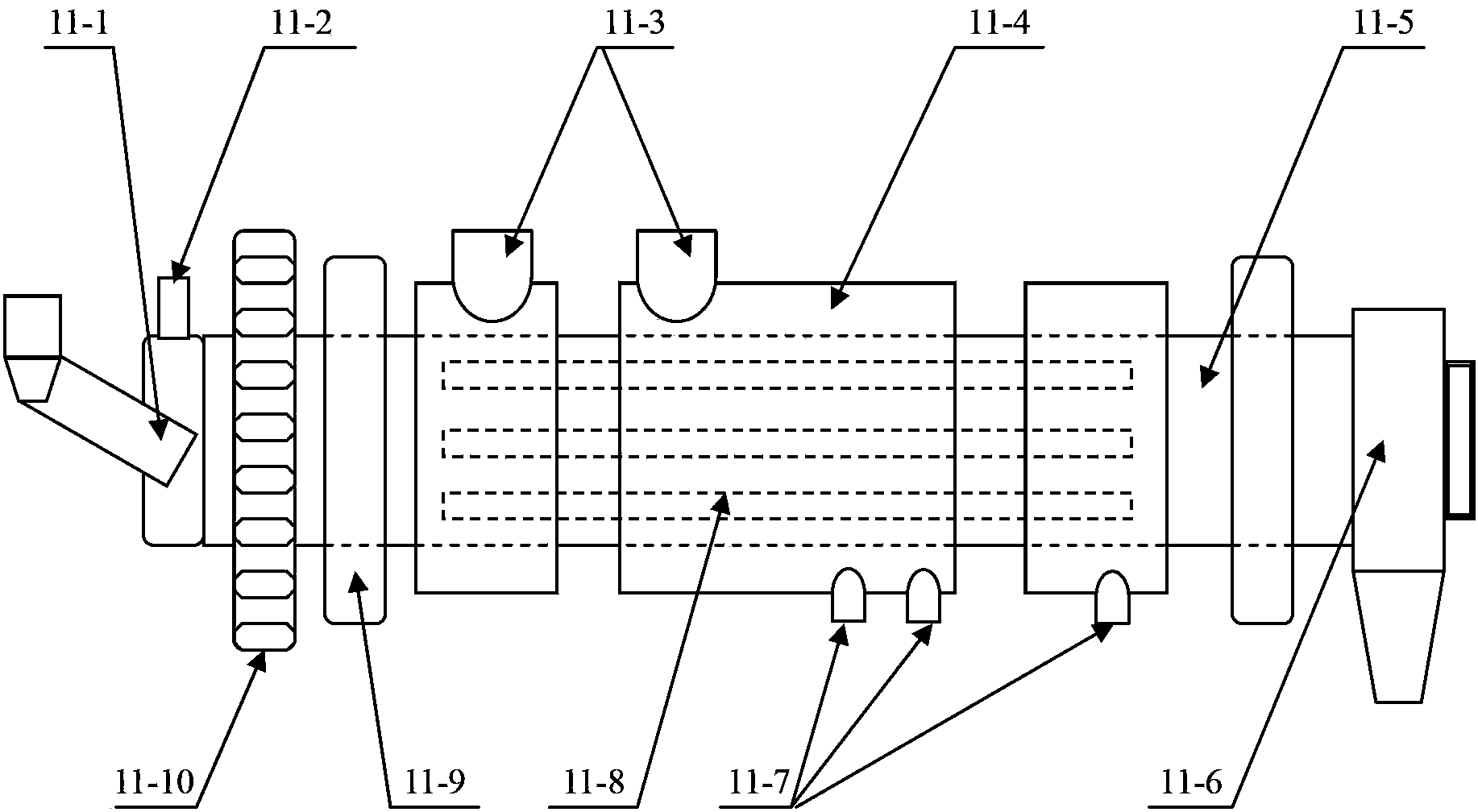

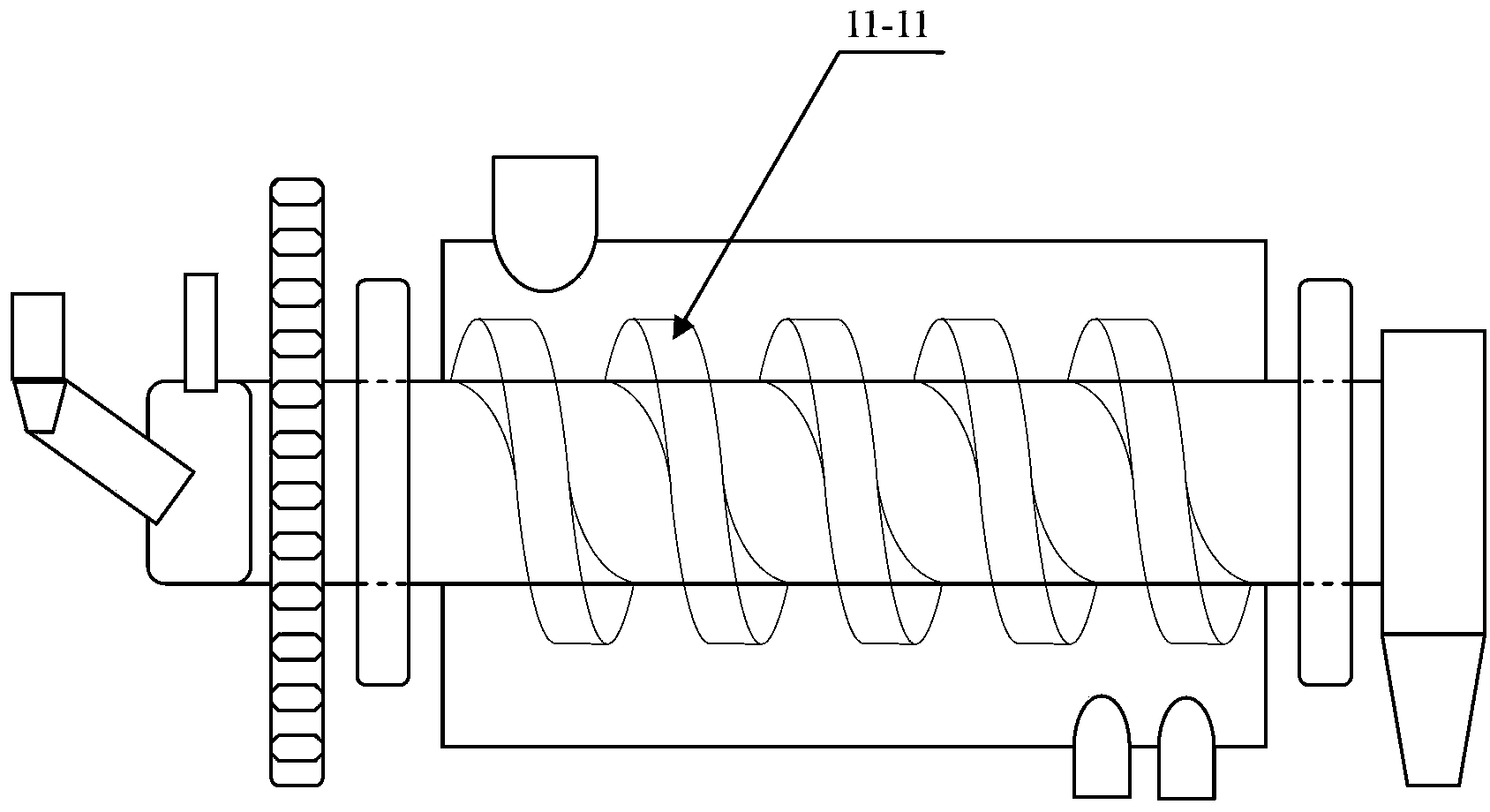

[0079] 3) The material sent into the rotary retort furnace is mixed with the 500°C tailings from the inner return screw that is 3 times the raw material at the front end of the retort furnace. The mixed material flows continuously to the end of the furnace, and the hot smoke is circulated through the external heating jacket The gas is heated an...

Embodiment 2

[0083] 1) Crushing and screening the raw oil shale to ≤6mm, the industrial analysis results of the raw oil shale used are as follows:

[0084]

[0085] 2) The raw material oil shale is sent to the raw material storage warehouse by the belt, and after being measured by the belt scale, it is sent to the steam tube drying furnace at a speed of 4.2t / h through the star feeder, so that the temperature of the raw material is preheated to 100°C and the moisture content Reduced to less than 0.5%, the material continuously moves to the end of the furnace with the rotation of the cylinder, and finally is discharged from the furnace body through the discharge box at the end of the furnace. The dust entrained in the dry tail gas is separated by a primary cyclone separator and a primary bag filter. ,collect.

[0086] 3) The oil shale after drying and preheating enters the rotary carbonization furnace from the star feeder through the chute, flows continuously to the end of the furnace wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com