Detection device for belt conveyor

A technology for detection devices and belt conveyors, applied in conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as detection deviations of external detection devices, achieve the effect of solving inaccurate speed measurement and ensuring good operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

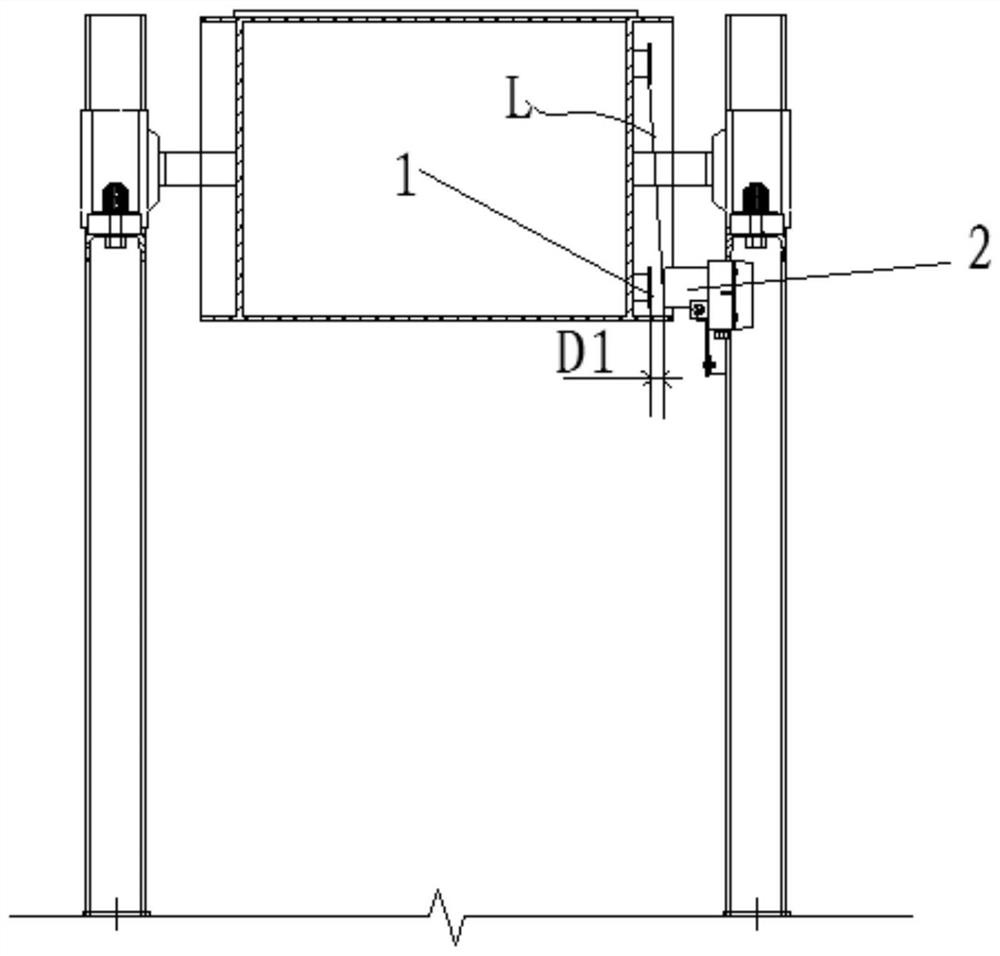

[0038]The belt conveyor consists of a belt, a driving pulley, a driven pulley and a bracket to support the pulley. The driving roller is driven by the motor, and the driven roller rotates under the friction of the belt.

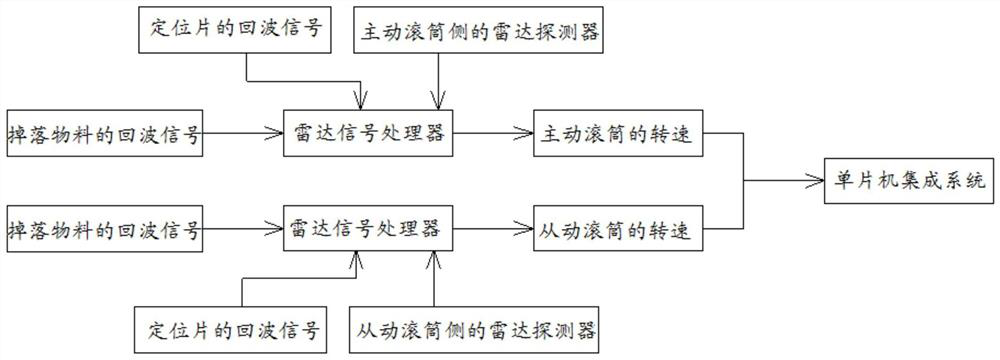

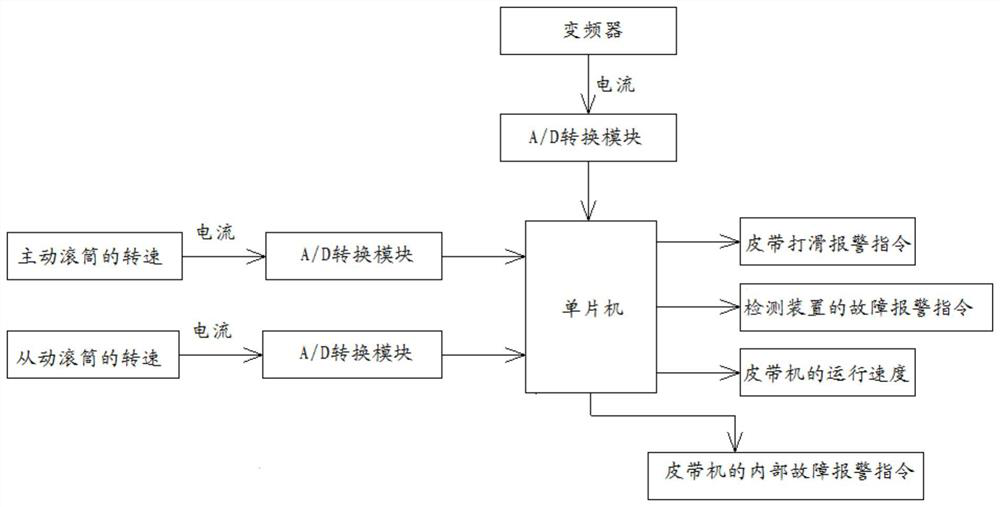

[0039] The detection device of the belt conveyor includes a detection unit and a single-chip microcomputer integrated system for detecting the rotating speed of the drum.

[0040] Specifically, two sets of detection units can be provided, one set is used to detect the rotation speed of the driving drum, and the other group is used to detect the rotation speed of the driven drum.

[0041] The detection unit includes a positioning part 1, a radar detector 2 and a radar signal processor.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com