Double-station sample collection device

A sample collection and double-station technology, applied in the direction of positioning device, feeding device, storage device, etc., can solve the problems of high cost and large space occupied by the collection structure, so as to reduce equipment cost, reduce occupied space, shorten The effect of the distance moved by the upper station

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]In order to make the purpose, technical solutions, and advantages of this application clearer, the following further describes this application in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the application, and not used to limit the application.

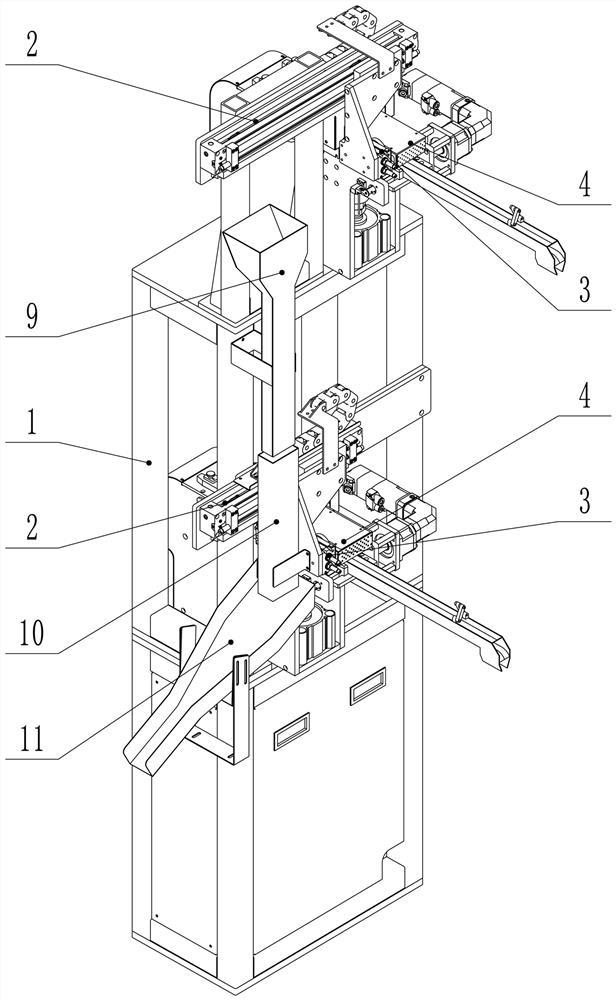

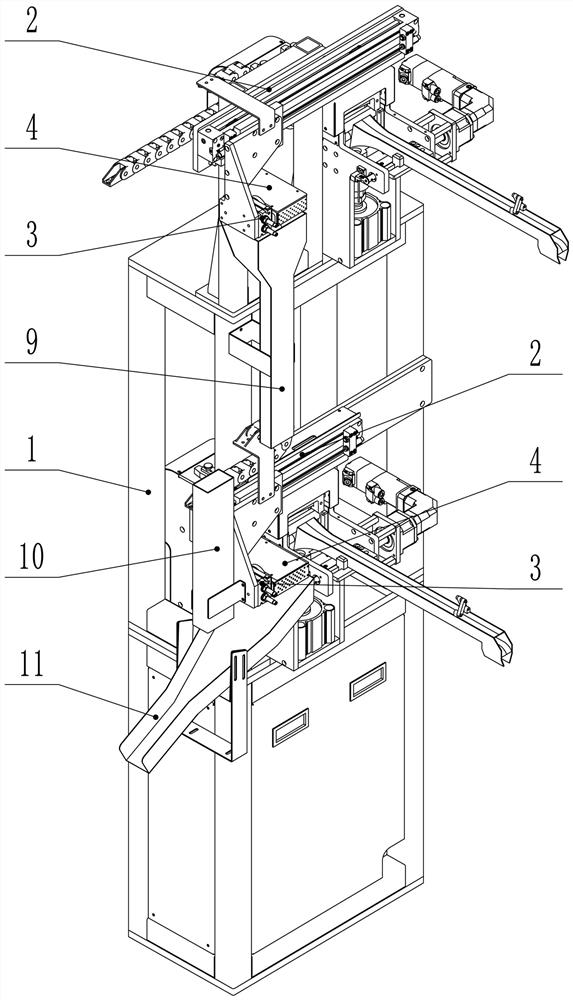

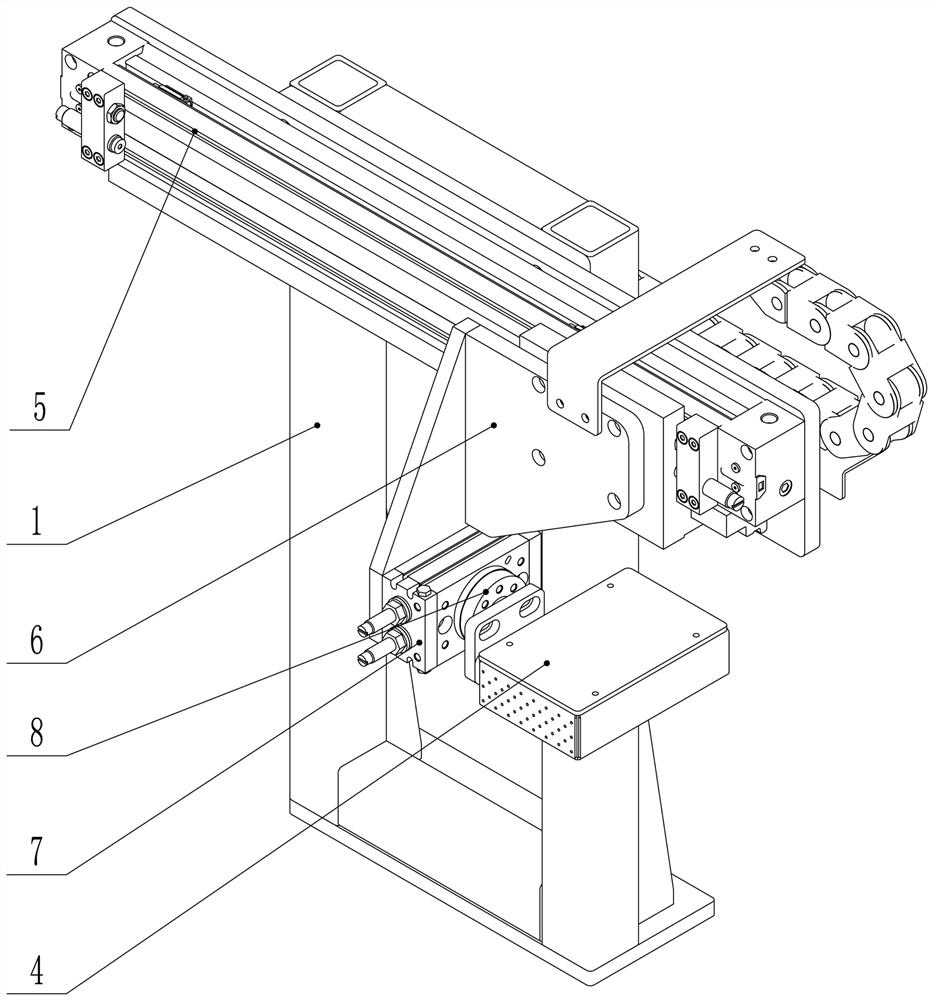

[0020]ReferenceFigure 1 to Figure 4, The double-station sample collection device of the present invention includes a frame 1. Two sets of reclaiming mechanisms are arranged up and down on the frame 1. The two sets of reclaiming mechanisms do not necessarily have to be vertically aligned. The specific position is based on the punching The completed material belt can be determined; the reclaiming mechanism includes a linear drive pair 2, a rotary drive pair 3 and a material box 4. The linear drive pair 2 can use common structures such as cylinders, linear motors, and motor screw pairs, and the rotary drive pair 3 Motors, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap