Crochet hook for stably implanting Z-direction fiber into composite material prefabricated body

A composite material and prefabricated technology, applied in the crochet field, can solve the problems of reducing Z-direction fiber efficiency and quality, fiber offset, etc., and achieve the effect of improving quality and efficiency, improving quality, and improving hooking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

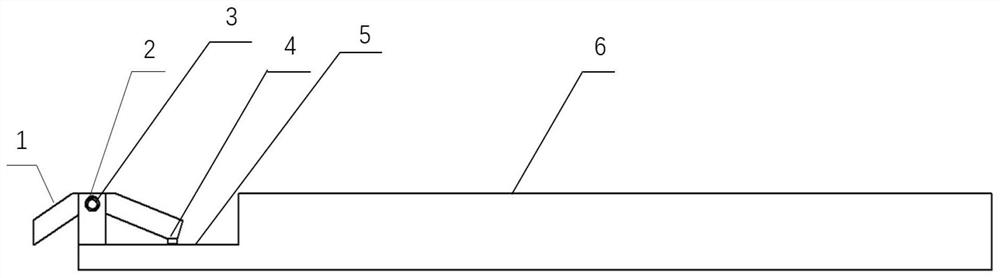

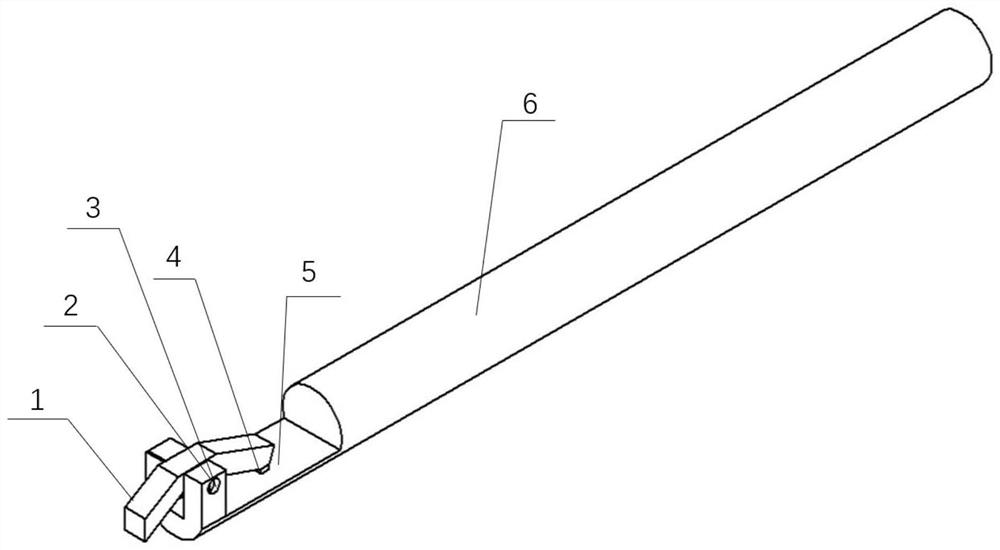

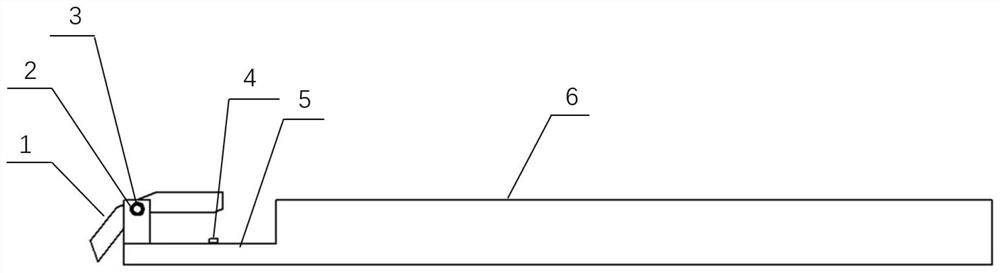

[0024] Reference attached figure 1 , in order to reduce the friction between the crochet hook and the composite material preform, the crochet hook is designed to be cylindrical. Before the crochet hooks enter the composite material prefabricated body, the front end of the Z-direction fiber closure plate interacts with the array steel needles, refer to the attached Figure 4 , due to the force on the front end of the closing plate, the closing plate will rotate under the action of the rotating shaft. After entering the prefabricated body, due to the restriction of the prefabricated body on the tilting displacement of the closing plate, the rear end of the Z-direction fiber closing plate is partially tilted, and along the crochet Move forward without scratchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com